Why Are Auto Makers Switching To Carbon Fiber Thermoplastics? - Carbon Fiber Compounds Manufacturer | Supplier

Auto makers are switching to carbon fiber thermoplastics (CFRTP) because they deliver lighter, stronger, and more sustainable solutions than metals. From Tesla to BMW, CFRTP is enabling next-gen vehicle design—and Carbon (Xiamen) is at the forefront of this revolution.

Ready to upgrade your materials? Contact us today!

Have you noticed how modern cars are getting lighter yet stronger? A decade ago, automakers relied heavily on steel and aluminum. But today, carbon fiber thermoplastics (CFRTP) are revolutionizing vehicle design. Why? Because they offer the perfect balance of strength, weight savings, and cost efficiency.

Take Tesla’s Cybertruck – its structural components use CFRTP to reduce weight while maintaining crash safety. Or BMW’s i3, which cut 300kg by replacing metal with carbon composites. But what exactly makes CFRTP the future of automotive manufacturing? Let’s break it down.

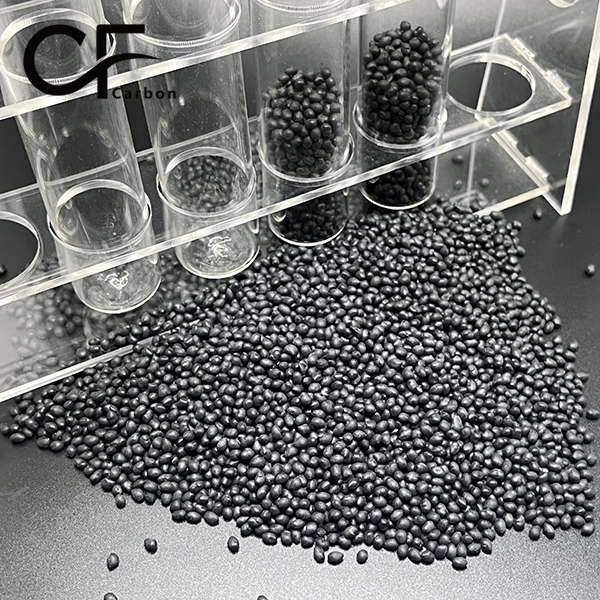

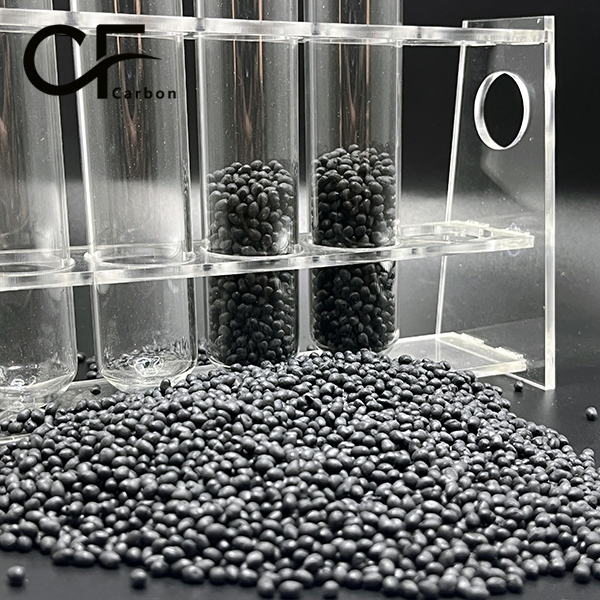

The Superiority of Carbon (Xiamen)’s CFRTP Materials

At Carbon (Xiamen) New Materials, we specialize in advanced carbon fiber-reinforced thermoplastics (CFRTP) engineered for automotive, aerospace, and industrial applications. Our materials outperform conventional plastics and metals in critical ways:

Unmatched Material Performance

-

PA66 CF20: Tensile strength 180MPa (vs. 80MPa for unfilled PA66)

-

PPA LCF40: Flexural modulus 25GPa (vs. 3GPa for standard PPA)

-

ABS CF10: Impact resistance 15kJ/m² (3X higher than pure ABS)

These materials also demonstrate exceptional thermal stability, with heat deflection temperatures up to 220°C (PPA CF40), and excellent resistance to fuels, oils, and UV degradation.

Industry-Leading Applications

Our CFRTP solutions are transforming multiple industries:

-

Automotive: Bumpers, battery housings, structural brackets

-

Aerospace: Interior panels, drone frames

-

Industrial: Robotics, conveyor systems

The advantages are clear:

✅ 50% lighter than steel

✅ 30% faster production cycles

✅ Corrosion-free & fully recyclable

Real-World Success Stories and Industry Insights

Expert Perspectives on Market Trends

“The shift to CFRTP is accelerating,” notes Dr. Alan Park, Materials Scientist at MIT. “By 2030, 40% of structural car parts will use composites.”

Recent case studies demonstrate this shift:

-

A European EV manufacturer reduced chassis weight by 22% using our PPA LCF40, improving battery range by 8%

-

According to SAE International, CFRTP reduces CO₂ emissions by 15% per vehicle

-

JEC Composites reports 20% annual growth in automotive CFRTP demand

Customer Experiences

Our global clients report exceptional results:

-

“Carbon (Xiamen)’s PA66 CF20 cut our part costs by 18% without sacrificing strength.” – AutoTech GmbH (Germany)

-

“Their PPA CF40 withstands 150°C in our drone motors – game-changer!” – AeroDynamic Inc. (USA)

-

“Fast delivery, consistent quality. Our go-to CFRTP supplier.” – Precision Molding Co. (Japan)

Answering Your CFRTP Questions

Q: Are carbon fiber thermoplastics stronger than steel?

A: Yes! CFRTP offers 5X higher strength-to-weight ratio than steel.

Q: What’s the best CFRTP for high-temperature applications?

A: PPA CF40 (HDT 220°C) outperforms nylon and ABS.

Q: How much weight can CFRTP save in cars?

A: Up to 50% vs steel, improving fuel efficiency.

Q: Is CFRTP recyclable?

A: Yes! Thermoplastic CFRTP can be remelted and reused.

Q: Where to buy high-quality CFRTP in bulk?

A: Carbon (Xiamen) New Materials offers wholesale CFRTP solutions.

The Future is CFRTP

Auto makers are switching to carbon fiber thermoplastics because they deliver lighter, stronger, and more sustainable solutions than metals. From Tesla to BMW, CFRTP is enabling next-gen vehicle design – and Carbon (Xiamen) is at the forefront of this revolution.

Our integrated approach combines R&D, production, and sales, backed by a professional team and modern facilities. We’re committed to providing high-quality carbon fiber reinforced thermoplastics, offering complete CFRTP solutions for your most demanding applications.

Ready to upgrade your materials? Discover how our CFRTP solutions can transform your products today.

Previous News

Short vs. Long Carbon Fiber Reinforced Thermopl...Next News

CarbonFuture @ ChengduPlas 2025

Feature Product

-

PA12 LCF30 for Drone Fuselages & Wings

What do you know about PA12 LCF30? PA12 ...

-

Competitive Price PA6 LCF30 Composites

What’s it? PA6 LCF30, which stands...

-

ABS CF10 Compound ABS 10%CF Thermoplastic Compo...

What’s ABS CF10? ABS CF10 refers t...