Exploring the Realm of PP CF Reinforced Composites

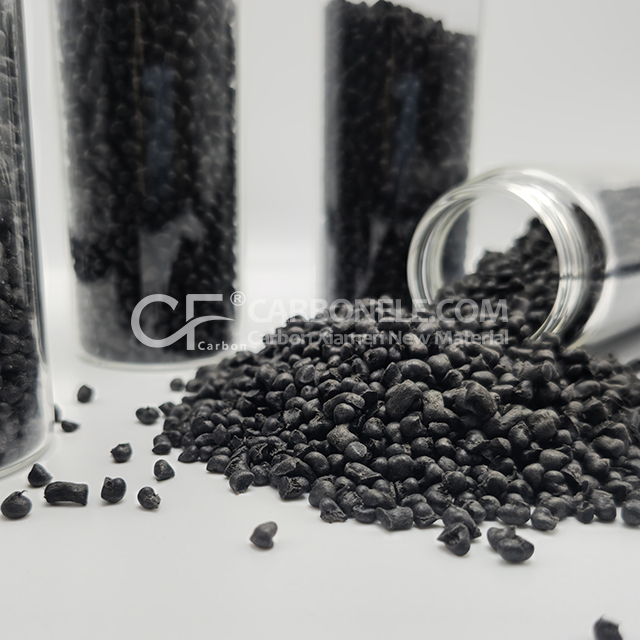

PP CF Reinforced Composites refer to composites in which polypropylene (PP) is reinforced with carbon fibers (CF). PP Carbon Fiber Reinforced Composites have remarkable characteristics. Firstly, there is a significant improvement in strength, enabling them to withstand higher loads. Secondly, the stiffness is enhanced, making them less prone to deformation and having excellent structural stability. Moreover, they have good heat resistance and can maintain stable performance in high-temperature environments. At the same time, compared to pure polypropylene, they are lighter, which helps reduce the overall weight.

In terms of applications, due to their excellent performance, they are widely used in the automotive industry. They are used to manufacture automotive components, such as body structural parts, which can not only reduce the vehicle weight and improve fuel efficiency but also ensure strength and safety. They are also favored in the aerospace field and can be used to make structural parts inside aircraft. In addition, they are applied in the manufacturing of sports equipment, such as the frames of high-performance bicycles. In the field of electronic devices, they can be used to make shells, providing good mechanical properties and protection. In conclusion, PP CF Reinforced Composites play an important role in many fields and have broad application prospects with their unique performance advantages.

Product By Features

PP-CF10 High-Stiffness – Machinery

PP-CF10 carbon fiber reinforced polypropylene is a high-performance composite material offering exceptional stiffness, lightweight properties, and corrosion resistance. Ideal for industrial machinery, automotive, and outdoor applications

Learn More

Weatherproof PP-CF10 – Outdoor

PP-CF10 carbon fiber reinforced polypropylene is an advanced composite material engineered for superior outdoor durability. Combining polypropylene’s weather resistance with carbon fiber reinforcement, this high-performance material delivers exceptional strength, UV resistance, and dimensional stability. Ideal for outdoor furniture, sports equipment, and architectural components, PP-CF10 withstands extreme temperatures, moisture, and prolonged…

Learn More

Flame Retardent PP-CF30-FR Thermoplastic Compos...

PP-CF30-FR composites achieve a breakthrough balance of fire safety, mechanical strength, and functional properties through the synergistic optimization of high-content carbon fiber reinforcement and nano-scale flame-retardant systems, providing revolutionary material solutions for new energy and high-end electronics applications.

Learn More

Flame retardency Grade FR PP CF20 PP-CF-BCF Com...

Engineered for safety & strength! FR PP CF20 composites deliver UL94 V-0 flame resistance, 200% stronger than standard PP, and superior dimensional stability – the ultimate lightweight solution for EV batteries and electronics.

Learn More

Flame-retardent Polypropylene PP CF Composites ...

Flame-retardant polypropylene PP CF composites achieve an optimal balance of safety, strength, and cost through flame-retardant and reinforcement modifications, making them ideal replacements for traditional engineering plastics in electronics.

Learn More

Polypropylene PP CF FR Composites for 3D Printe...

Unlock next-gen 3D printing with PP CF FR composites! Engineered for superior strength, flame resistance and dimensional stability – the ultimate filament for demanding industrial applications.

Learn More

MFI MFR 12 PP CF20 for Extruding Carpet Backing

1.12 MFR flow for smooth extrusion 2.4500MPa stiffness(3x pure PP) 3. 1.12g/cm* density(20% lighter) 4. <0.5 strands/m² surface quality 5.25m/min speed (22% faster output)

Learn More

Extrusion Grade MFI 12 PP CF for Extruding Mach...

