Decoding PBT CF Reinforced Composites

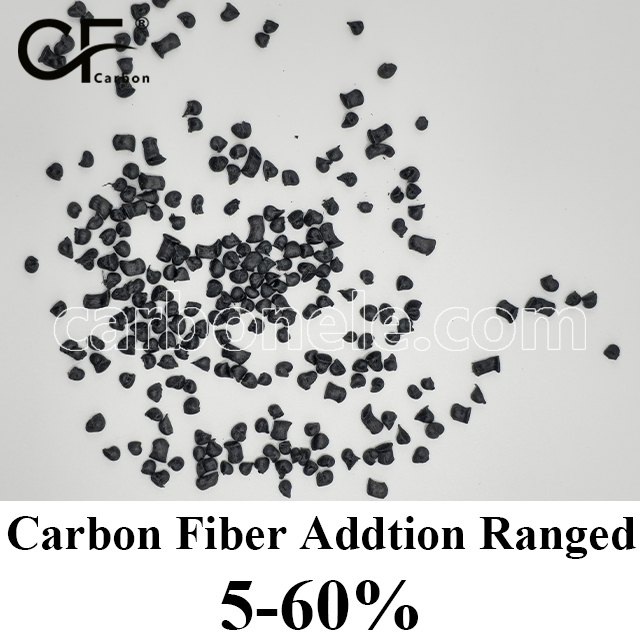

"PBT CF Reinforced Composites" refers to polybutylene terephthalate (PBT) carbon fiber reinforced composites. PBT itself is an engineering plastic with good mechanical properties, heat resistance and electrical properties. And carbon fibers have the characteristics of high strength, high modulus and low weight.

When carbon fibers are used to reinforce PBT, the formed composites greatly improve the strength, stiffness and heat resistance on the basis of maintaining the original advantages of PBT, enabling it to be used under more demanding conditions and widely used in fields such as automotive parts, electronic appliances, aerospace, etc. For example, parts around the automotive engine, shells of high-performance electronic devices, etc.

Product By Features

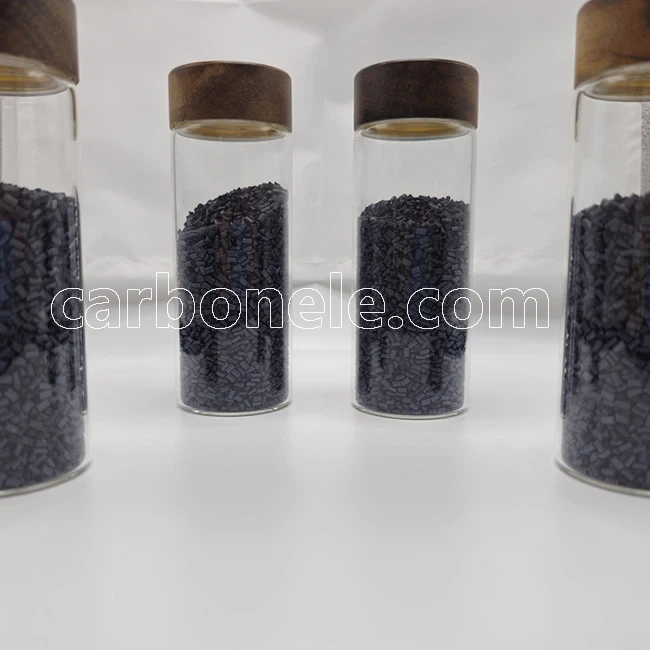

Custom carbon fiber parts PBT-CF60

PBT-CF60 is a high performance thermoplastic with 60% carbon fiber, offering exceptional tensile strength (≥ 220 MPa), flexural strength (≥ 400 MPa), and wear resistance. It performs well in extreme temperatures (HDT ~320°C) and provides excellent chemical resistance, making it ideal for automotive, industrial, electronics, and household applications requiring maximum…

Learn More

PBT-CF50 Custom carbon fiber parts

PBT-CF50 is a high performance thermoplastic with 50% carbon fiber, offering exceptional tensile strength (≥ 200 MPa), flexural strength (≥ 350 MPa), and wear resistance. It performs well in high temperatures (HDT ~300°C) and provides excellent chemical resistance. Ideal for automotive, industrial, electronics, and household applications requiring superior durability and…

Learn More

PBT-CF40 Carbon fiber plastic parts

PBT-CF40 is a high strength thermoplastic with 40% carbon fiber, offering exceptional mechanical properties, wear resistance, and chemical stability. It performs well in high temperatures (HDT ~280°C) and is ideal for demanding automotive, industrial, and electronic applications.

