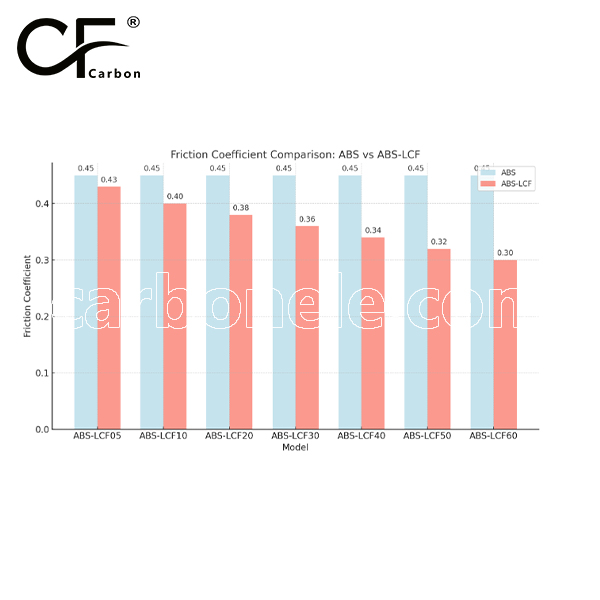

The friction coefficient of ABS is typically around 0.3 to 0.5, depending on surface finish and environmental factors. When low carbon fibers are added to form ABS-LCF, the friction coefficient generally decreases. The addition of low carbon fibers can reduce the friction coefficient to about 0.25 to 0.4, as the fibers help improve wear resistance and lower friction. The exact value can vary depending on the specific type of carbon fiber used, the proportion of carbon fiber in the composite, and the surface roughness of the materials involved.

ABS-LCF Composite – Lightweight Drone Frames

ABS-LCF composite delivers the ideal balance of strength, light weight, and durability for high-performance drone frames. Perfect for racing and professional drones, ABS-LCF improves stability, impact resistance, and flight efficiency while allowing creative frame designs. Discover why ABS-LCF is the next step in lightweight drone technology.

- Model number: ABS-LCF

- Matrix Resin: Acrylonitrile Butadiene Styrene (ABS)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

ABS-LCF Composite – Lightweight Drone Frames

Introduction to ABS -LCF Composite

ABS-LCF is a modern composite material that combines the reliable mechanical properties of ABS with the structural benefits of long carbon fiber reinforcement. It offers an exceptional strength-to-weight ratio, improved rigidity, and enhanced durability while maintaining the processability that designers and manufacturers expect from ABS. This makes ABS-LCF a preferred choice for applications where weight reduction and strength are equally critical.

When it comes to high-performance parts, such as drone frames, these properties directly contribute to better stability, increased maneuverability, and improved lifespan of the product. The combination of lightweight design and strong structural performance makes ABS-LCF ideal for modern engineering challenges.

Why ABS-LCF is Perfect for Lightweight Drone Frames

The aerospace and drone industry demands materials that are both light and strong. A lightweight frame ensures better flight efficiency, while a rigid structure improves control and reduces vibration. ABS-LCF meets these requirements by delivering a material that can withstand operational stress without adding unnecessary weight.

For drone frames, ABS-LCF provides excellent resistance to impact during landings or collisions, as well as stable performance in varying weather conditions. These qualities allow hobbyists, professionals, and industrial users to benefit from extended drone life and reliable performance in different environments.

Benefits of Using ABS-LCF for Drones

-

Lightweight design that enhances flight efficiency and reduces battery strain.

-

High stiffness for precise control and stable flight.

-

Impact resistance to withstand accidental drops and hard landings.

-

Weather resilience for outdoor and all-season usage.

-

Smooth surface finish that allows aerodynamic shaping and aesthetic appeal.

Example Application: Custom Racing Drone Frame

A racing drone requires a frame that is light enough to accelerate quickly yet strong enough to endure sharp turns, high-speed impacts, and competitive conditions. ABS-LCF offers the perfect balance for this scenario.

