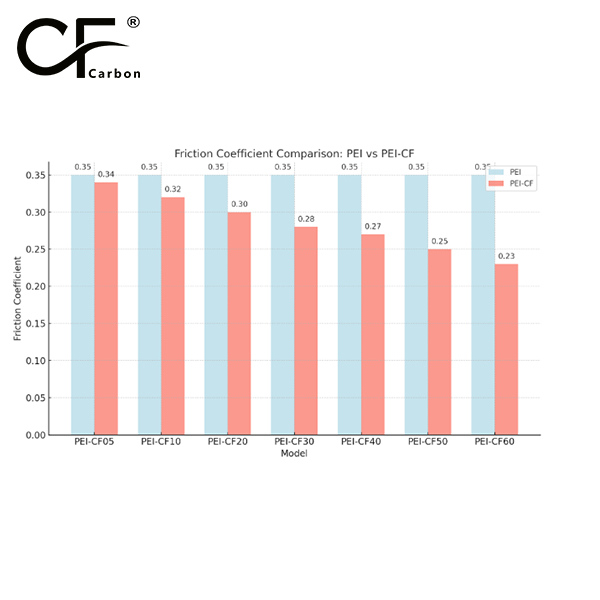

The friction coefficient of pure PEI typically ranges between 0.3 and 0.4, depending on the specific surface and conditions of use. When carbon fiber is added to create PEI-CF, the friction coefficient is generally lower due to the increased wear resistance and lubrication properties provided by the carbon fibers. For PEI-CF, the coefficient of friction typically ranges from 0.2 to 0.3, depending on the carbon fiber content and surface conditions.The addition of carbon fibers reduces friction, improves wear resistance, and enhances the material’s performance in high stress, abrasive environments.

Heat-Resistant PEI-CF20 Industrial Solution

Heat-resistant PEI-CF20 carbon fiber reinforced polymer for aerospace, automotive & industrial applications. Superior thermal stability, mechanical strength & chemical resistance

- Model number: PEI-CF-BCA6

- Matrix Resin: Polyethyleneimine (PEI)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Heat-Resistant PEI-CF20 Industrial Solution

Introduction to PEI-CF20 for Demanding Industrial Applications

Industries that operate in high-temperature and high-stress environments require materials capable of delivering long-term stability without compromising on performance. PEI-CF20 stands at the forefront of these requirements, offering a balance of heat resistance, mechanical strength, and dimensional stability that has earned it a place in advanced engineering projects across multiple sectors.

It is a polymer matrix reinforced with carbon fibers, delivering enhanced rigidity while maintaining the inherent thermal and chemical resistance of polyetherimide. This synergy allows it to excel in environments where standard polymers might fail. The combination of structural reinforcement and heat tolerance makes it an ideal solution for precision components that must endure prolonged exposure to challenging conditions.

The Unique Advantages of PEI-CF20 in Industrial Environments

Exceptional Heat Resistance

The defining feature of PEI-CF20 is its ability to retain mechanical properties under high-temperature conditions. This is a crucial advantage for industries where operational heat levels challenge the limits of other materials. The integration of carbon fibers into the polymer matrix further stabilizes the material’s structure, reducing thermal deformation over prolonged exposure.

Mechanical Strength with Reduced Weight

Industrial components often face the challenge of balancing strength with weight. PEI-CF20 addresses this by offering high tensile and flexural strength while maintaining a lower weight compared to many metal alternatives. This combination contributes to more efficient machinery designs, reduced energy consumption, and improved handling during manufacturing and assembly.

Dimensional Stability for Precision Applications

Many advanced manufacturing processes demand parts that maintain exact dimensions even after prolonged use. PEI-CF20’s dimensional stability ensures that tight tolerances are preserved, minimizing the need for frequent recalibration or part replacement.

Why Industries Choose PEI-CF20 Over Traditional Materials

Resistance to Harsh Chemicals

PEI-CF20 maintains structural integrity in the presence of aggressive chemicals, oils, and industrial fluids. This resistance ensures that components continue to perform reliably even in environments with constant exposure to corrosive agents.

Extended Service Life

The combination of mechanical stability, heat resistance, and chemical durability translates into a longer operational lifespan for parts made with PEI-CF20. This reduces maintenance costs and downtime, providing a significant advantage for large-scale operations.

Compatibility with Advanced Manufacturing Techniques

PEI-CF20 can be processed using both conventional and precision manufacturing methods, from injection molding to CNC machining. This adaptability allows engineers to produce both mass-market components and custom designs with equal efficiency.

