PA66 CF Engineering-Grade Reinforced Nylon Composite - Carbon Fiber Compounds Manufacturer | Supplier

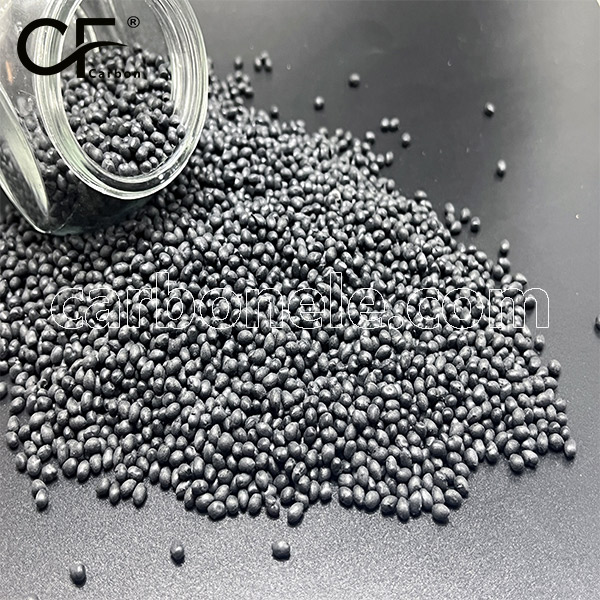

PA66 CF Engineering-Grade Reinforced Nylon Composite

PA66 CF represents an advanced engineering composite that combines the robust characteristics of Polyamide 66 with high-performance carbon fiber reinforcement. This material solution delivers exceptional mechanical properties and thermal stability for mission-critical applications across automotive, industrial, electronics, and aerospace sectors.

Material Advantages

1.Enhanced Thermal Performance

PA66 CF maintains structural integrity at continuous operating temperatures up to 220°C, with heat deflection temperature (HDT) reaching 255°C at 1.82 MPa. This thermal resistance exceeds standard PA66 by 40%, making it ideal for under-hood automotive components and high-temperature electrical systems.

2.Superior Mechanical Strength

The carbon fiber reinforcement provides:

*Tensile strength: 320 MPa

*Flexural modulus: 18 GPa

*Impact resistance 3x greater than unfilled PA66

These properties enable thinner, lighter designs without compromising structural requirements.

3.Weight Reduction Benefits

With a density of 1.38 g/cm³, PA66 CF components achieve 50-60% weight savings versus metal alternatives while maintaining equivalent strength characteristics. This advantage proves particularly valuable in automotive lightweighting and portable electronics applications.

4.Chemical Compatibility

Demonstrates excellent resistance to:

*Automotive fluids (oil, coolant, brake fluid)

*Industrial solvents

*Weak acids/alkalis

This chemical stability ensures long-term performance in aggressive environments.

Industrial Applications

1.Automotive Engineering

*Engine peripheral components

*Transmission system parts

*Structural reinforcement elements

PA66 CF contributes to vehicle weight reduction programs while meeting stringent automotive safety standards.

Electrical & Electronics

*High-temperature connectors

*Miniature circuit housings

*EMI shielding components

The material’s combination of dielectric properties and EMI shielding effectiveness (60-80 dB) addresses growing needs in 5G infrastructure and EV power systems.

Industrial Equipment

*High-wear gear components

*Chemical processing fixtures

*Robotic arm segments

PA66 CF withstands continuous mechanical stress while resisting chemical degradation in industrial environments.

Technical Development

Ongoing material innovations focus on:

*Increasing carbon fiber loading to 40%

*Developing laser-direct structuring (LDS) capabilities

*Optimizing flow characteristics for thin-wall molding

These advancements will further expand PA66 CF’s application potential in next-generation manufacturing.

Previous News

PPS CF10: Advanced CompositeNext News

PA66 LCF Reinforced Polymer for Lighter Aircraft

Feature Product

-

PA12 LCF30 for Drone Fuselages & Wings

What do you know about PA12 LCF30? PA12 ...

-

Competitive Price PA6 LCF30 Composites

What’s it? PA6 LCF30, which stands...

-

ABS CF10 Compound ABS 10%CF Thermoplastic Compo...

What’s ABS CF10? ABS CF10 refers t...