PEI CF: Breaking Through Conventional Properties & Applications

Performance characteristics: - High strength and modulus: Significantly enhance the material's strength and stiffness when combined with polyetherimide, offering excellent load-bearing capacity. - Good heat resistance: Can maintain performance at high temperatures due to the properties of both polyetherimide and carbon fibers. - Low density: Facilitates lightweight design compared to traditional metals. - Good corrosion resistance and durability: Remains stable in harsh environments. - Strong designability: Customizable to meet different application needs. - Good impact resistance: Absorbs energy and maintains structural integrity upon impact. - Excellent electrical performance: Stable in various conditions, applicable in fields with high electrical requirements. - Good dimensional stability: Resists deformation with temperature changes. - Good fatigue resistance: Ideal for components subjected to repeated loads. - Good processing performance: Can be molded into various shapes and sizes.

Main application fields: 1. Aerospace: Manufacturing aircraft components due to its high strength and temperature resistance. 2. Automotive: Used for various parts due to heat and chemical resistance. 3. Electronics: Producing components like connectors and circuit boards. 4. Sports goods: Meeting weight and strength demands. 5. Industrial: Making equipment parts like pump impellers. 6. Medical devices: Manufacturing surgical instrument components. 7. Protective equipment: Crafting key protective gear components. 8. High-end manufacturing: Ensuring high precision and performance in advanced equipment. The application fields may expand and innovate with technological progress. Practical selection considers factors like performance, cost, and processing technology.

Product By Features

Mechanical Properties PEI-CF60

PEI-CF60 is a high performance thermoplastic reinforced with 60% carbon fiber, offering exceptional stiffness, strength, and wear resistance. With excellent thermal and chemical resistance, it excels in extreme, high-stress environments. Ideal for aerospace, automotive, electronics, and industrial applications, PEI-CF60 provides superior durability while remaining easy to process through injection molding…

Learn More

Carbon Fiber Reinforced Plastic PEI-CF50

PEI-CF50 is a high performance thermoplastic reinforced with 50% carbon fiber, offering exceptional stiffness, strength, and wear resistance. With outstanding thermal and chemical resistance, it excels in extreme, high-stress environments. Ideal for aerospace, automotive, electronics, and industrial applications, PEI-CF50 provides excellent durability while remaining processable via injection molding and extrusion.

Learn More

PEI-CF40 Carbon Fiber Reinforced Plastic

PEI-CF40 is a high performance thermoplastic reinforced with 40% carbon fiber, offering exceptional strength, wear resistance, and chemical stability. Ideal for extreme, high-stress environments, it performs well in aerospace, automotive, and electronics applications. It also boasts excellent thermal resistance and low moisture absorption, with easy processing via injection molding and…

Learn More

PEI-CF30 Unrivaled Strength Longevity

PEI-CF30 is a high-performance thermoplastic reinforced with 30% carbon fiber, offering exceptional strength, stiffness, wear resistance, and thermal stability. Ideal for extreme-duty applications in automotive, aerospace, and medical devices, it excels in environments with high mechanical loads, temperatures, and chemical exposure while maintaining excellent dimensional stability.

Learn More

Unrivaled Strength Longevity PEI-CF20

PEI-CF20 is a high-performance thermoplastic reinforced with 20% carbon fiber, offering exceptional strength, stiffness, and wear resistance. It maintains excellent thermal and chemical properties, making it ideal for demanding applications in automotive, aerospace, and medical devices where high mechanical loads, extreme temperatures, and chemical exposure are involved.

Learn More

PEI-CF05 Maximum Strength Endurance

PEI-CF05 is a high-performance thermoplastic reinforced with 5% carbon fiber, offering balanced mechanical strength, enhanced wear resistance, and excellent thermal and chemical stability. It is ideal for moderate-duty applications in automotive, aerospace, and industrial sectors, where reliable performance under moderate temperatures and chemical exposure is required. PEI-CF05 maintains low moisture…

Learn More

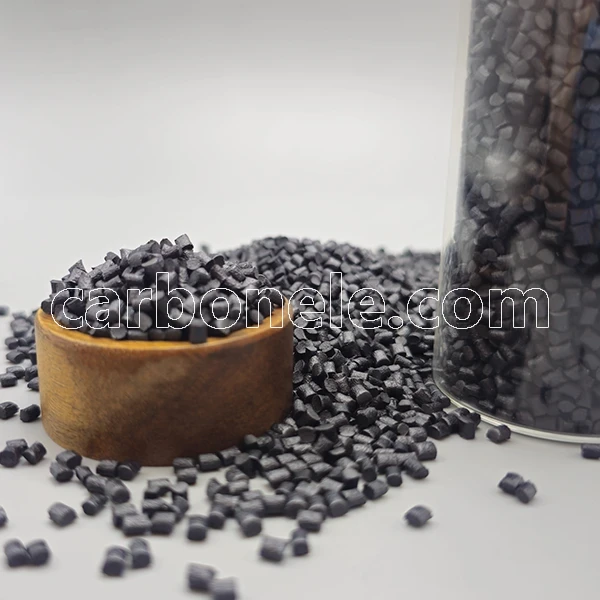

PEI CF Raw Materials Carbon Fiber Reinforced PE...

PEI CF60 has excellent mechanical properties, outstanding heat resistance, good flame retardancy, superior electrical properties, chemical resistance and certain processability, used to manufacture a variety of products, such as mechanical transmission parts and electronic equipment casings.

