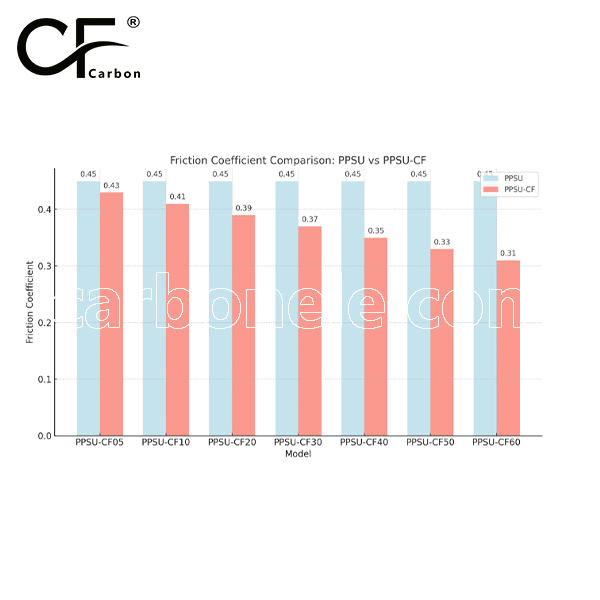

PPSU-CF, reinforced with carbon fiber, typically offers a lower friction coefficient compared to unreinforced PPSU. The addition of carbon fiber reduces surface roughness and increases rigidity, leading to better wear resistance and lower friction. The friction coefficient of PPSU-CF generally ranges from 0.2 to 0.3, compared to 0.3 to 0.4 for pure PPSU. This makes PPSU-CF ideal for high performance applications requiring low friction and enhanced durability.

High-Strength PPSU-CF for Medical Use

Discover PPSU-CF for medical use—a high-strength, heat-resistant material ideal for sterilizable surgical tools, diagnostic housings, and reusable instruments.

- Model number: PPSU-CF-BCA

- Matrix Resin: Polyphenylene sulfone resins (PPSU)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

High-Strength PPSU-CF for Medical Use

When medical performance demands exceed the limits of ordinary plastics, PPSU-CF (carbon fiber reinforced polyphenylsulfone) steps in as a next-generation solution. Designed for durability, high thermal resistance, and long-term dimensional stability, PPSU-CF performs reliably in challenging healthcare environments.

Why PPSU-CF Excels in Medical Applications

Medical-grade plastics are expected to endure repeated sterilization cycles, impact stress, and exposure to aggressive cleaning agents. PPSU-CF meets these expectations and goes further—its reinforced carbon fiber structure adds stiffness without compromising toughness, making it a go-to material for high-performance medical tools and components.

Built for Repeated Sterilization

Unlike conventional thermoplastics that degrade under frequent sterilization, PPSU-CF maintains mechanical integrity in the face of repeated autoclaving, gamma exposure, or chemical sanitization. This makes it ideal for use in reusable surgical instruments, endoscopic handles, and sterilizable trays.

For example, in laparoscopic surgery, precision tools require handles that are not only lightweight and ergonomic but also capable of withstanding dozens of high-temperature sterilization cycles. PPSU-CF maintains shape and performance under these conditions, reducing replacement frequency and improving equipment longevity.

Exceptional Dimensional Stability in Harsh Conditions

Medical components often face unpredictable environments—from operating room temperatures to on-the-go emergency care. PPSU-CF resists thermal expansion and mechanical deformation, ensuring reliable fit and performance in precision assemblies. This is particularly important in handheld diagnostic devices, where internal alignment affects accuracy.

A real-world case involves a surgical retractor system with moving components. Traditional plastic parts warped over time, affecting function. After switching to PPSU-CF, the issue was eliminated—the carbon fiber reinforcement provided long-term dimensional control without sacrificing weight.