By using ABS-LCF in a racing drone frame, builders can achieve a significant performance boost without sacrificing durability. The composite’s rigidity keeps the drone stable during high-speed maneuvers, while its lightweight nature enables longer flight times. Additionally, its processability allows for complex frame designs that can integrate aerodynamic features directly into the structure.

Design Freedom with ABS -LCF

Drone designers often face limitations when working with weaker or heavier materials. ABS-LCF changes that equation by allowing more creative, functional, and lightweight designs. This means custom shapes, integrated mounting points, and streamlined profiles can be produced without compromising strength.

Other Potential Uses of ABS-LCF in Drones

While lightweight frames are a major application, ABS-LCF can also be used in other drone components, such as

-

Motor mounts that resist bending under load.

-

Protective housings for electronic components.

-

Landing gear that absorbs shock during landings.

-

Camera gimbals with low vibration for stable footage.

These additional uses highlight the versatility of ABS-LCF in supporting the entire structure and functionality of a drone.

Manufacturing Advantages of ABS-LCF

Beyond performance benefits, ABS-LCF offers manufacturing advantages. Its compatibility with common molding and forming processes makes it accessible for both small-scale and large-scale production. Manufacturers can produce consistent, high-quality parts without costly process changes.

Processing and Finishing

ABS-LCF parts can be easily machined, drilled, and finished for custom applications. This allows manufacturers to adapt drone frame designs to specific customer needs or performance requirements. The surface of ABS-LCF also accepts coatings and paints, giving additional opportunities for customization.

Sustainability Considerations

Lightweight materials like ABS-LCF contribute to energy efficiency, especially in battery-powered devices such as drones. Reduced weight can mean longer operational time and less frequent battery charging, which in turn can lower overall energy consumption. For commercial drone fleets, this translates to better operational efficiency and reduced environmental impact over time.

Conclusion: ABS-LCF for Next-Generation Drone Design

ABS-LCF has proven itself as a high-performance composite capable of meeting the demanding requirements of modern drone applications. By combining low weight with exceptional strength and durability, it enables the creation of drone frames that are both competitive and reliable.

For hobbyists, professionals, and manufacturers alike, ABS-LCF offers a solution that improves performance without adding complexity to the production process. Its adaptability, design freedom, and long-term durability make it a standout choice for the next generation of drone technology.

If you want to get more information about ABS-LCF60, you can visit our YouTube.

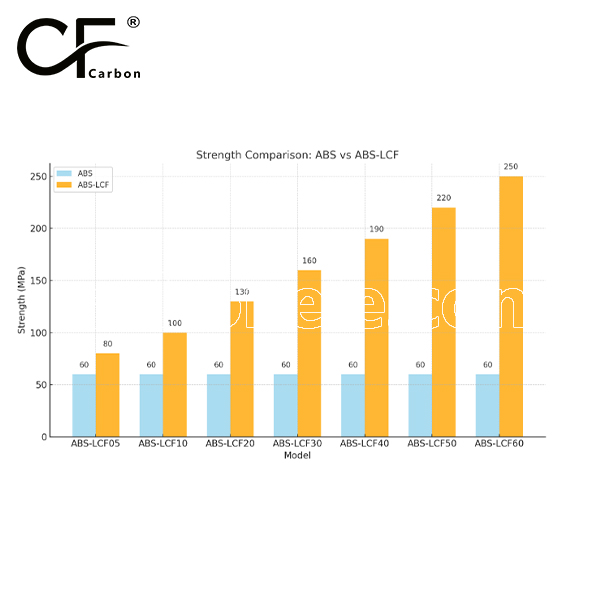

Strength between ABS and ABS-LCF

ABS-LCF (Low Carbon Fiber Reinforced ABS) offers a noticeable strength improvement over standard ABS. The addition of low carbon fiber content enhances ABS's tensile strength, impact resistance, and rigidity, making it more suitable for moderate-load and demanding environments. ABS-LCF also provides better flexural strength and heat resistance compared to standard ABS, making it ideal for applications requiring improved strength and durability without compromising processability.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.