1. High flowability (MFI 12) for smooth extrusion processing 2.80-100 MPa tensile strength with 20% carbon fiber 3.120°℃ HDT for enhanced thermal resistance 4. Optimized fiber dispersion at 180-220C processing 5.15-25 MPa extrusion pressure for energy efficiency

Learn More

Granular PP CF20 Materials for 3D Printer Engin...

PP CF20 Materials combine the lightweight, chemical-resistant properties of PP with the enhanced strength and stiffness provided by carbon fiber, making it ideal for functional prototypes and end-use parts in automotive, aerospace, and industrial applications.

Learn More

Pellet-based PP-CF30 Granules for FGF 3D Printi...

PP-CF30 granules are tailored for FGF-printed large-format components requiring lightweight durability, such as: *Automotive: Jigs, fixtures, and non-structural body panels. *Aerospace: Tooling and cabin interior prototypes. *Industrial: Custom pallets and robotic end-effectors.

Learn More

Electric Conductive CF40-PP Composites for Ligh...

Electric Conductive CF40-PP Composites combine polypropylene with 40% carbon fiber, offering high electrical conductivity (10²–10⁴ Ω·cm), lightweight strength (80–120 MPa), and thermal stability (HDT ~150°C). Used in EMI shielding, automotive, and aerospace, they provide corrosion resistance and easy processing via injection molding.

Learn More

Polypropylene PP-CF-EPDM TD20 Raw Materials for...

PP-CF-EPDM TD20 is a reinforced polypropylene composite with 20% mineral filler (TD20), carbon fiber (CF) for strength, and EPDM for toughness. It offers high rigidity, impact resistance, thermal stability, and lightweight properties. Common applications include automotive parts, electronics housings, and industrial components. Suitable for injection molding with optimized processing conditions.

Learn MoreProduct Feature Box

ECO FRIENDLY

ABRASION RESISTANCE

LIGHT WEIGHT

WEAR RESISTANCE

CONDUCTIVE MATERIALS

HIGH STRENGTH

SCRATCH RESISTANCE

ANTI STATIC

Company Advantage

Stringent Quality Control System

Carbon (Xiamen) New Material has a comprehensive quality inspection process in place, from raw material selection to finished product delivery. In raw material procurement, high-precision tests are done. During production, each step is monitored and sampled. Non-destructive testing checks for defects in finished products. This meticulous approach, coupled with continuous improvement efforts based on quality data analysis, ensures that every product leaving the factory meets or exceeds the most stringent industry standards.

Rich Industry Experience

Years of involvement give Carbon (Xiamen) New Material production and trade knowledge. It supplies to major projects, enhancing skills and reputation. Active in global events, it keeps up with trends and gains information for growth. By leveraging this experience, the company is able to anticipate market shifts and proactively adjust its strategies and product offerings to stay relevant and competitive.

Customization Production Capacity

Carbon (Xiamen) New Material is flexible and can meet unique customer demands. For aerospace, it uses advanced design and simulation for complex, high-performance parts. For the automotive industry, it combines strength with aesthetic and surface treatment. By closely collaborating with customers at every stage of the production process and leveraging its technical expertise, the company ensures that the final product precisely aligns with the customer's specifications and expectations.

Professional R & D Team

Carbon (Xiamen) New Material has a team of experienced material scientists, engineers, and technical experts. They innovate and improve products. Material scientists enhance interfaces, engineers optimize designs, and experts use tech for monitoring and efficiency. The team actively participates in industry conferences and workshops, fostering a culture of learning and knowledge sharing, which leads to continuous improvement in product development and process optimization.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

What makes PP CF Reinforced Composites different from other composites?

PP CF Reinforced Composites stand out due to their combination of lightweight nature, enhanced strength and stiffness, and good heat resistance compared to many other composites.

-

How is the processability of PP CF Reinforced Composites?

The processability of these composites is relatively good. They can be molded and fabricated using various standard processing techniques, making them suitable for a wide range of manufacturing processes.

-

Are PP CF Reinforced Composites environmentally friendly?

They have some eco-friendly aspects, such as their potential for recyclability and reduced material usage due to their high performance, which can lead to less waste over time.

-

Can PP CF Reinforced Composites be used in consumer products?

Yes, they can be used in various consumer products like high-quality sports equipment and some advanced electronic devices where strength and lightweight are crucial.

-

What are the cost considerations for PP CF Reinforced Composites?

The cost of PP CF Reinforced Composites is typically higher than plain polypropylene, but the improved performance and potential for longer lifespan can offset the initial investment in certain applications.