Learn More

Carbon fiber plastic parts PBT-CF30

PBT-CF30 is a carbon fiber reinforced plastic offering enhanced stiffness, strength, and wear resistance compared to unreinforced PBT. With 30% carbon fiber, it is ideal for high performance applications exposed to mechanical loads, elevated temperatures, and chemicals. It offers excellent durability, wear resistance, and dimensional stability in demanding environments, making…

Learn More

Carbon Fiber Reinforced Polypropylene PBT-CF20

PBT-CF20 is a polybutylene terephthalate (PBT) reinforced with 20% carbon fiber, offering enhanced stiffness, strength, and wear resistance. It is ideal for high-performance applications under elevated mechanical loads, with excellent thermal and chemical resistance, and good dimensional stability. Suitable for automotive, industrial, electronics, and household components, PBT-CF20 combines durability and…

Learn More

Carbon Fiber Reinforced Polypropylene PBT-CF10

PBT-CF10 is a polybutylene terephthalate (PBT) reinforced with 10% carbon fiber, offering enhanced stiffness, strength, and wear resistance compared to unreinforced PBT. It is suitable for applications requiring moderate to high mechanical loads, performing well in temperatures up to 220°C and resisting a variety of chemicals. PBT-CF10 is ideal for…

Learn More

PBT-CF05 Carbon Fiber Reinforced Polypropylene

PBT-CF05 is a polybutylene terephthalate (PBT) reinforced with 5% carbon fiber, offering improved stiffness and strength for moderate mechanical loads. It performs well in temperatures up to 210°C and resists a variety of chemicals. Ideal for automotive, industrial, electronics, and household applications, it is processable via injection molding and extrusion.

Learn More

Good Heat Resistance PBT CF Plastic PBT CF60 Ra...

PBT CF60 features high strength and rigidity, good impact resistance, excellent heat resistance and high heat distortion temperature. It also has good electrical insulation, low dielectric constant and loss.

Learn More

5% Carbon Fiber Reinforced PBT CF5 Plastic Raw ...

PBT CF5 has high strength (tensile strength up to 150 MPa), high modulus, good heat resistance (up to 160°C), low shrinkage rate, excellent electrical conductivity, strong corrosion resistance, is lightweight, and good wear resistance.

Learn More

Virgin PBT CF50 PBT-CF 50% Carbon Fiber Reinfor...

PBT-CF 50 has high strength to withstand heavy loads, good rigidity for stability, heat resistance for use in moderately high temps, low thermal expansion, chemical resistance and is lightweight yet strong, making it ideal for many industrial applications.

Learn More

High Quality PBT CF20 for Home Devices – ...

PBT CF20 is a blend of PBT and 20% carbon fiber. It notably boosts mechanical strength, rigidity, and thermal resistance. Widely employed in automotive and aerospace, it offers superior stability and significantly reduces weight, enhancing performance.

Learn More

Best Price Per KG PBT CF40 China Supplier

PBT CF40 is a specialized thermoplastic. It combines high performance and durability. The carbon fiber reinforcement boosts its properties. Key features include mechanical strength, thermal stability, chemical resistance, and dimensional stability. It’s used in automotive, electrical, industrial, and consumer goods. Consider factors for best price and quality.

Learn MoreProduct Feature Box

WEAR RESISTANCE

CONDUCTIVE MATERIALS

HIGH STRENGTH

ANTI STATIC

SCRATCH RESISTANCE

ABRASION RESISTANCE

ECO FRIENDLY

LIGHT WEIGHT

Company Advantage

Innovation Capacity

Being able to continuously introduce novel products, services or solutions to meet the constantly changing market demands, thus standing out in the competition.

Cost Control Ability

Effectively controlling costs by optimizing operational processes, reducing raw material costs, improving production efficiency, etc., thereby gaining an advantage in price competition.

Efficient Supply Chain Management

Ensuring the timely supply of raw materials, optimizing the production process, reducing inventory costs, and achieving rapid product delivery.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

What are the main advantages of PBT CF Reinforced Composites?

PBT CF Reinforced Composites offer enhanced mechanical strength, increased stiffness, improved heat resistance, and better dimensional stability compared to plain PBT.

-

In which industries are PBT CF Reinforced Composites commonly used?

They are commonly used in the automotive, aerospace, electronics, and industrial machinery industries for components that require high performance and durability.

-

How does the addition of carbon fiber affect the properties of PBT?

The addition of carbon fiber significantly boosts the strength and stiffness of PBT, reduces its thermal expansion, and enhances its fatigue resistance.

-

What processing methods are suitable for manufacturing products with PBT CF Reinforced Composites?

Injection molding, extrusion, and compression molding are commonly used processing methods for these composites.

-

Are PBT CF Reinforced Composites expensive compared to traditional materials?

They can be more costly than some traditional materials, but their superior properties and performance often justify the higher cost in applications where high performance is crucial.

-

How do environmental factors affect the performance of PBT CF Reinforced Composites?

Environmental factors such as moisture, UV radiation, and chemical exposure can have a limited impact on their properties, but proper surface treatments and additives can improve their resistance.