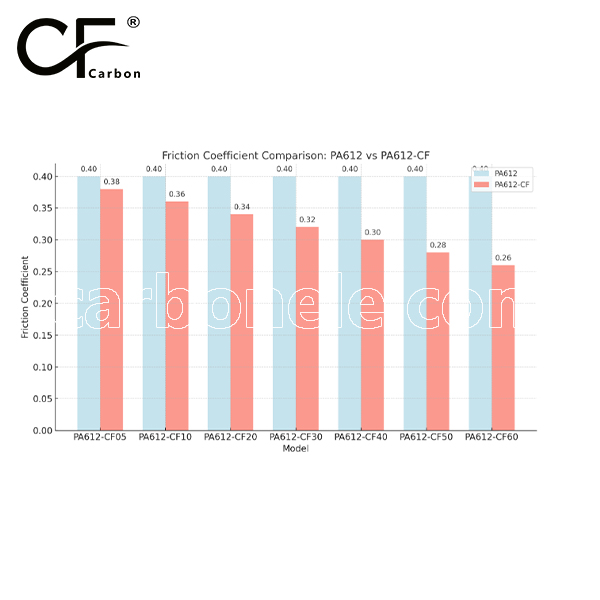

The friction coefficient of PA612 is typically around 0.3 to 0.4, while PA612-CF (carbon fiber reinforced) has a lower friction coefficient, ranging from 0.2 to 0.3, due to the lubricating effect of the carbon fibers. This results in reduced friction and improved wear resistance for PA612-CF.

PA612-CF10 Stops Moisture Swell in Structural Nylon Applications

PA612-CF10 offers moisture-resistant strength for structural nylon parts. Ideal for outdoor, load-bearing applications that demand dimensional stability.

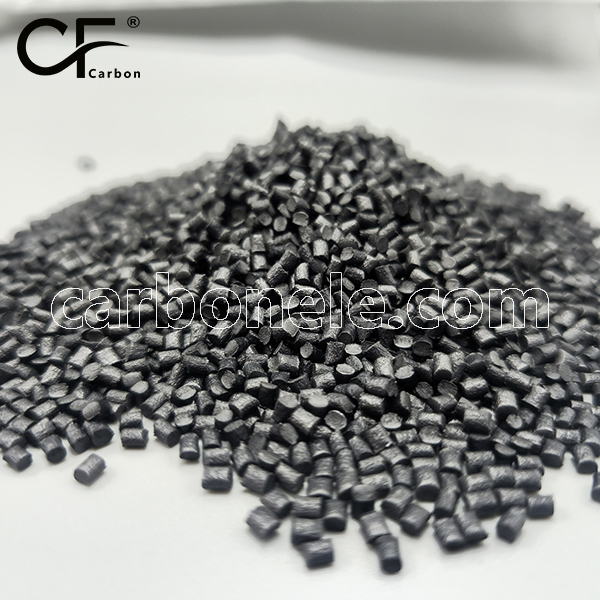

- Model number: PA612-CF-BCA1

- Matrix Resin: Polyhexamethylene dodecanamide (PA612)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PA612-CF10 Stops Moisture Swell in Structural Nylon Applications

When engineers choose nylon for demanding structural components, they often run into a familiar problem: moisture absorption. Standard nylons like PA6 or PA66 swell in humid environments, distorting dimensions, weakening parts, and ultimately causing product failures. PA612-CF10 provides a reliable solution by combining dimensional stability with carbon fiber reinforcement—ideal for structural nylon applications that demand long-term performance in fluctuating environments.

Why Moisture Swell Destroys Structural Integrity

Structural nylon components are often used in environments where moisture is unavoidable—such as under-the-hood automotive parts, outdoor power equipment, and industrial enclosures. Over time, these parts absorb water, leading to swelling, warping, and even loss of mechanical strength. Designers and manufacturers are then forced to over-engineer components or tolerate performance drops.

This is where PA612-CF10 makes a dramatic difference. By using a longer-chain nylon matrix (PA612) and reinforcing it with carbon fibers, this composite resists moisture absorption while preserving its geometry and load-bearing capabilities.

The Application: Mounting Brackets in Outdoor Power Equipment

Let’s look at a specific case: structural mounting brackets used in outdoor lawn and garden equipment. These brackets must secure moving assemblies and bear frequent vibration. They are constantly exposed to moisture—through rainfall, ambient humidity, or water spray from cleaning. Traditional nylon parts often fail over time, becoming misshapen and brittle due to water-induced swelling.

