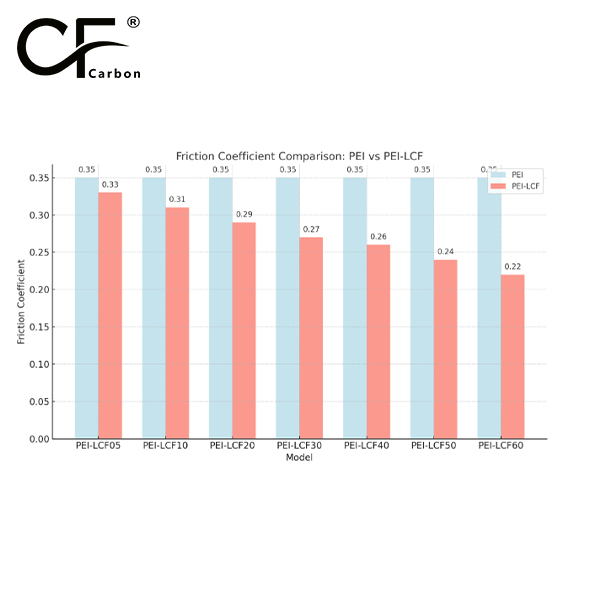

The friction coefficient of pure PEI typically ranges between 0.3 and 0.4, depending on the specific surface and conditions of use. When low carbon fiber (LCF) is added to create PEI-LCF, the friction coefficient generally decreases due to the enhanced wear resistance and lubrication properties provided by the carbon fibers. For PEI-LCF, the coefficient of friction typically ranges from 0.25 to 0.35, depending on the carbon fiber content and surface conditions. The addition of low carbon fibers reduces friction, improves wear resistance, and enhances the material’s performance in moderate stress and abrasive environments.

Innovative PEI-LCF10 for Optical Lens Barrels

PEI-LCF10 high-performance carbon fiber reinforced PEI composite. Ideal for precision optical lens barrels, offering exceptional dimensional stability, stiffness, and lightweight properties.

- Model number: PEI-LCF-BCA1

- Matrix Resin: Polyethyleneimine (PEI)

- Reinforcing Filler: Long carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Innovative PEI-LCF10 for Optical Lens Barrels

In the meticulous world of high-precision optics, where the clarity of a single image can dictate the success of a scientific discovery, a medical diagnosis, or a cinematic masterpiece, the pursuit of perfection is relentless.

This pursuit extends far beyond the glass elements themselves to the critical structures that hold them.

The barrel of an optical lens—the cylindrical housing that aligns and protects the delicate arrangement of glass—is a masterpiece of engineering in its own right.

Its performance is paramount, demanding a material that embodies an almost paradoxical set of properties: it must be incredibly rigid yet lightweight, stable across varying conditions, and manufactured to micron-level precision.

For decades, the choice has oscillated between metals, which provide strength but add significant weight and thermal management challenges, and standard polymers, which are light but often lack the necessary stability and strength.

This longstanding compromise is now rendered obsolete by a new class of advanced materials.

A groundbreaking polyetherimide composite, reinforced with a specific formulation of carbon fiber, has emerged to redefine the standards of optical component design.

This material, known as PEI-LCF10, represents a significant leap forward, offering a synergistic combination of properties that make it the ideal candidate for manufacturing the next generation of high-performance optical lens barrels.

The adoption of PEI-LCF10 is not merely a substitution of one material for another; it is an enabling technology that allows optical engineers to overcome traditional limitations and achieve new heights of performance and reliability.

The fundamental superiority of PEI-LCF10 stems from its sophisticated composite architecture.

The base resin is a high-performance polyetherimide, a polymer renowned for its inherent thermal resilience, exceptional mechanical strength, and outstanding electrical insulation properties.

This amorphous thermoplastic possesses a high glass transition temperature, which forms the foundational bedrock of its dimensional stability under thermal stress.

However, to meet the extreme demands of precision optics, this robust polymer matrix is compounded with a precise concentration of a specialized carbon fiber.

These are not typical long fibers but are engineered to a specific shorter length, creating a highly homogeneous reinforcement throughout the material.

This integration is the key to the transformative performance of PEI-LCF10. The carbon fibers drastically enhance the stiffness and tensile strength of the composite, effectively creating an internal skeleton that resists bending and deformation.

