Short Vs. Long Carbon Fiber Reinforced Thermoplastics - Carbon Fiber Compounds Manufacturer | Supplier

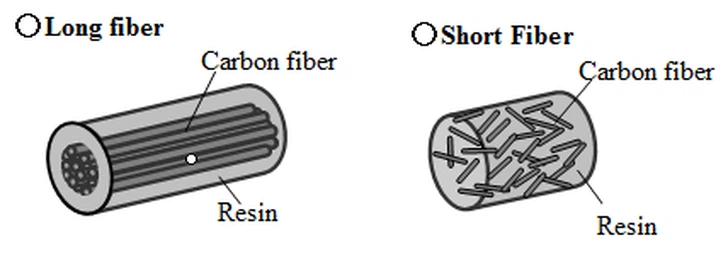

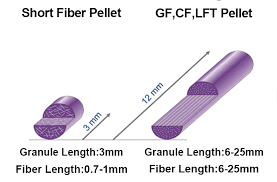

Carbon fiber reinforced thermoplastics (CFRTP) demonstrate significantly different mechanical properties depending on fiber length. Short fibers (3-6mm) and long fibers (10-50mm) each offer unique advantages for engineering applications. This comparison examines four key performance metrics: stiffness, tensile strength, fracture toughness, and impact resistance. While short fibers provide better processability and isotropic behavior, long fibers deliver superior mechanical performance through enhanced load transfer. The fiber length directly influences the composite’s anisotropy, with longer fibers creating more directional properties. Understanding these differences is crucial for material selection in aerospace, automotive, and industrial applications where specific mechanical requirements must be balanced against manufacturing considerations.

Carbon Fiber Reinforced Thermoplastics: Performance Comparison Between Short and Long Fibers and Industrial Application Selection

Introduction

Carbon Fiber Reinforced Thermoplastic (CFRTP) composites have become a core material in industries such as automotive and aerospace due to their lightweight properties, high strength, and design flexibility. The choice of fiber length (short fibers: 3-6mm vs. long fibers: 10-50mm) directly impacts material performance and processing techniques. Based on experimental data, this article systematically analyzes the differences between the two and provides selection recommendations for industrial applications.

1. Mechanical Properties: Long Fibers Dominate, Short Fibers Offer Isotropy

-

Strength and Stiffness

-

Long Fibers: With a continuous fiber network, tensile strength (200-400 MPa) and flexural modulus (15-30 GPa) are more than double those of short fibers (short fibers: 100-200 MPa, 8-15 GPa). For example, a long-fiber PPA automotive driveshaft achieves 30% weight reduction while increasing load capacity by 40%.

-

Short Fibers: Exhibit superior isotropic behavior (anisotropy <15%), making them suitable for multi-directional stress components.

-

-

Toughness and Impact Resistance

-

Long fibers show significantly higher fracture toughness (200-300 J/m²) and impact strength (150-300 J/m) compared to short fibers (50-100 J/m), but short fibers absorb energy more uniformly under complex deformations.

-

*Data Insight: Long fibers exhibit 60%-80% higher load transfer efficiency than short fibers.*

2. Processing Characteristics: Short Fibers for Complexity, Long Fibers Require Specialized Methods

-

Flowability and Adaptability to Complex Geometries

-

Short fibers typically have a 30%-50% higher melt flow index (MFI), enabling them to fill thin walls (<1mm) or micro-channels. For instance, in electronic connector injection molding, short-fiber materials achieve a 99.5% yield rate, while long fibers only reach 85%.

-

Long fibers require specialized screws and molds (e.g., shear-controlled screws), increasing equipment costs by 20%-30%.

-

-

Shrinkage and Dimensional Control

-

Short fibers have lower shrinkage rates (0.3%-0.8%) than long fibers (0.5%-1.2%), making them ideal for precision components like gears with tight tolerances (±0.05mm).

-

3. Cost Analysis and Typical Applications

-

Economic Considerations

-

Short-fiber materials are 15%-25% cheaper (same matrix) and reduce energy consumption by 10%-15%.

-

Long fibers’ superior performance can lower system costs (e.g., automotive suspension parts last 3x longer, reducing maintenance costs by 50%).

-

-

Industry Selection Guide

Scenario Recommended Type Reason Automotive Structural Parts Long Fibers High load & fatigue resistance Electronic Housings Short Fibers Complex geometry + low cost Drone Wings Long Fibers Lightweight & high specific strength Industrial Gearboxes Short Fibers Dimensional stability priority

4. Future Trend: Gradient Fiber Length Technology

Emerging “gradient fiber” technology (e.g., controlled 6-20mm distribution) balances flowability and mechanical performance. A case study on aerospace components shows a 40% improvement in impact strength while maintaining short-fiber processing efficiency.

Choosing between short and long fibers requires balancing performance, cost, and processing. With advancements in hybrid technologies, CFRTP will better meet industry needs and push the boundaries of lightweight design.

Previous News

Carbon Fiber Power: 5 Key Reasons It’s Revoluti...Next News

Why Are Auto Makers Switching to Carbon Fiber T...

Feature Product

-

PA12 LCF30 for Drone Fuselages & Wings

What do you know about PA12 LCF30? PA12 ...

-

Competitive Price PA6 LCF30 Composites

What’s it? PA6 LCF30, which stands...

-

ABS CF10 Compound ABS 10%CF Thermoplastic Compo...

What’s ABS CF10? ABS CF10 refers t...