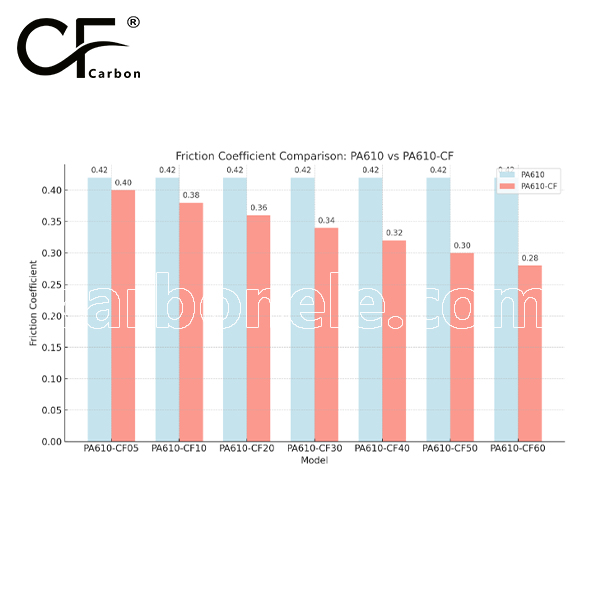

The friction coefficient of PA612 (polyamide 612) is typically around 0.3 to 0.4 when sliding against steel or other metal surfaces. However, when carbon fiber is incorporated into PA612 to create PA612-CF, the friction coefficient tends to decrease due to the lubricating effect of the carbon fibers. For PA612-CF, the friction coefficient generally ranges from 0.2 to 0.3, depending on the percentage of carbon fiber reinforcement and the specific testing conditions. The addition of carbon fiber improves wear resistance and helps reduce friction, making PA612-CF more suitable for high-stress applications requiring low friction and long-term durability.

One Material Swap to PA610-CF30 Could Save Your Design

Upgrade your design with PA610-CF30—a carbon fiber reinforced nylon offering superior strength, stability, and reliability in demanding applications.

- Model number: PA610-CF-BCA3

- Matrix Resin: PA from Hexamethylene diamine and Sebacic acid (PA610)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

One Material Swap to PA610-CF30 Could Save Your Design

When a plastic component fails, it is rarely the shape or size that is to blame. More often, it is the material. Engineers across industries are discovering that replacing standard nylon with PA610-CF30 can prevent cracking, deformation, and fatigue—especially in structural and load-bearing parts. If you’ve been struggling with nylon parts that don’t hold up under stress, one material swap could change everything.

Why Designers Choose PA610-CF30 for Critical Parts

Stronger by Structure, Reliable by Design

PA610-CF30 is a carbon fiber-reinforced nylon 610, engineered to bridge the gap between strength and flexibility. Unlike conventional nylons that tend to deform or warp under pressure or heat, PA610-CF30 maintains dimensional stability. This makes it ideal for parts that must retain their shape, fit precisely, and endure daily wear.

Whether you’re designing automotive housings, mechanical brackets, or load-distribution panels, this material offers a performance upgrade without major design changes.

Real-World Scenario: Fixing a Failing Automotive Bracket

Imagine an automotive engineer working on an under-the-hood bracket—a part exposed to continuous vibration, elevated temperatures, and significant mechanical loads. Originally produced using standard PA610, the part repeatedly fractured near the mounting points after only a few months of use.

The solution? Swapping to PA610-CF30. With its carbon fiber reinforcement, the bracket’s stiffness increased without becoming brittle. Thermal resistance improved. And most importantly, the failures stopped. The same mold was used—only the material changed. That one switch not only saved the part but also restored confidence in the entire design.

Key Benefits of PA610-CF30

Superior Mechanical Strength for Demanding Applications

Thanks to the carbon fiber content, PA610-CF30 dramatically improves structural performance over unfilled PA610. It supports greater loads, resists deformation, and withstands continuous stress. This makes it an excellent choice for parts under mechanical strain or torque.

