CF-RTP Thermoplastic Compounds PA6 CF40 Particles

1: Tensile strength reaches 285 MPa

2: Heat deflection temperature up to 215°C

3: Thermal expansion coefficient 2.1×10⁻⁵/°C

4: Wear rate reduced by eighty-five percent

5: Water absorption below one point five percent

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free samples: ≤10kg

- MOQ: 100kg

- Port: Xiamen

- Model: PA6-CF-BCA4

- Fillers: SCF

I. PA6 CF40 Overview

PA6 CF40 Particles are high-performance composite materials consisting of polyamide 6 matrix reinforced with 40% carbon fiber. This composition delivers an optimal balance of mechanical strength, thermal stability, and lightweight properties, making it an ideal material for demanding engineering applications.

II. PA6 CF40 Particles Key Properties

1. Excellent Mechanical Strength

Tensile strength reaches 285 MPa, flexural strength 380 MPa, significantly outperforming unreinforced materials, suitable for high-load structural components.

2. Outstanding Heat Resistance

Heat deflection temperature (HDT) up to 215°C (1.82 MPa), maintaining dimensional stability and mechanical properties in high-temperature environments.

3. Low Thermal Expansion Coefficient

Coefficient of thermal expansion as low as 2.1×10⁻⁵/°C, ensuring dimensional stability of precision components during temperature fluctuations.

4. Good Wear Resistance

Wear rate reduced by 85% compared to unreinforced PA6, particularly suitable for moving parts and wear-resistant applications.

5. Superior Dimensional Stability

Water absorption below 1.5%, minimal dimensional change, ideal for manufacturing high-precision engineering parts.

III. Material Primary Applications

This material is widely used in automotive engine components, aerospace structural parts, industrial gears and bearings, electronic insulation components, and sports equipment. PA6 CF40 Particles are particularly suitable for applications requiring lightweight, high strength, and high heat resistance.

IV. PA6 CF40 Particles Application in Automotive Engine Brackets

A German automotive manufacturer adopted PA6 CF40 Particles for engine brackets in a new electric vehicle platform. The component needed to withstand 2000N static load and 10⁷ fatigue cycles, while operating within a temperature range of -40°C to 120°C. By using CF-RTP Thermoplastic Compounds, the part weight was reduced by 45% compared to aluminum alloy, production costs decreased by 30%, and it passed rigorous vibration and durability tests. This application demonstrates the excellent performance of PA6 CF40 Particles in automotive structural components.

For detailed data sheets of PA6 CF40 Particles, technical clarifications or quotations, please contact our engineering team. It should be noted that the performance of CF-RTP Thermoplastic Compounds may vary significantly depending on matrix resin type, carbon fiber content and manufacturing process. It is recommended to evaluate the actual performance of CF-RTP Thermoplastic Compounds through comparative testing based on specific application requirements. CF-RTP Thermoplastic Compounds from different suppliers may differ in performance emphasis and application characteristics.

CFRTP VERSUS CFRP

1. CFRTP demonstrates significantly faster processing time (5 minutes) compared to CFRP (45 minutes), representing a 90% reduction in manufacturing duration. 2. In terms of recyclability, CFRTP outperforms CFRP by a large margin, scoring 9 on a 1-10 scale versus CFRP's score of 2. 3. CFRTP exhibits superior impact resistance (90 kJ/m²) compared to CFRP (65 kJ/m²), showing approximately 38% better performance in this category. 4. While CFRP has higher temperature resistance (220°C) than CFRTP (180°C), both materials maintain adequate thermal performance for most applications. 5. CFRTP offers greater design flexibility (rating of 90) compared to CFRP (rating of 60), providing more versatility in manufacturing and application scenarios.

