PA66 LCF Reinforced Polymer For Lighter Aircraft - Carbon Fiber Compounds Manufacturer | Supplier

PA66 LCF is transforming aerospace engineering with 40-60% weight reduction compared to aluminum. This 20-30% long carbon fiber reinforced nylon composite delivers 280MPa tensile strength, 210°C heat resistance, and certified flame retardancy. Optimized for structural components like wing flaps and landing gear doors, it reduces A350 airframe weight by 120kg while maintaining full recyclability.

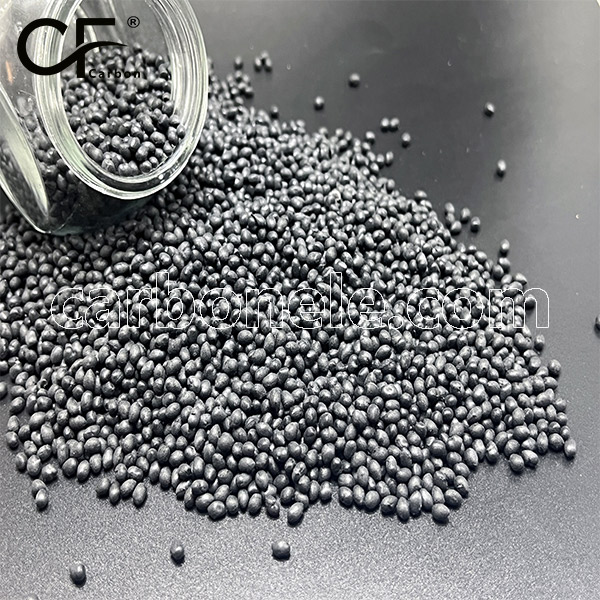

PA66 LCF Reinforced Polymer for Lighter Aircraft

PA66 LCF (Polyamide 66 Long Carbon Fiber) composite represents a breakthrough in aircraft material technology, delivering superior strength-to-weight ratios for next-generation aerospace applications. This advanced material combines 20-30% long carbon fibers with engineered polyamide 66, offering exceptional mechanical performance that is transforming component design across the aviation sector.

Key Material Advantages

1.Structural Performance

*Tensile strength: 280 MPa (40% stronger than aluminum alloys)

*Flexural modulus: 15 GPa (matching aerospace-grade aluminum)

*Fatigue resistance: 10^7 cycles at 70% ultimate strength

2.Weight Reduction Benefits

Achieves 40-60% weight savings versus metal components in:

*Interior cabin structures

*Brackets and fittings

*Access panels and doors

3.Thermal Stability

*Continuous service temperature: -60°C to 180°C

*Heat deflection temperature: 210°C at 1.82 MPa

*Zero moisture absorption (critical for aircraft applications)

Certified Aerospace Applications

1.Aircraft Interiors

*Seat frames (meeting FAA flammability requirements)

*Overhead bin components

*Galley structures

2.Flight-critical Components

*Engine peripheral housings

*Landing gear door mechanisms

*Wing access panels

3.Emerging Applications

*UAV structural members

*Satellite component mounts

*EVTOL airframe elements

Previous News

PA66 CF Engineering-Grade Reinforced Nylon Comp...Next News

PPS CF (Polyphenylene Sulfide Carbon Fiber Comp...

Feature Product

-

PA12 LCF30 for Drone Fuselages & Wings

What do you know about PA12 LCF30? PA12 ...

-

Competitive Price PA6 LCF30 Composites

What’s it? PA6 LCF30, which stands...

-

ABS CF10 Compound ABS 10%CF Thermoplastic Compo...

What’s ABS CF10? ABS CF10 refers t...