Application Example: PEI-CF20 in Aerospace Electrical Housings

One of the most effective demonstrations of PEI-CF20’s capabilities can be seen in aerospace electrical housings. These components are essential for protecting sensitive electronic systems from heat, vibration, and chemical exposure during flight operations.

Benefits in Aerospace

In aerospace applications, every gram matters, and the combination of lightweight strength and heat tolerance offered by PEI-CF20 becomes invaluable. Electrical housings made from this material protect internal systems while withstanding the extreme temperatures encountered during high-altitude operation.

Enhanced Reliability

The durability of PEI-CF20 ensures that electrical housings can resist deformation under continuous stress, maintaining their protective role for extended service intervals. This reliability supports mission safety and operational efficiency in both commercial and defense aerospace sectors.

Manufacturing with PEI-CF20

Injection Molding Precision

PEI-CF20 performs exceptionally well in injection molding, allowing the creation of complex shapes with fine detail. This is critical when producing components for intricate assemblies where fit and function must be exact.

Machining Capabilities

Beyond molding, PEI-CF20 is also well-suited to machining processes, enabling custom prototypes and small production runs to meet unique project requirements. This dual capability supports innovation while maintaining consistency in large-scale production.

Surface Finish and Aesthetic Appeal

While primarily valued for performance, PEI-CF20 also delivers a clean, consistent surface finish. This is especially important for visible industrial components, where a professional appearance complements high technical performance.

Heat-Resistant Performance in Continuous Operation

The real test for any industrial material lies in its ability to perform under operational stress without degradation. PEI-CF20 demonstrates remarkable consistency under sustained heat exposure, maintaining its strength and shape across thousands of operational cycles. This resilience makes it a material of choice for sectors where downtime is costly and reliability is paramount.

Chemical and Environmental Resistance

Industries operating in chemically aggressive or moisture-rich environments demand materials that resist breakdown over time. PEI-CF20 provides this assurance, with resistance to a wide range of industrial chemicals and the ability to withstand humid or corrosive atmospheres without compromise.

Sustainability and Long-Term Value

The durability and longevity of PEI-CF20 not only enhance operational efficiency but also contribute to sustainability by reducing the frequency of part replacement. This long-term performance reduces waste and supports environmentally conscious manufacturing strategies.

The Future Potential of PEI-CF20

As industries evolve toward higher efficiency, lower weight, and greater durability, PEI-CF20 is positioned to play an increasingly important role. Ongoing research continues to uncover new applications in fields ranging from high-performance automotive components to advanced renewable energy systems.

Conclusion

PEI-CF20 stands as a proven solution for industrial challenges where heat, strength, and chemical resistance are non-negotiable. From aerospace to automotive, from electronics to heavy machinery, it delivers the performance and reliability that engineers and manufacturers require. As industries push the boundaries of what is possible, it will remain at the forefront, enabling innovation and ensuring operational success.

If you want to get more information about PEI-CF60, you can visit our YouTube.

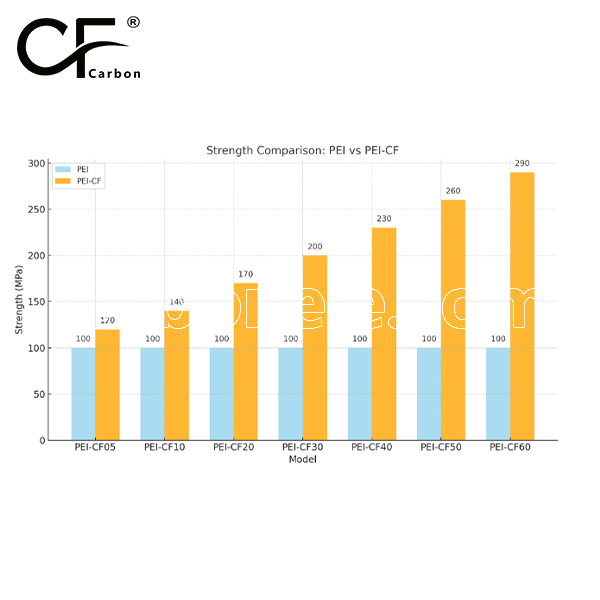

Strength between PEI and PEI-CF

PEI offers strong mechanical properties, excellent thermal stability, and chemical resistance for moderate duty applications. PEI-CF, with added carbon fiber, significantly enhances stiffness, wear resistance, and mechanical strength, making it ideal for high performance environments that require superior strength and durability under stress.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.