Dimensional Stability in Harsh Conditions

In applications where heat, humidity, or chemical exposure is present, PA610-CF30 outperforms traditional nylons. The fiber reinforcement helps lock in part geometry, reducing warping, creep, or misalignment over time—a critical factor for parts that interface with tight tolerances.

Lightweight Without Compromise

Even with added reinforcement, PA610-CF30 remains a lightweight alternative to metals. It’s especially valuable in industries where weight savings translate to better energy efficiency—such as transportation, robotics, and portable equipment.

Common Applications of PA610-CF30

Automotive Components

Brackets, clips, underbody housings, and fluid connectors benefit from PA610-CF30’s balance of stiffness and thermal resistance. Its low moisture absorption compared to other nylons also enhances long-term stability in engine compartments.

Industrial and Mechanical Parts

Gear housings, bearing supports, and tension arms made from PA610-CF30 resist fatigue and wear even in dynamic environments. It provides the mechanical durability of engineering thermoplastics with enhanced rigidity.

Sports and Recreation Equipment

From bike parts to performance gear, PA610-CF30 adds structural integrity without increasing weight. Its strength-to-weight ratio gives designers freedom to innovate in high-impact consumer products.

Why PA610-CF30 is an Ideal Material Upgrade

Drop-In Ready for Existing Molds

In many cases, PA610-CF30 can be used without redesigning tooling or molds. It shares many base characteristics with PA610, making it an efficient upgrade path for improved performance without the cost of retooling.

Long-Term Value, Reduced Failure Rate

While the upfront material cost may be higher than standard PA610, the lifecycle savings are significant. Fewer failures mean fewer replacements, less downtime, and higher user satisfaction.

Sustainable and Forward-Thinking

PA610-CF30 is also more sustainable than traditional short-life plastics. Its durability reduces waste, and its base polymer is partially bio-based, making it a smarter choice for forward-thinking brands.

Make the Switch to PA610-CF30 Today

Choosing the right material can mean the difference between a part that performs and one that fails under pressure. If you’ve been let down by warping, cracking, or mechanical breakdowns in your nylon-based parts, PA610-CF30 offers a proven solution.

One material change. That’s all it takes to protect your design, your product, and your reputation. Make the switch to PA610-CF30 now and experience the difference in performance and reliability.

If you want to get more information, you can visit our YouTube

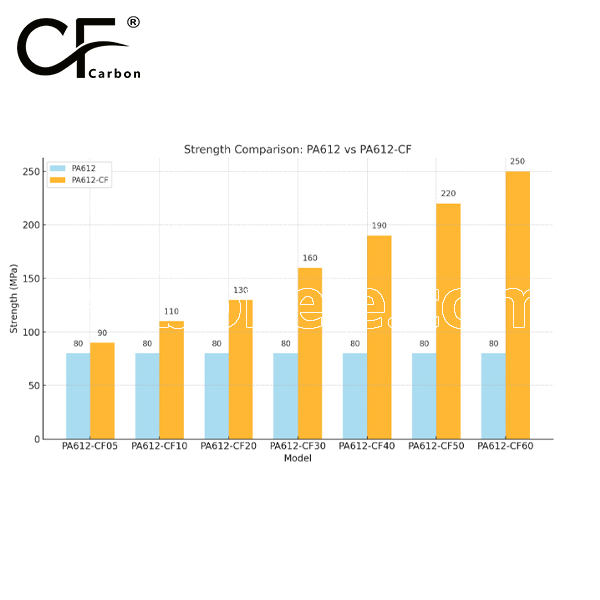

Strength between PA610 and PA610-CF

Compared to PA610, PA610-CF exhibits significantly higher strength. PA610 typically has a tensile strength ranging from 50-70 MPa and a flexural strength around 80-100 MPa, making it suitable for low-load applications. In contrast, PA610-CF, with 5% carbon fiber reinforcement, boosts its mechanical properties, achieving a tensile strength of 90 MPa, a flexural strength of 130 MPa, and an impact strength of 4.0 kJ/m². These improvements make PA610-CF more suitable for high-load, wear-resistant, and impact-resistant applications in demanding industrial environments.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.