Nylon Parts Warping Again? Switch to PA12-CF10 for Dimensional Control

- Model number: PA12-CF-BCA1

- Matrix Resin: Polyamide12 (Nylon12)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Nylon Parts Warping Again? Switch to PA12-CF10 for Dimensional Control

If your nylon parts are warping under stress, heat, or humidity, you’re not alone. This issue affects countless industries that rely on conventional nylon for functional components. Fortunately, PA12-CF10 offers a powerful solution. Engineered with carbon fiber reinforcement, PA12-CF10 delivers exceptional dimensional stability while retaining the flexibility and toughness of base polyamide. It’s the next-generation material choice for professionals who demand consistency and long-term performance.

Superior Dimensional Control With PA12-CF10

Why Dimensional Stability Matters

In many precision applications, even minor deformation in plastic parts can lead to misalignment, vibration, failure, or safety concerns. Traditional nylon, while versatile and widely used, tends to absorb moisture and lose shape over time. This results in shrinkage, warping, and compromised fits in molded parts.

PA12-CF10 was developed to address these exact issues. By reinforcing polyamide 12 with carbon fibers, this material maintains its shape even when exposed to changing temperatures or mechanical loads. Whether in automotive brackets, drone housings, or functional prototypes, it ensures that every part performs just as designed, regardless of the environment.

The Role of Carbon Fiber Reinforcement

Carbon fiber within the polymer matrix enhances rigidity and limits expansion or contraction. It supports the polymer structure from within, distributing stress evenly and minimizing internal movement. Unlike unfilled nylons, PA12-CF10 stands firm against deformation, even under continuous use.

This makes it an ideal choice for engineers and manufacturers working with tight tolerances or operating conditions where failure is not an option.

One Material, Many Applications

Real-World Use Case: Automotive Sensor Mounting Brackets

Imagine a component that holds sensitive electronics in place near the engine bay of a car. The location exposes the part to heat, vibration, and moisture. If this bracket warps even slightly, the alignment of sensors may be thrown off, leading to data inaccuracies or system failure.

In such cases, PA12-CF10 becomes a reliable solution. It resists distortion and provides mechanical strength while maintaining the dimensional precision required for secure mounting. It also helps extend the life span of the part, reducing the need for maintenance or replacement over time.

This same level of performance can be applied to other industries as well, from aerospace to consumer electronics, where dimensional reliability is non-negotiable.

Process-Friendly and Production-Ready

Easy Integration Into Existing Systems

Despite its enhanced performance, PA12-CF10 remains compatible with most standard thermoplastic processing methods, including injection molding and extrusion. Manufacturers can adopt this material without the need for costly equipment changes or special tooling.

This seamless integration allows production teams to shift toward higher-quality components without sacrificing efficiency or increasing cycle times.

Reduced Scrap and Improved Yield

Using PA12-CF10 leads to fewer defective parts caused by shrinkage or surface distortion. In high-volume manufacturing environments, this translates into improved output consistency and reduced waste. Every part fits the design intent with higher accuracy, minimizing the need for post-processing adjustments or rework.

A Material Designed for the Long Run

Built to Withstand Challenging Conditions

Parts made from PA12-CF10 retain their shape and function across a wide range of demanding environments. From heat-exposed automotive interiors to outdoor electronic enclosures, this material remains stable and performs reliably.

Unlike conventional plastics that may soften, warp, or crack over time, PA12-CF10 is engineered for long-term use. It is especially well-suited for applications where parts must maintain structural integrity over months or years.

Consistent Appearance and Surface Quality

Carbon fiber not only improves strength but also contributes to the visual appearance of finished parts. PA12-CF10 components offer a refined, uniform surface finish that conveys quality and professionalism. Whether you’re delivering B2B industrial parts or consumer-facing products, this material meets the high aesthetic standards often demanded in today’s competitive market.

Why Choose PA12-CF10 for Your Project

PA12-CF10 offers the ideal combination of mechanical reliability, dimensional precision, and ease of processing. For designers, engineers, and manufacturers seeking to solve the common pitfalls of traditional nylon, this material provides a future-proof alternative.

If you’ve been dealing with inconsistent part performance, dimensional drift, or product failures tied to material instability, now is the time to make the switch. PA12-CF10 represents a new standard in polymer engineering—one built for accuracy, durability, and long-term peace of mind.

If you want to get more information about PA12-CF10, you can visit our Youtube.

Click here to contact us.

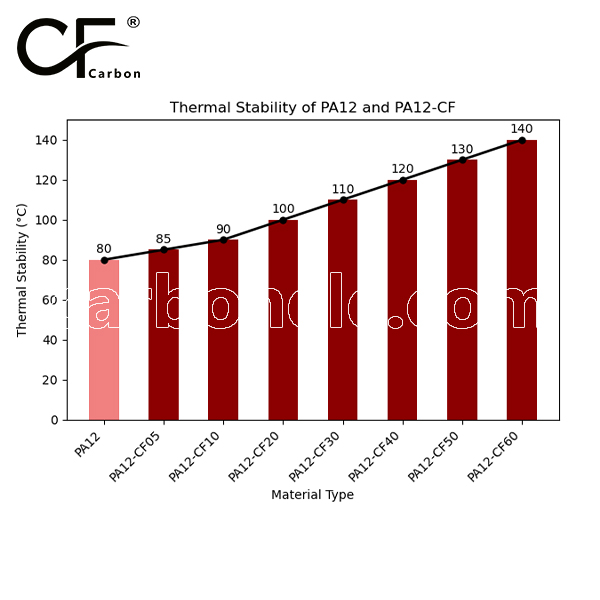

Thermal Stability of PA12-CF

PA12-CF composites exhibit significantly enhanced thermal stability compared to standard PA12 due to the incorporation of carbon fiber. As the carbon fiber content increases, the material's ability to withstand elevated temperatures improves, allowing it to maintain mechanical properties in high-temperature environments. This enhanced heat deflection temperature makes PA12-CF suitable for applications that require reliable performance under thermal stress. The superior thermal stability ensures that components made from PA12-CF can operate effectively in demanding conditions, thereby expanding their usability across various industries, including automotive and aerospace. The combination of lightweight characteristics and improved heat resistance positions PA12-CF as an excellent choice for applications that prioritize both strength and thermal performance.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

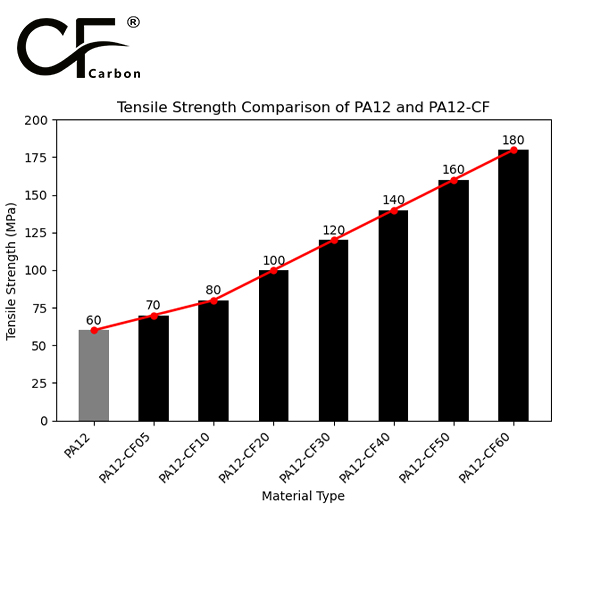

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.