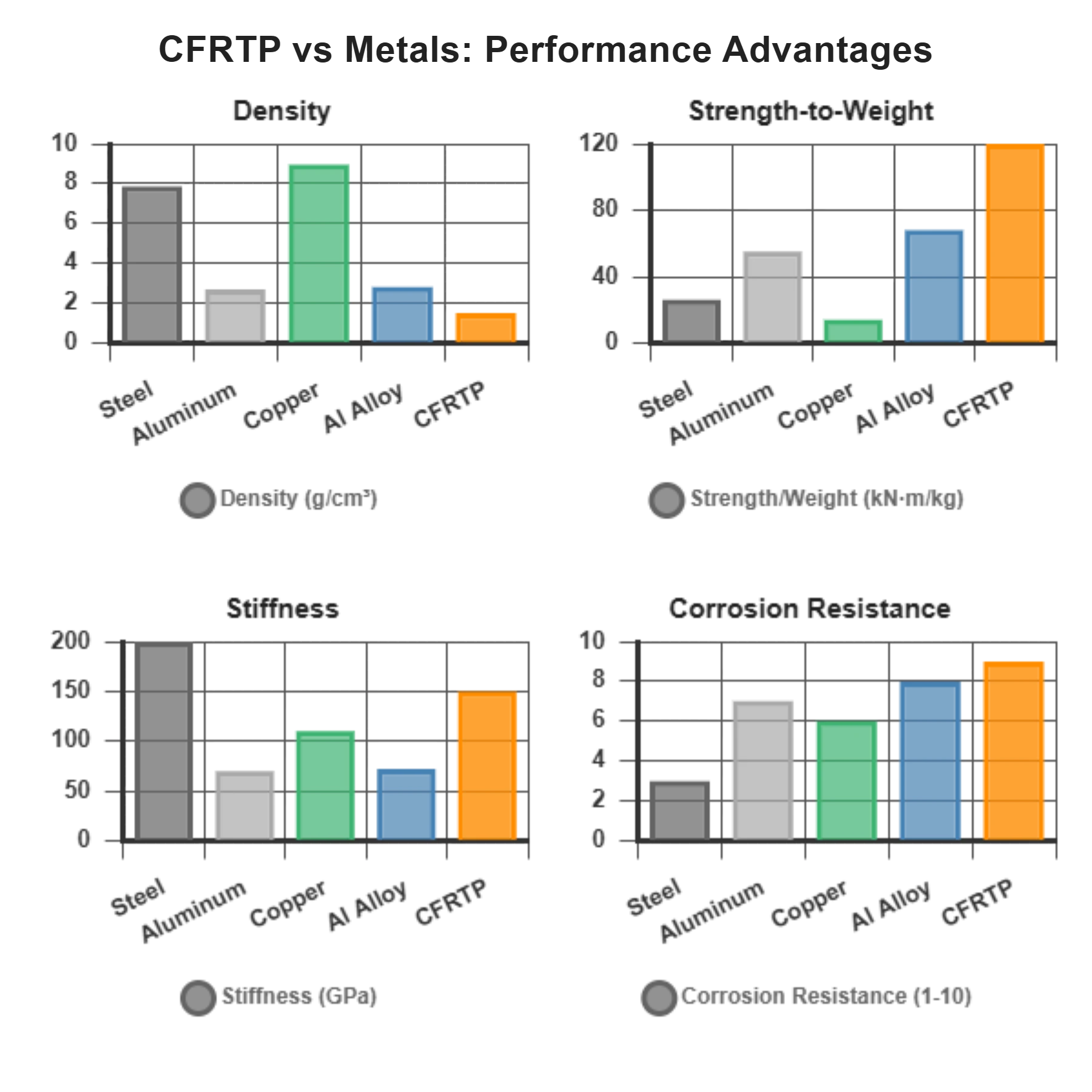

CFRTP VS. METALS

1. CFRTP exhibits the lowest density (1.50 g/cm³) among all compared materials, significantly outperforming traditional metals like steel (7.85 g/cm³) and copper (8.96 g/cm³), and even surpassing aluminum (2.70 g/cm³) and aluminum alloy (2.80 g/cm³). 2. In terms of strength-to-weight ratio, CFRTP demonstrates superior performance at 120 kN·m/kg, more than doubling the ratio of aluminum alloy (68 kN·m/kg) and far exceeding steel (26 kN·m/kg) and copper (14 kN·m/kg). 3. While steel shows the highest stiffness (200 GPa), CFRTP (150 GPa) outperforms aluminum (70 GPa), aluminum alloy (72 GPa), and copper (110 GPa), offering a favorable balance of rigidity and lightweight properties. 4. CFRTP achieves the highest corrosion resistance rating (9 on a 1-10 scale), surpassing all other materials including aluminum alloy (8), aluminum (7), copper (6), and steel (3), making it ideal for corrosive environments.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.