Simultaneously, the PEI matrix binds this reinforcement together, providing toughness, damage tolerance, and exceptional creep resistance.

The result is a material composite where the whole is profoundly greater than the sum of its parts. PEI-LCF10 delivers a unique profile of high modulus, low weight, and unparalleled stability, making it a purpose-engineered solution for applications where precision is non-negotiable.

The Critical Role of the Optical Lens Barrel

To fully appreciate the transformative impact of PEI-LCF10, one must first understand the critical function and demanding operating environment of a high-end optical lens barrel.

Whether housed within a cutting-edge semiconductor lithography machine, a deep-space telescope, a professional broadcast camera, or a high-resolution medical scanner, the lens barrel is the unsung hero of optical performance.

Its primary function is to maintain the exact spatial relationship between multiple optical elements—lenses, prisms, and filters—along a perfectly defined optical axis. Any deviation, however minute, leads to aberrations, focus shift, and a catastrophic loss of image quality.

This component operates under a host of stressors. It must resist mechanical deformation from its own weight, especially in large lenses.

It is subjected to constant thermal cycling, from the heat generated by internal electronics to fluctuations in ambient temperature. In many cases,

it must also maintain performance in a vacuum or under exposure to various wavelengths of light. Traditionally, aluminum has been a common choice, offering good machinability and strength, but its high thermal expansion and significant weight are major liabilities.

Alternative plastics can reduce weight but often introduce problems with creep, moisture absorption, and outgassing, which can contaminate sensitive optical surfaces. It is within this context of exacting requirements that PEI-LCF10 emerges as the superior material solution.

A Specific Application: The PEI-LCF10 Precision Lens Barrel

The implementation of a lens barrel machined from PEI-LCF10 stock material illustrates a perfect synergy between material properties and engineering requirements.

Consider the lens assembly in a high-precision coordinate measuring machine (CMM) used for industrial metrology.

This device must perform accurate three-dimensional measurements with micron-level repeatability in a factory environment where temperatures can vary.

The lens barrel in its optical scanning head is a critical component whose stability directly dictates the accuracy of the entire system.

The advantages of utilizing PEI-LCF10 begin with its exceptional dimensional stability. The coefficient of thermal expansion of a PEI-LCF10 composite is significantly lower than that of aluminum and most other engineering plastics.

This means that a lens barrel crafted from PEI-LCF10 will maintain its precise geometry and the critical alignment of the optical elements within it, even as the ambient temperature on the factory floor rises and falls.

This inherent thermal immunity ensures that the measuring machine’s calibration remains consistent throughout the day, eliminating measurement drift and guaranteeing data integrity.

This property is not just an improvement; it is a fundamental necessity for achieving and maintaining precision in real-world conditions.

Furthermore, the outstanding stiffness-to-weight ratio of PEI-LCF10 delivers profound benefits. A lens barrel constructed from this advanced composite will be markedly lighter than an equivalent aluminum part.

This reduction in mass lowers the moment of inertia in moving assemblies, allowing for faster acceleration and deceleration of the scanning head without sacrificing precision due to vibration or deflection.

This directly translates to higher throughput and faster measurement cycles on the production line, enhancing overall operational efficiency.

The inherent rigidity of PEI-LCF10 ensures that the barrel does not flex under its own weight or the load of the optical elements, preserving the perfect alignment of the optical path under all operational conditions.

The long-term reliability offered by a PEI-LCF10 lens barrel is another critical advantage. The material exhibits excellent resistance to creep, the tendency of a material to slowly deform under a constant mechanical load.

For a lens barrel that must support heavy glass elements for years, this property is non-negotiable; the component must not gradually sag or distort over time. Additionally, PEI-LCF10 demonstrates very low moisture absorption compared to other polymers.

This means the part will not swell in humid environments, a factor that could otherwise alter the precise positioning of the lenses and lead to focus errors or delamination of optical coatings.

The combination of creep resistance and hygroscopic stability ensures that an optical system built with a PEI-LCF10 barrel will deliver consistent, reliable performance over its entire operational lifespan, requiring less maintenance and recalibration.

The Superior Characteristics of PEI-LCF10 for Precision Optics

The successful application of PEI-LCF10 in a critical component like a metrology lens barrel is a direct result of its meticulously engineered portfolio of properties. The thermal performance of this composite is a cornerstone of its value proposition.

