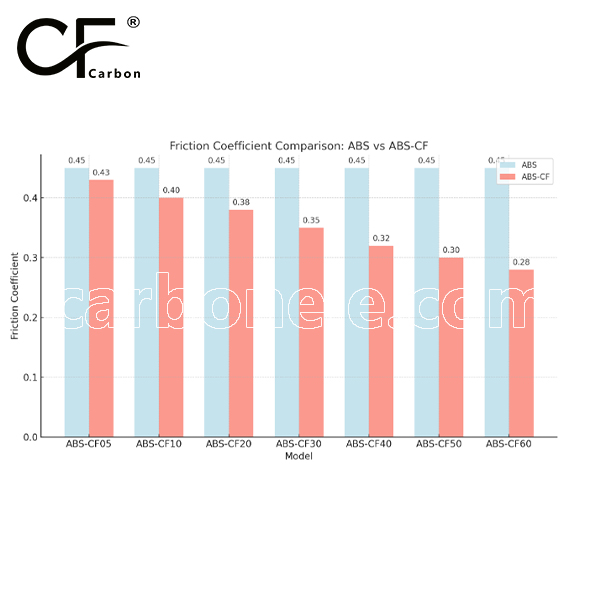

The friction coefficient of ABS is typically around 0.3 to 0.5, depending on surface finish and environmental factors. When carbon fibers are added to form ABS-CF, the friction coefficient generally decreases. The addition of carbon fibers can reduce the friction coefficient to about 0.2 to 0.4, as the fibers act as lubricants, improving wear resistance and lowering friction. The exact value can vary depending on the specific type of carbon fiber used, the proportion of carbon fiber in the composite, and the surface roughness of the materials involved.

ABS-CF20 2X Toughness for Auto Interiors

Discover ABS-CF20, a carbon fiber-reinforced ABS composite offering 2X toughness for automotive interiors. Enhance durability, dimensional stability, and aesthetics in dashboards, door trims, and more—ideal for lightweight, high-performance designs.

- Model number: ABS-CF-BCA2

- Matrix Resin: Acrylonitrile Butadiene Styrene (ABS)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Introduction to ABS-CF20

ABS-CF20 is a modern material that blends the well-known reliability of ABS with the advanced reinforcement of carbon fiber. The result is a composite that offers a significant increase in toughness while maintaining the lightweight nature that designers and engineers demand for automotive interiors. This combination gives ABS-CF20 a distinctive position in the market, appealing to manufacturers seeking both performance and style.

Why ABS-CF20 Stands Out in Automotive Interiors

Strength-to-Weight Superiority

ABS-CF20 combines high strength with low weight, a combination that is particularly important for automotive interiors. Reducing weight helps improve overall vehicle efficiency, while maintaining strength ensures that components can withstand regular use and occasional impacts without deformation. This balance makes ABS-CF20 a favored choice for high-end vehicle interiors where both aesthetics and durability are equally important.

Exceptional Dimensional Stability

Changes in temperature and humidity can cause some materials to warp or lose shape. ABS-CF20 resists such changes, ensuring that interior panels, trims, and consoles retain their intended dimensions over time. This stability is vital in creating tight-fitting components that do not loosen, squeak, or rattle during the lifetime of the vehicle.

Refined Aesthetics

The carbon fiber reinforcement in ABS-CF20 gives it a distinctive appearance that can be showcased in visible components. It offers a sleek, premium look without requiring additional surface treatments. For designers seeking a modern or sporty interior feel, ABS-CF20 offers both performance and visual appeal.

Real-World Application: Dashboard Panels

Durability and Impact Resistance

Dashboard panels are central to the driver’s experience and must resist daily handling, sunlight exposure, and temperature fluctuations. ABS-CF20 provides the necessary toughness to endure these stresses without losing integrity. Its impact resistance ensures that minor bumps or knocks do not cause cracks or deformation.

Stable Fit and Finish

Precision is essential in dashboard design. ABS-CF20’s dimensional stability allows for consistent panel alignment, preserving the clean lines of the interior. This helps maintain the quality feel of the vehicle, even after years of use.

Surface Quality

A dashboard must be visually appealing. ABS-CF20 allows for a fine surface finish that feels pleasant to the touch and complements other interior materials. Whether textured or smooth, the surface maintains its appearance with minimal maintenance.

