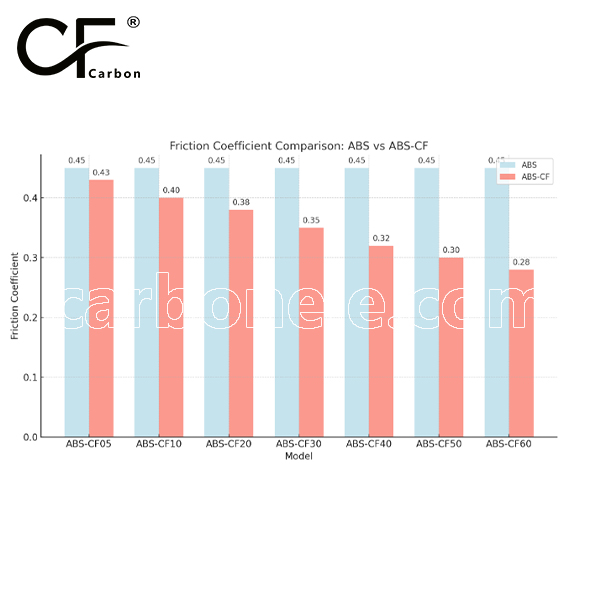

The friction coefficient of ABS is typically around 0.3 to 0.5, depending on surface finish and environmental factors. When carbon fibers are added to form ABS-CF, the friction coefficient generally decreases. The addition of carbon fibers can reduce the friction coefficient to about 0.2 to 0.4, as the fibers act as lubricants, improving wear resistance and lowering friction.The exact value can vary depending on the specific type of carbon fiber used, the proportion of carbon fiber in the composite, and the surface roughness of the materials involved.

ABS-CF10 Structural Plastic with Strength

Discover ABS-CF10 – a carbon fiber reinforced ABS material offering enhanced rigidity, dimensional stability, and heat resistance. Ideal for drone housings, automotive parts, electronics, and structural applications requiring strength and durability.

- Model number: ABS-CF-BCA6

- Matrix Resin: Acrylonitrile Butadiene Styrene (ABS)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

ABS-CF10 Structural Plastic with Strength

When durability meets lightweight efficiency, ABS-CF10 delivers unmatched value. This carbon fiber reinforced ABS material brings together the trusted versatility of ABS with enhanced structural performance, making it the perfect choice for engineers, designers, and manufacturers who need reliable strength without sacrificing ease of processing.

Whether you’re producing functional prototypes, precision housings, or load-bearing fixtures, ABS-CF10 offers a performance edge that standard plastics can’t match. With improved rigidity, better thermal stability, and an elevated professional appearance, this composite solution is a trusted performer in industries where material matters.

What is ABS-CF10?

ABS-CF10 is a composite thermoplastic made by reinforcing acrylonitrile butadiene styrene (ABS) with carbon fiber. The result is a material that retains the flexibility and processability of ABS while gaining a significant upgrade in mechanical performance. The addition of carbon fiber changes the behavior of the plastic, making it stiffer, stronger, and more suitable for structurally demanding environments.

This material is engineered for enhanced dimensional stability and impact resistance, making it a go-to solution for parts that must withstand mechanical stress while maintaining their form over time. It’s also ideal for producing parts that benefit from the sleek, matte surface appearance provided by the embedded carbon fibers.

Key Advantages of ABS-CF10

ABS-CF10 stands out because of its unique combination of processability, strength, and reliability. It bridges the gap between standard ABS and high-performance engineering plastics, providing a cost-effective option for upgrading part performance. Some of the key strengths of this material include:

-

Increased rigidity for structural performance

-

Enhanced dimensional stability under mechanical loads

-

Low warping during processing and cooling

-

Aesthetic surface finish with a modern carbon fiber texture

-

Improved resistance to wear and deformation over time

These characteristics make ABS-CF10 an ideal material for functional components that must combine strength with consistent form, especially in applications where parts experience long-term use or repeated assembly.

Typical Application: Durable Drone Housing Components

One of the most effective real-world uses of ABS-CF10 is in the production of drone body frames and housing components. These parts need to be lightweight, but also strong enough to resist mechanical stress during flight, landings, and rough handling. Traditional ABS can sometimes flex too much under stress, leading to deformation or failure under repeated use.