It possesses a high glass transition temperature, allowing it to retain its mechanical integrity and dimensional stability in elevated temperature environments that would cause many other plastics to soften.

This makes it suitable for applications near heat-generating components like light sources or motors.

Its resistance to thermal degradation ensures long-term reliability.

Mechanically, PEI-LCF10 is engineered for applications demanding precision and strength. The carbon fiber reinforcement provides a dramatic increase in modulus, making parts incredibly rigid and resistant to bending.

This high stiffness is essential for maintaining the alignment of optical elements. The composite also offers high tensile strength and excellent resistance to impact, protecting the valuable internal optics from damage caused by accidental knocks or drops.

The fatigue resistance of PEI-LCF10 ensures that the material can withstand prolonged periods of vibration without developing cracks or failing, a common requirement in industrial and aerospace settings.

From a manufacturing and finishing perspective, PEI-LCF10 offers significant advantages. Parts can be precision machined from extruded rods or plates to create prototypes or low-volume production runs with extremely tight tolerances.

The material machines cleanly, allowing for superb surface finishes that are often required for the internal baffling of a lens barrel to minimize light scattering.

For high-volume production, PEI-LCF10 is also suitable for injection molding, allowing for the cost-effective manufacturing of complex, net-shape components.

This versatility makes PEI-LCF10 an excellent choice for both custom, one-off designs and mass-produced optical assemblies. Its inherent properties also allow for compatibility with various coatings and platings if specific surface properties are required.

Conclusion: Redefining Optical Precision with PEI-LCF10

The integration of advanced composites like PEI-LCF10 is a pivotal development in the field of precision optics.

The example of the coordinate measuring machine lens barrel powerfully demonstrates how this specific material provides a holistic solution to a complex set of challenges.

It directly addresses the critical needs for unparalleled dimensional stability, lightweight construction, and long-term reliability. By enabling lighter, stiffer, and more thermally immune components,

PEI-LCF10 allows engineers to design optical systems with higher performance, greater accuracy, and improved efficiency.

PEI-LCF10 is more than just a material; it is a foundational technology that empowers innovation.

It allows optical designers to break free from the limitations imposed by traditional materials, paving the way for more advanced and capable devices in fields ranging from scientific research and industrial automation to medical imaging and consumer electronics.

As the demand for higher precision and greater reliability continues to grow across all technological sectors, materials like PEI-LCF10 will be at the forefront, enabling the next generation of optical breakthroughs.

Choosing PEI-LCF10 for a precision lens barrel is not merely a material selection—it is a strategic decision to invest in performance, quality, and leadership in optical engineering.

If you want to get more information about PEI-LCF60, you can visit our YouTube.

You can click here to contact us.

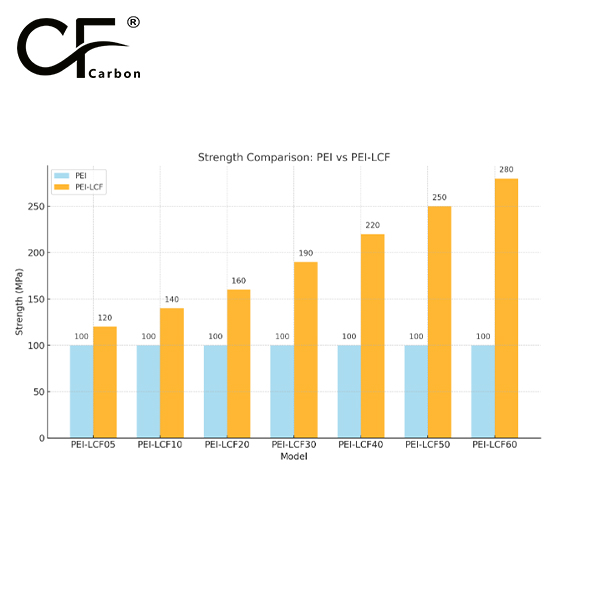

Strength between PEI and PEI-LCF

PEI-LCF offers strong mechanical properties, excellent thermal stability, and chemical resistance for moderate-duty applications. With the addition of low carbon fiber content, PEI-LCF enhances stiffness, wear resistance, and mechanical strength, making it suitable for environments that require balanced strength and durability under moderate stress.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.