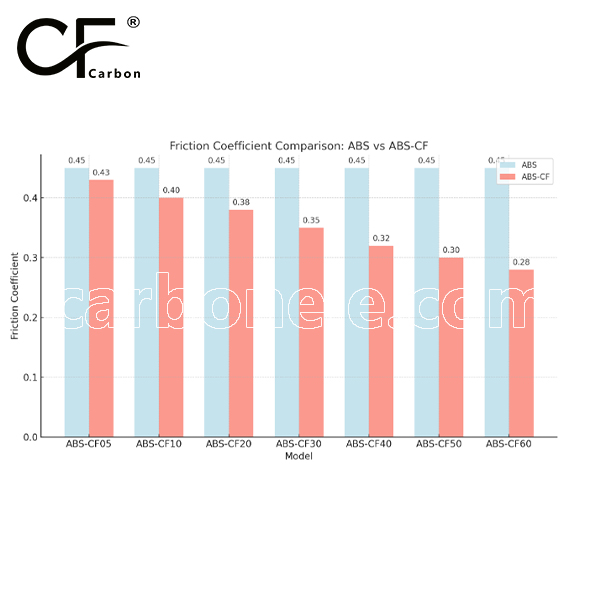

The friction coefficient of ABS is typically around 0.3 to 0.5, depending on surface finish and environmental factors. When carbon fibers are added to form ABS-CF, the friction coefficient generally decreases. The addition of carbon fibers can reduce the friction coefficient to about 0.2 to 0.4, as the fibers act as lubricants, improving wear resistance and lowering friction. The exact value can vary depending on the specific type of carbon fiber used, the proportion of carbon fiber in the composite, and the surface roughness of the materials involved.

High-performance ABS-CF10 Material for Electronics Enclosures

High-performance ABS-CF10 carbon fiber composite material for premium electronics enclosures. Offers superior strength, lightweight design & aesthetic appeal. Ideal for routers, handheld devices & industrial housings.

- Model number: ABS-CF-BCA1

- Matrix Resin: Acrylonitrile Butadiene Styrene (ABS)

- Reinforcing Filler: Carbon fiber

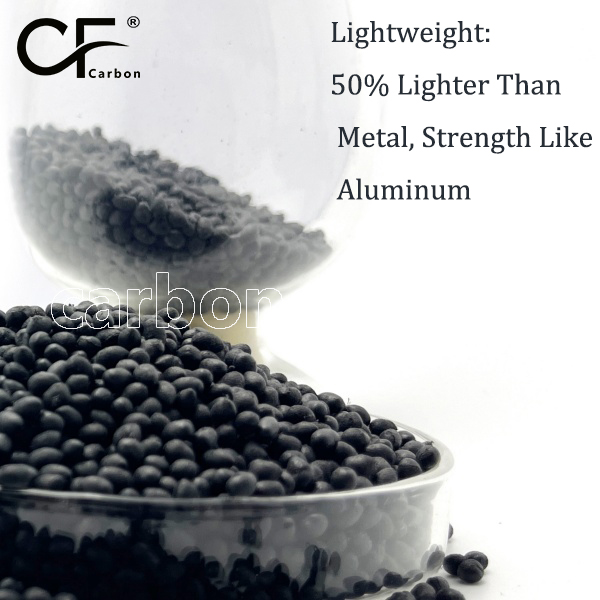

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

High-performance ABS-CF10 Material for Electronics Enclosures

Introduction to ABS-CF10

When manufacturers, designers, and innovators look for a material that balances strength, lightweight properties, and design flexibility, it stands out as a superior option.

This advanced compound combines the trusted qualities of ABS with the reinforcement of carbon fiber, creating a versatile thermoplastic that performs exceptionally well in both functional and aesthetic applications.

From electronic devices to industrial components, it is increasingly becoming the material of choice for high-performance demands.

In this detailed guide, we will explore everything you need to know about it, with a special focus on its application in electronics enclosures. You will discover why it is favored by engineers, what makes it unique, and how it offers long-term benefits for businesses that rely on material innovation.

Understanding the Nature of ABS-CF10

The Foundation of ABS-CF10

At its core, it is a blend of acrylonitrile butadiene styrene (ABS) combined with carbon fiber reinforcement. This engineered composition delivers enhanced rigidity, dimensional stability, and surface finish.

Unlike traditional ABS, which is already valued for its durability and ease of processing, it elevates performance to a new level by integrating carbon reinforcement into the matrix.

Why Engineers Prefer ABS-CF10

Engineers choose ABS-CF10 not just for its physical strength but also for its ability to deliver consistent results in demanding environments.

It withstands mechanical stress, offers reduced warpage during molding, and ensures lightweight construction without compromising toughness.

Its predictable behavior under design constraints makes it a dependable solution for both prototyping and large-scale manufacturing.

Key Benefits of ABS-CF10

Durability and Structural Integrity

One of the primary reasons ABS-CF10 is highly regarded is its superior durability. With enhanced resistance to impact and cracking, it provides a longer service life for products exposed to mechanical or thermal challenges.

This durability is particularly vital in electronics enclosures, where protection against external forces is crucial.

Lightweight and Efficient

While metals can provide strength, they often increase the overall weight of a component. It bridges this gap by offering a strong yet lightweight solution. The reduced weight contributes to lower shipping costs, easier handling, and more ergonomic product designs.

Excellent Surface Quality

Another advantage of ABS-CF10 is its smooth surface finish, which allows for excellent aesthetic appeal. Manufacturers producing consumer electronics benefit from this feature since it supports paintability, texturing, and branding applications.