Applications Beyond the Dashboard

Door Trim Panels

ABS-CF20 provides the rigidity needed for door trims, ensuring they stay securely in place while offering a comfortable touch for passengers. The material’s toughness helps resist damage from repeated door closing and contact with shoes or luggage.

Center Consoles

Center consoles see constant use for storage and as a functional space for controls. ABS-CF20 ensures that these parts remain solid and scratch-resistant, even with heavy usage.

Seat Back Covers

Seat back covers often face impacts from passengers’ feet or cargo. ABS-CF20’s strength allows these components to withstand such treatment while keeping a refined appearance.

Processing Advantages of ABS-CF20

Injection Molding Compatibility

ABS-CF20 works well with standard injection molding processes, making it easy for manufacturers to adopt without extensive retooling. This compatibility also allows for high-volume production of parts with complex geometries.

3D Printing Adaptability

In addition to traditional molding, ABS-CF20 can be adapted for additive manufacturing processes. This opens up possibilities for rapid prototyping and customization of interior parts, helping designers bring unique concepts to life quickly.

Design Flexibility and Innovation

Complex Geometries

ABS-CF20 enables the creation of intricate shapes without sacrificing structural integrity. Designers can push the boundaries of form while maintaining the strength and durability that automotive applications require.

Integrated Features

The material’s stability and toughness make it possible to integrate multiple functional elements into a single part, reducing assembly complexity and improving product reliability.

Enhanced User Experience

Every part of an automotive interior contributes to the overall user experience. ABS-CF20 allows for components that feel solid, operate quietly, and look premium. Passengers notice the difference when parts fit perfectly, resist wear, and maintain their original appearance.

Long-Term Performance in Real Conditions

Resistance to Wear

Automotive interiors are exposed to continuous friction and handling. ABS-CF20 resists surface wear, keeping panels and trims looking new even with frequent use.

Environmental Resilience

From cold winter mornings to hot summer afternoons, ABS-CF20 performs consistently. It resists the effects of temperature swings, UV exposure, and humidity changes.

Sustainability Considerations

While performance is essential, sustainability is also a growing concern. ABS-CF20 supports efforts to reduce environmental impact by contributing to lightweight designs that improve fuel efficiency. It can also be recycled through established ABS recycling processes, helping to minimize waste.

Conclusion: The Ideal Choice for Automotive Interiors

ABS-CF20 represents the next step in material innovation for automotive interiors. Its combination of enhanced toughness, lightweight design, dimensional stability, and aesthetic potential makes it an exceptional choice for manufacturers aiming to deliver quality and style.

If you want to get more information about ABS-CF10, you can visit our YouTube.

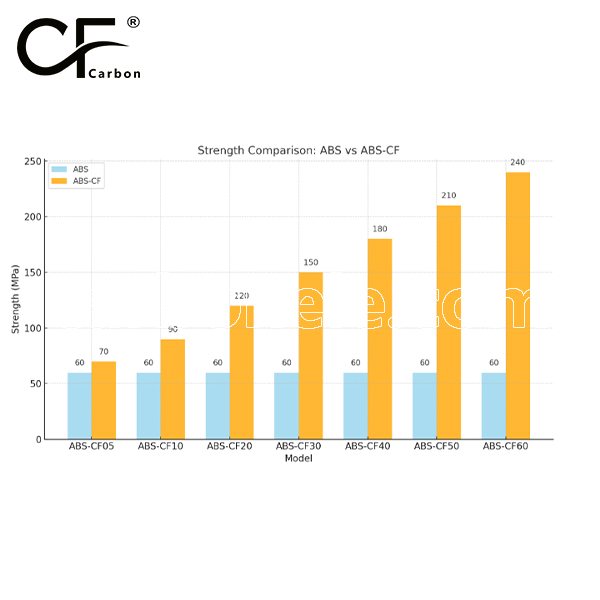

Strength between ABSand ABS-CF

ABS-CF (Carbon Fiber Reinforced ABS) offers a significant strength improvement over standard ABS. The addition of carbon fibers enhances ABS's tensile strength, impact resistance, and rigidity, making it more suitable for high-load and demanding environments. ABS-CF also exhibits better flexural strength and heat resistance compared to standard ABS, making it ideal for applications requiring higher strength and durability.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.