TPU-CF10 is a thermoplastic polyurethane (TPU) reinforced with 10% carbon fiber, combining the flexibility of TPU with the high strength and wear resistance of carbon fiber. It offers higher tensile strength, rigidity, and wear resistance, making it suitable for high-load and high-wear applications such as automotive seals and industrial components.

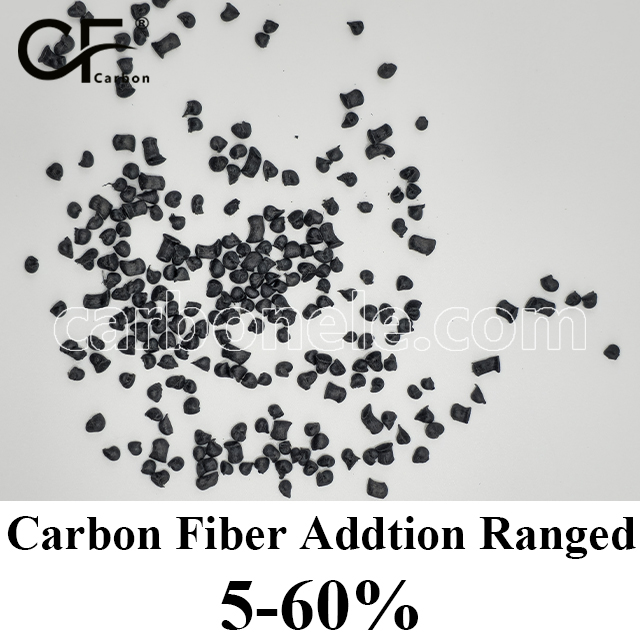

Injection molded carbon fiber filled TPU-CF10

- Model number: TPU-CF-BCA1

- Matrix Resin: Thermoplastic polyurethane (TPU)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

TPU-CF10 | 10% Carbon Fiber Reinforced Thermoplastic Polyurethane

TPU-CF10 is a reinforced thermoplastic elastomer that combines the inherent flexibility, abrasion resistance, and chemical durability of Thermoplastic Polyurethane (TPU) with 10% short carbon fiber reinforcement. This elevated fiber content brings a notable increase in stiffness, dimensional stability, and load-bearing performance—while preserving TPU’s hallmark elasticity and resilience under repeated stress.

With the right balance of toughness and flexibility, TPU-CF10 is ideal for applications that operate in dynamic, high friction, and mechanically demanding environments. Whether it’s vibration-dampening mounts, wear-resistant bushings, or flexible protective structures, TPU-CF10 enables reliable, long-lasting performance across a wide range of industries.

Key Advantages of TPU-CF10

Mechanical Strength

Carbon Fiber Content: 10% (Short carbon fiber)

Tensile Strength: ≥ 50 MPa

Elongation at Break: ≥ 150%

Shore Hardness: ~88A

→ Delivers enhanced stiffness, shape retention, and surface durability while maintaining good flexibility.

Thermal Performance

Heat Deflection Temperature (HDT): ~90°C

Continuous Use Temperature: Up to 75°C

→ Offers thermal endurance for moderate heat exposure, such as engine surroundings or industrial enclosures.

Environmental & Chemical Resistance

Moisture Absorption: Low – ensures mechanical stability and dimensional control in humid or submerged settings

Chemical Resistance: Excellent – resistant to oils, fuels, greases, and a broad range of industrial solvents

→ Withstands aggressive conditions without material degradation or softening.

Processing Characteristics

Molding Methods: Injection molding, extrusion, 3D filament extrusion

Surface Finish: Matte or slightly textured depending on fiber orientation and process parameters

Tooling Requirements: Compatible with standard steel molds; optimized for uniform fiber dispersion with moderate flow tuning

Target Applications for TPU-CF10

Automotive

Engine-adjacent brackets, NVH dampening components, flexible couplings

→ Supports load and flex requirements near high heat and high vibration zones.

Industrial & Automation Equipment

Bump stops, protective bellows, semi rigid guide supports

→ Offers controlled deflection and high wear resistance under cyclic loads.

