Low Moisture Absorption PA12 CF Pellets for FGF 3D Printers

PA12 CF Pellets Feature:

1. Low moisture absorption-<0.5%(vs 2.5% PA6)

2.High stiffness -12 GPa modulus(2xunfilled PA12)

3. Excellent thermal stability-CTE~20×10-/℃

4. FGF-optimized – <1% shrinkage, >95% interlayer adhesion

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free samples: ≤10kg

- MOQ: 100kg

- Port: Xiamen

- Model: PA12-CF-BCA3

- Fillers: SCF/LCF

PA12 CF Pellets Overview:

Low Moisture Absorption PA12 CF Pellets are a carbon fiber-reinforced polyamide 12 (PA12) composite optimized for fused granulate fabrication (FGF) 3D printing. The material combines PA12’s excellent layer adhesion and thermal stability with carbon fiber’s reinforcement, ensuring high strength, stiffness, and minimal moisture uptake—critical for large-format additive manufacturing.

Suitability for FGF 3D Printing:

-

Low Moisture Absorption (<0.5%) – Unlike standard nylons (e.g., PA6 ~2.5%), PA12 CF resists humidity-induced swelling, preventing print warping and ensuring dimensional accuracy in humid environments.

-

Enhanced Stiffness & Strength – With a tensile modulus of ~12 GPa and strength of ~200 MPa, printed parts maintain rigidity under load, ideal for functional prototypes and industrial tooling.

-

Thermal Stability – Low CTE (~20 × 10⁻⁶/°C) minimizes thermal deformation during printing, enabling precise large-scale builds without warping.

-

FGF Compatibility – Pellet form allows cost-efficient, high-speed printing vs. filaments, with carbon fiber improving flowability and reducing shrinkage (<1%).

Compared to unfilled PA12, PA12 CF pellets reduce moisture uptake by 80% while doubling stiffness. FGF-printed parts exhibit >95% interlayer adhesion strength, critical for structural applications.

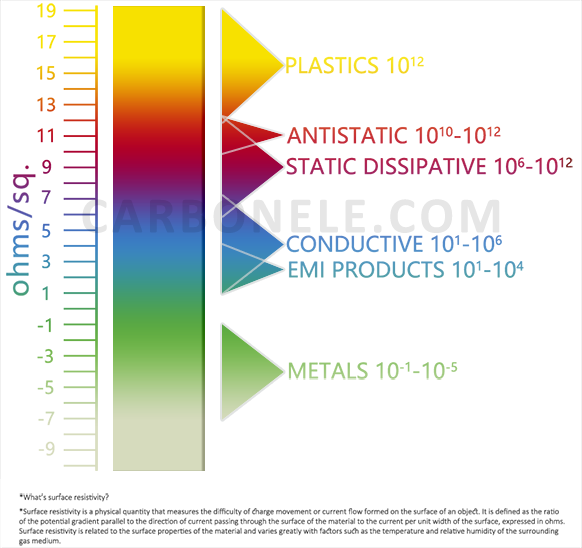

Surface Resistivity Comparison

Conductors < 10⁵ Ω/sq. Antistatic Materials 10⁵ ~ 10¹² Ω/sq. Insulators > 10¹² Ω/sq. Static-Dissipative 10⁶ ~ 10¹¹ Ω/sq. *Key Influencing Factors Humidity: Increased moisture can reduce resistivity (e.g., in polymers). Temperature: Affects carrier mobility (↑ heat may lower semiconductor resistivity). Surface Contamination: Dust/oils alter readings significantly. Additives: Carbon black, metallic fillers can lower resistivity. *Applications Electronics: Antistatic materials (10⁶–10⁹ Ω/sq) prevent electrostatic discharge (ESD). Aerospace: Composites must control resistivity to avoid charge buildup. Medical Devices: Insulating materials (>10¹² Ω/sq) ensure patient safety. *Examples Polypropylene (PP): ~10¹⁶ Ω/sq (excellent insulator). Carbon Fiber Composites: 10³–10⁶ Ω/sq (static dissipation). ESD Flooring: 10⁶–10⁹ Ω/sq.

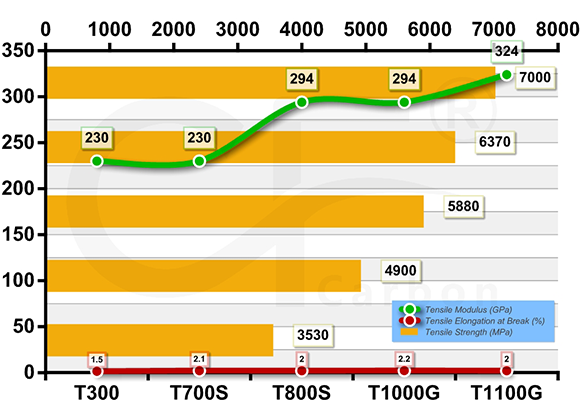

Get to Know Carbon Fibers

The table presents key performance data of carbon fiber grades. T300, with a tensile strength of 3530 MPa and a tensile modulus of 230 GPa, has a relatively low tensile elongation at break of 1.5% and a body density of 1.76 g/cm³. As the grade increases, for example, T700S shows an enhanced tensile strength of 4900 MPa compared to T300, while maintaining the same tensile modulus but with a higher elongation at break of 2.1%. T800S and T1000G both have a tensile modulus of 294 GPa, and their tensile strengths are 5880 MPa and 6370 MPa respectively. T1100G stands out with the highest tensile strength of 7000 MPa and a tensile modulus of 324 GPa. Generally, with the increase in product grade, the tensile strength and modulus tend to rise, while the density remains relatively stable around 1.8 g/cm³.

How to Buy?

If you want to obtain information such as product specifications, performance, and price, choose a suitable product according to your own needs. Meanwhile, you can ask the manufacturer to provide samples for testing to ensure that the material meets your usage requirements. If you are interested in purchasing this composite material, please contact the manufacturer Carbon (Xiamen) New Material directly.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.