Learn More

50% Carbon Fiber PEI Compounds for Drone Fuselages

50% Carbon Fiber PEI Compounds are remarkable thermoplastics with 50% carbon fiber. They combine PEI’s properties with carbon fibers, boosting rigidity and reducing weight. Essential in demanding scenarios, they’re vital in aerospace and automotive, and contribute in high-tech engineering.

Learn More

High Strength PEI CF20 for Aircraft Undercarria...

PEI CF20 is a thermoplastic composite. Composed of PEI and 20% carbon fiber, it has high strength, heat resistance, and good chemical resistance. It’s preferred in industries like aerospace and automotive.

Learn More

High-performance PEI CF10 for Exploration Equip...

PEI CF10 possesses numerous outstanding traits such as exceptional abrasion resistance, high tensile strength, lightness and portability, resistance to seawater corrosion, impact and collision, chemical attack, high-temperature tolerance, low water absorption, favorable electrical insulation, and high dimensional stability, rendering it highly appropriate for diverse exploration applications.

Learn More

High-temperature Resistance PEI CF40 for Aerosp...

PEI CF40 ingeniously combines the high-performance attributes of PEI with the unrivaled strength and rigidity of carbon fiber. The result is a material that is exceptionally well-suited for a wide array of high-demand applications, driving innovation and performance in various industries.

Learn More

Carbon Fiber Reinforced Thermoplastics PEI CF30...

PEI CF30 is a 30% carbon fiber-reinforced composite. It has strong mechanical strength and stiffness, good thermal stability, chemical resistance, and is easy to mold. Its low weight is an advantage. It’s valuable in many industries.

Learn MoreProduct Feature Box

ECO FRIENDLY

ABRASION RESISTANCE

SCRATCH RESISTANCE

LIGHT WEIGHT

CONDUCTIVE MATERIALS

HIGH STRENGTH

WEAR RESISTANCE

ANTI STATIC

Company Advantage

Advanced Production Technology

Carbon (Xiamen) New Material Co., Ttd. is equipped with state-of-the-art carbon fiber composite production processes and advanced equipment. It has highly automated layup devices for precise fiber control, ensuring mechanical property consistency. Advanced curing methods like vacuum-assisted or autoclave curing improve efficiency and product quality. The company also regularly invests in research and development to introduce innovative production techniques, enhancing its ability to meet diverse customer needs and stay ahead in the competitive market.

Efficient Supply Chain Management

Carbon (Xiamen) New Material has a mature supply chain that ensures raw material supply and on-time product delivery. Close ties with global suppliers guarantee quality. Cooperation with logistics experts ensures fast transportation. Real-time tracking predicts and resolves issues. The company also maintains a buffer stock of critical raw materials to mitigate supply chain disruptions and has contingency plans in place to handle unforeseen circumstances promptly.

Excellent After-sales Service

Carbon (Xiamen) New Material offers all-round, prompt, and professional after-sales support. A dedicated team responds within 24 hours. They solve problems remotely or on-site and provide installation and maintenance training. Feedback is used to improve service. The company also establishes long-term relationships with customers by providing regular maintenance checks and updates, ensuring the longevity and optimal performance of its products.

Export Qualifications and Certifications

Carbon (Xiamen) New Material has export qualifications and international certifications like ISO 9001 and AS9100. These boost product recognition and competitiveness, opening doors to high-end markets and various industries. It is constantly working towards obtaining additional certifications and adhering to the latest industry standards to expand its market presence and meet the evolving demands of global customers.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

What are PEI CF Reinforced Composites?

PEI CF Reinforced Composites are a type of advanced material composed of Polyetherimide (PEI) matrix reinforced with Carbon Fiber (CF). They offer enhanced mechanical properties, such as high strength and stiffness, as well as improved thermal and chemical resistance. For example, they are commonly used in aerospace and automotive industries for lightweight and high-performance components.

-

What are the advantages of PEI CF Reinforced Composites over traditional materials?

The advantages include superior mechanical strength, lighter weight, better heat resistance, and higher chemical stability. This makes them suitable for applications where performance and durability are crucial. Take the aerospace sector, where using these composites in aircraft parts can lead to fuel savings and increased safety.

-

How are PEI CF Reinforced Composites manufactured?

The manufacturing process typically involves techniques like injection molding, compression molding, or filament winding. In injection molding, the PEI and CF mixture is heated and injected into a mold. Compression molding applies pressure and heat to form the composite. Filament winding involves winding the CF impregnated with PEI onto a mandrel.

-

What are the common applications of PEI CF Reinforced Composites?

They are widely used in aerospace for structural components, automotive for engine parts, sports equipment for enhanced performance, and in the medical field for precise and durable devices. For instance, in the medical field, they can be used to make prosthetics that are both strong and lightweight.

-

How to maintain and repair PEI CF Reinforced Composites?

Maintenance usually involves regular inspection for damage or wear. Repair methods depend on the extent of the damage but may include patching or replacing the affected area. Specialized adhesives and repair techniques are often required. If a small crack occurs, it can be filled with a compatible resin and cured properly.

-

What are the challenges in working with PEI CF Reinforced Composites?

Challenges include the high cost of raw materials, complex processing requirements, and difficulties in recycling. The complex nature of the material can also pose challenges in quality control during manufacturing. For example, achieving uniform distribution of carbon fibers within the PEI matrix can be tricky and affect the final properties of the composite.