Robotics & Actuation Systems

Cable management arms, flexible gripper elements, articulated joints

→ Balances precise movement with fatigue resistance and toughness.

Consumer & Sports Goods

Protective frame elements, outer shells, flexible impact zones

→ Delivers long-lasting comfort and resistance to daily mechanical stress and impact.

Performance Summary Table

| Property | Value / Description |

|---|---|

| Carbon Fiber Content | 10% (Short Carbon Fiber) |

| Tensile Strength | ≥ 50 MPa |

| Elongation at Break | ≥ 150% |

| Shore Hardness | ~88A |

| Heat Deflection Temp. | Approx. 90°C |

| Long Term Service Temp. | Up to 75°C |

| Water Absorption | Low – maintains strength and shape |

| Chemical Resistance | Excellent – fuels, oils, greases, solvents |

| Wear Resistance | Very High – suitable for repeated abrasion |

| Processing Methods | Injection molding, extrusion, 3D printing |

| Surface Finish | Matte or semi-textured – slight fiber visibility |

| Dimensional Stability | Enhanced – reliable under mechanical stress |

If you want to get more information aboutTPU-CF10, you can vist our Youtube.

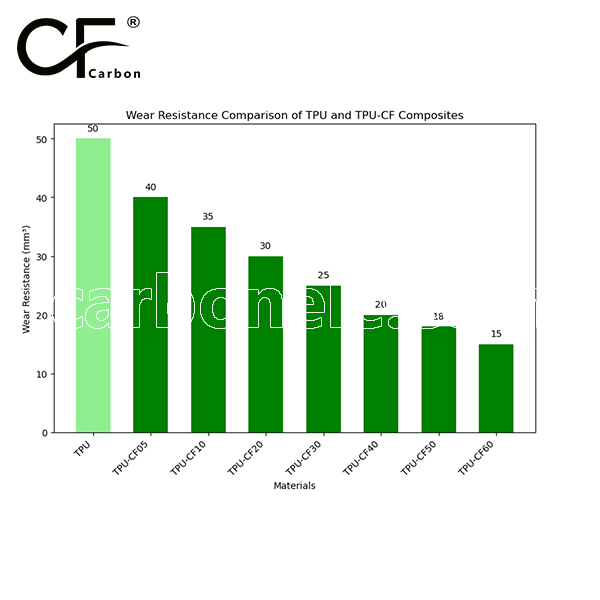

Friction coefficient of PA12-LCF

The friction coefficient of TPU is typically between 0.3 and 0.5, while TPU-CF, with added carbon fiber, lowers the friction coefficient to between 0.2 and 0.4. The smaller the value, the better the wear resistance. Therefore, TPU-CF generally offers better wear resistance than pure TPU, especially under high-load conditions.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

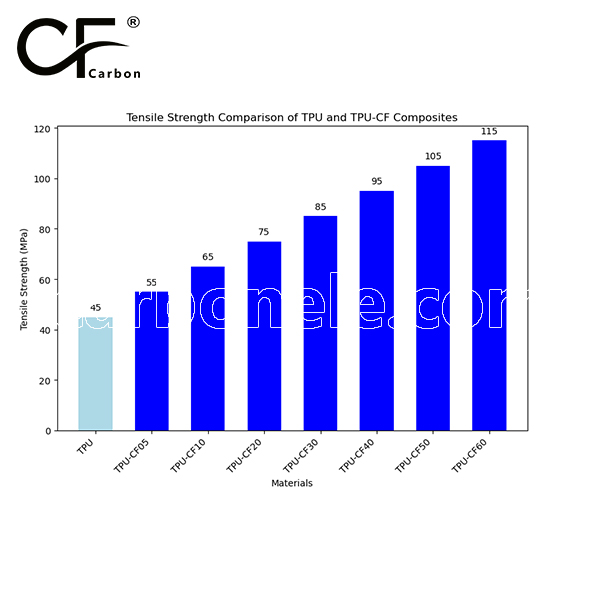

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.