Dimensional Stability

Consistency is critical in industrial manufacturing. It maintains precise dimensions throughout production, ensuring that enclosures and components fit seamlessly into assemblies.

This stability reduces post-processing requirements and minimizes production errors.

Application Example: Electronics Enclosures

Why ABS-CF10 is Ideal for Electronics Enclosures

In the field of consumer and industrial electronics, enclosures serve as both protective shells and visual representations of product quality.

It is particularly effective in this role because it combines strength with lightweight properties, ensuring devices remain portable yet well-protected.

Its resistance to stress cracking and dimensional deformation means that even under daily use, enclosures maintain their integrity and reliability.

Case Study: Portable Device Housing

Consider a company developing portable diagnostic equipment for medical applications. Traditional ABS could offer durability, but frequent transport, handling, and exposure to varying conditions demand more resilience.

By choosing ABS-CF10, the manufacturer ensures that the housing resists impact, maintains its form, and provides a premium tactile finish for users. The result is a product that inspires confidence in both its performance and quality.

Long-term Value for Electronics Manufacturers

By adopting ABS-CF10 for enclosures, manufacturers can achieve:

Reduced failure rates due to improved impact resistance.

Enhanced brand reputation through superior product aesthetics.

Cost savings in shipping and assembly from lighter-weight components.

Consistent performance that aligns with evolving consumer expectations.

Design Flexibility with ABS-CF10

Freedom in Shape and Form

Designers benefit from the flexibility of ABS-CF10, which can be molded into complex geometries without compromising its structural properties.

This opens opportunities for innovative designs in electronic enclosures, from sleek handheld devices to rugged industrial cases.

Compatibility with Modern Manufacturing Methods

Whether through injection molding, additive manufacturing, or hybrid processes, ABS-CF10 adapts seamlessly.

Its versatility makes it a material that supports modern design approaches while ensuring high repeatability in production.

Industries That Benefit from ABS-CF10

Electronics and Consumer Devices

The electronics industry relies heavily on protective materials that balance strength and appearance.

ABS-CF10 is widely used in computer housings, gaming consoles, handheld devices, and other electronic systems that require lightweight yet strong shells.

Automotive and Transport Applications

Beyond electronics, the automotive sector utilizes ABS-CF10 for components that demand both resilience and reduced weight. Dashboards, panels, and trim parts can be manufactured with greater efficiency using this advanced material.

Industrial Equipment

Industrial enclosures, protective casings, and machine housings benefit from ABS-CF10 due to its stability and resistance to demanding operational conditions.

The Business Advantage of Choosing ABS-CF10

Efficiency in Production

Because of its predictable molding behavior, ABS-CF10 reduces production delays and waste. This efficiency leads to better resource management and improved return on investment for manufacturers.

Enhancing Brand Perception

End-users increasingly value products that are not only functional but also feel premium. The surface finish and durability of ABS-CF10 add a professional touch to products, improving customer satisfaction and loyalty.

Long-term Sustainability

Lightweight materials like ABS-CF10 contribute to more sustainable manufacturing by reducing transportation emissions and energy consumption. Companies focused on greener production strategies find this material aligns with their environmental goals.

Future of ABS-CF10 in Material Innovation

The demand for materials that combine performance with design flexibility is set to grow. ABS-CF10 sits at the intersection of these requirements, offering a future-ready solution for industries aiming to innovate responsibly.

With the rise of portable electronics, smart devices, and high-performance industrial products, the role of ABS-CF10 will only expand.

Conclusion

ABS-CF10 is not just a material; it is a solution that empowers businesses to innovate while maintaining reliability and efficiency.

Its combination of durability, lightweight properties, and aesthetic appeal makes it especially valuable for electronics enclosures, where functionality and design must coexist seamlessly.

For manufacturers seeking a competitive edge, adopting ABS-CF10 can mean stronger products, higher customer satisfaction, and better long-term results.

As industries continue to demand advanced material performance, ABS-CF10 stands ready to meet and exceed those expectations.

If you want to get more information about ABS-CF10, you can visit our YouTube.

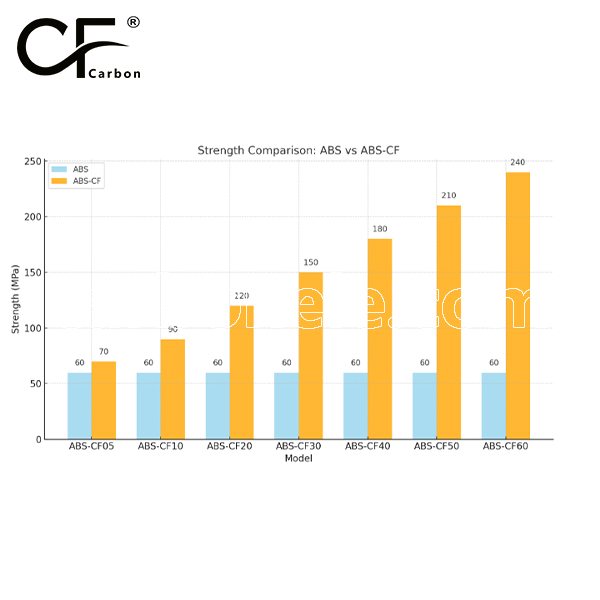

Strength between ABSand ABS-CF

ABS-CF (Carbon Fiber Reinforced ABS) offers a significant strength improvement over standard ABS. The addition of carbon fibers enhances ABS's tensile strength, impact resistance, and rigidity, making it more suitable for high-load and demanding environments. ABS-CF also exhibits better flexural strength and heat resistance compared to standard ABS, making it ideal for applications requiring higher strength and durability.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.