By switching to PA612-CF10, manufacturers of these brackets achieve a key advantage: the part retains its shape and performance after repeated exposure to wet environments. The carbon fiber reinforcement keeps the material stiff and strong, while the PA612 base resists water uptake much more effectively than conventional nylon.

As a result, the brackets stay aligned, fasteners remain secure, and end users experience fewer product failures. This leads to better brand reputation, fewer warranty claims, and longer product life cycles.

Dimensional Stability That Designers Can Trust

One of the core benefits of PA612-CF10 is its exceptional dimensional stability. This property is especially critical for components that interact with other precision parts. Whether it’s a gear housing, a structural frame, or a connector base, even a slight swelling in one part can misalign an entire assembly.

With PA612-CF10, engineers can design parts with tighter tolerances, knowing they won’t drift due to humidity or seasonal changes. This opens new possibilities for applications that were once off-limits to nylon-based materials.

Improved Machinability and Surface Finish

Another hidden benefit of PA612-CF10 is the improved machinability compared to glass-filled alternatives. When a nylon part needs post-processing—such as drilling, trimming, or surface finishing—carbon fiber reinforcement reduces tool wear and yields smoother surfaces. This is especially useful in small batch production or applications where a clean, finished look matters.

Because PA612-CF10 offers this ease of processing, it’s not just a better-performing material—it’s a more economical one in many real-world workflows.

A Drop-In Upgrade for Moisture-Prone Environments

Many manufacturers are now looking for drop-in replacements that don’t require mold redesign or recertification. PA612-CF10 is often compatible with existing molds designed for PA6 or PA66. The material flows well during molding, and its warpage behavior is more predictable—meaning fewer molding defects and less scrap.

This allows product developers to upgrade their designs without incurring high tooling costs. In markets where lead time and production agility matter, this is a major competitive edge.

Lightweight Strength with a Carbon Fiber Advantage

The carbon fiber content in PA612-CF10 not only boosts mechanical strength but also keeps parts lightweight. This makes it a smart option in weight-sensitive designs, especially in the automotive, aerospace, and portable equipment industries.

While traditional metal parts offer strength, they come with weight penalties and corrosion concerns. PA612-CF10 allows engineers to achieve a strong, moisture-resistant structure—without the drawbacks of metal.

When to Choose PA612-CF10

Use PA612-CF10 when your application involves:

-

High humidity or outdoor exposure

-

Structural loads or stress-bearing parts

-

Tight dimensional tolerances

-

Need for reduced warping and swelling

-

Lightweight design goals

-

Compatibility with PA6/PA66 tooling

-

Better machinability for secondary operations

This material is particularly well-suited to applications such as brackets, enclosures, support frames, and functional housings in rugged or moisture-prone environments.

Final Thoughts—Performance Without Compromise

Designers no longer need to choose between strength and stability in nylon components. With PA612-CF10, you get both. Its combination of low moisture absorption and carbon fiber reinforcement solves the long-standing problem of dimensional shift in nylon structures.

Whether you’re facing part failures in the field or want to future-proof your product lineup, PA612-CF10 offers a drop-in solution that performs better, lasts longer, and gives your engineering team more room to innovate.

If you want to get more information about PA612-CF10, you can visit our YouTube.

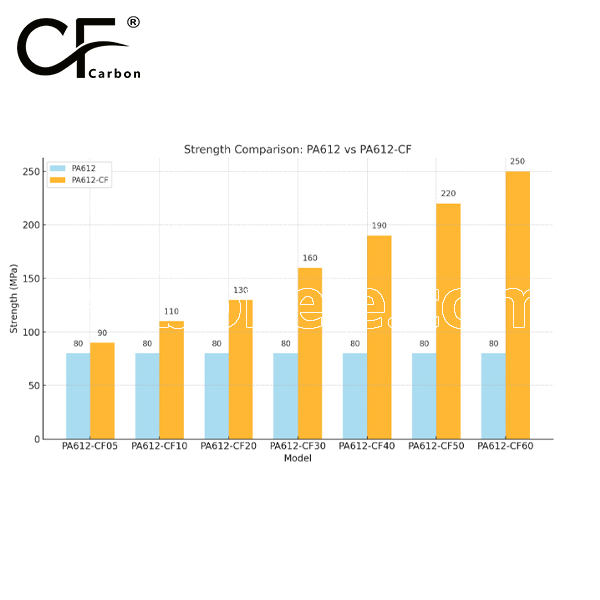

Strength between PA612 and PA612-CF

PA612 is a strong, chemically resistant nylon with good wear properties, but its mechanical strength is moderate. PA612-CF is the carbon fiber reinforced version, offering significantly higher tensile and flexural strength, improved stiffness, and better wear resistance, making it ideal for high-performance applications.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.