By switching to ABS-CF10, drone manufacturers are able to produce stronger body shells that maintain structural integrity while remaining light enough for efficient flight. The carbon fiber reinforcement helps reduce vibrations, adds stiffness to the frame, and contributes to the overall aesthetic of a premium, high-tech product.

Additionally, ABS-CF10 can be injection molded with tight tolerances, ensuring that each drone part fits precisely with motors, sensors, and other internal components. This reduces the risk of rattle, misalignment, or component shifting, which can significantly affect drone performance.

Suitable Across Multiple Industries

While drone manufacturing is a compelling example, the versatility of ABS-CF10 makes it suitable for a wide range of sectors:

-

Automotive: Used in interior panels, trim brackets, and functional clips that need strength without added weight

-

Consumer Electronics: Ideal for producing enclosures, protective cases, and structural frames for handheld devices or equipment

-

Robotics: Perfect for joint housings and support brackets that must endure constant movement

-

Industrial Tools: Used in casing parts or holders that require toughness and dimensional stability

-

3D Printing and Prototyping: Great for end-use parts or advanced prototypes that need to reflect production-level performance

This material is a strong candidate wherever standard ABS reaches its performance limits. Whether it’s mechanical stress, temperature cycles, or long-term use, ABS-CF10 holds up under pressure while staying cost-efficient and easy to manufacture.

Easy to Process, Hard to Replace

Despite its enhanced performance, ABS-CF10 retains the easy processing characteristics that make ABS such a popular base polymer. It works well in injection molding applications and can also be adapted for 3D printing or CNC machining in certain formats. This makes it a flexible solution for companies looking to scale production without significant investment in new tooling or techniques.

The carbon fiber content also helps reduce shrinkage and warping, resulting in consistent part dimensions even in large, complex molds. The matte finish from the carbon fiber blend adds a premium visual texture without the need for secondary treatments.

Why Choose ABS-CF10?

Choosing ABS-CF10 means choosing performance without complexity. It’s the practical upgrade for parts that need better stiffness, longer life, and improved stability, but without the high cost or processing challenges of more exotic engineering plastics.

For manufacturers, this means fewer returns, better part consistency, and improved customer satisfaction. For designers, it offers more freedom to innovate in shape and functionality without worrying about material failure. For end-users, it means products that feel solid, reliable, and built to last.

Conclusion

ABS-CF10 structural plastic delivers where it counts — in strength, stability, and reliability. Whether you’re improving an existing part or developing a new product, this material helps ensure your components are built to perform and engineered to last. From design table to production line, ABS-CF10 is your material of confidence.

If you want to get more information about ABS-CF10, you can visit our Youtube.

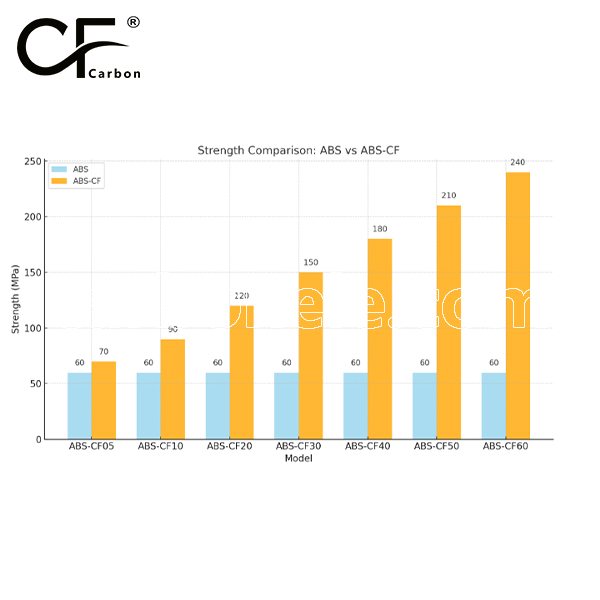

Strength between ABSand ABS-CF

ABS-CF (Carbon Fiber Reinforced ABS) offers a significant strength improvement over standard ABS. The addition of carbon fibers enhances ABS's tensile strength, impact resistance, and rigidity, making it more suitable for high-load and demanding environments. ABS-CF also exhibits better flexural strength and heat resistance compared to standard ABS, making it ideal for applications requiring higher strength and durability.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.