Chemical Resistance That Supports Hospital Protocols

Cleaning chemicals used in medical settings are often aggressive and continuous. PPSU-CF resists degradation from alcohols, disinfectants, and enzymatic solutions, ensuring that surface quality, strength, and performance remain unchanged.

This is crucial in hospital-grade dental devices, where harsh cleaning is part of the daily routine. Standard plastics discolor or crack, while PPSU-CF preserves appearance and structure, supporting safe, long-term use.

Key Benefits of PPSU-CF in Medical Manufacturing

Lightweight Yet Stiff

The addition of carbon fiber gives PPSU-CF a unique advantage—it is light enough for handheld devices yet stiff enough to replace metal parts in many cases. This balance makes it ideal for instrument housings and structural frames.

Excellent Impact Resistance

In fast-paced medical environments, tools get dropped. PPSU-CF doesn’t shatter under stress. It absorbs impact without fracture, ensuring safer and longer-lasting parts in daily use.

Machinable and Moldable

Whether for injection molding or CNC machining, PPSU-CF is easy to process into complex geometries. This enables manufacturers to create intricate, customized components that meet both functional and aesthetic medical demands.

Example Application – Surgical Tool Handle

Consider a reusable surgical grasper that requires a handle with ergonomic comfort, minimal flex, and resistance to both heat and chemical exposure. Traditional plastics softened after repeated use, creating reliability concerns. PPSU-CF offered the solution:

-

Maintained grip shape over multiple sterilization cycles

-

Withstood impact without cracking during operation

-

Eliminated need for metal reinforcement, reducing overall weight

The outcome? A cost-effective, high-performance handle that meets regulatory expectations and end-user satisfaction.

Why Medical Manufacturers Choose PPSU-CF

Medical equipment developers choose PPSU-CF not just for its technical properties but also for its role in improving patient outcomes and reducing equipment downtime. The material’s performance consistency means fewer product failures and fewer recalls—essential in a tightly regulated industry.

For OEMs (original equipment manufacturers), PPSU-CF helps streamline production and meet industry certifications. Its adaptability across sterilization methods supports global deployment, while its durability lowers lifecycle cost.

Unlock New Possibilities with PPSU-CF

Whether you’re designing precision components for surgical use or durable housings for diagnostics, PPSU-CF empowers innovation. It offers the unique combination of thermal endurance, chemical resistance, and mechanical strength that healthcare applications demand.

In a world where material performance can define safety and success, PPSU-CF delivers not only strength but also trust.

If you want to get more information, you can visit our YouTube.

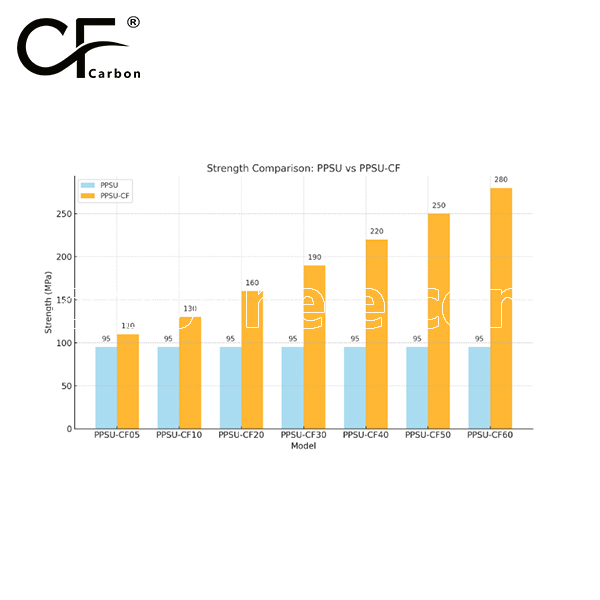

Strength between PPSU and PPSU-CF

PPSU-CF offers significantly higher strength than unreinforced PPSU due to the addition of carbon fiber. This reinforcement boosts both tensile and flexural strength, making PPSU-CF ideal for applications requiring enhanced mechanical performance and durability.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.