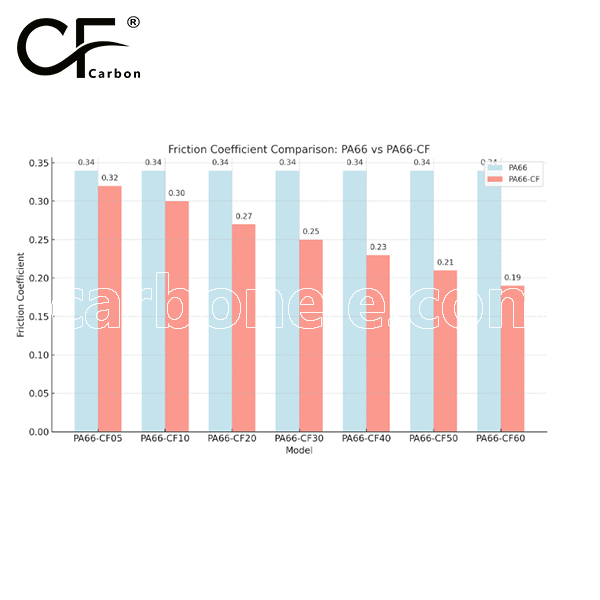

The friction coefficient of PA66-CF is significantly lower than that of unreinforced PA66, thanks to the presence of carbon fiber, which acts as a solid lubricant. While PA66 already offers decent wear resistance, the addition of carbon fiber greatly enhances its tribological performance by reducing surface friction and improving wear resistance under load and repeated motion. This makes PA66-CF especially suitable for applications involving sliding contact or dynamic mechanical stress.

PA66-CF10 Carbon Fiber Nylon for Auto Parts

PA66-CF10 combines nylon’s versatility with 10% carbon fiber reinforcement, delivering 210MPa tensile strength and 255°C heat resistance. Ideal for automotive, electronics and industrial applications requiring lightweight metal alternatives with superior strength and dimensional stability.

- Model number: PA66-CF-BCA1

- Matrix Resin: Polyamide66

- Reinforcing Filler: Carbon fiber(10%)

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PA66-CF10: High-Performance Carbon Fiber Reinforced Nylon for Demanding Applications

PA66-CF10 is an engineering-grade thermoplastic composite composed of polyamide 66 (Nylon 66) reinforced with 10% long carbon fibers. This advanced material combines the inherent benefits of nylon—such as chemical resistance and processability—with the superior strength, stiffness, and thermal stability imparted by carbon fiber reinforcement. Ideal for applications requiring lightweight yet durable alternatives to metals, PA66-CF10 excels in high-stress, high-temperature environments across automotive, aerospace, and industrial sectors.

Key Technical Properties

Mechanical Performance

Tensile Strength: 180–210 MPa (2–3× higher than unfilled PA66)

Flexural Modulus: 9,500–11,000 MPa (near aluminum’s stiffness-to-weight ratio)

Impact Strength: 90 kJ/m² (maintains ductility at -40°C)

Fatigue Resistance: 10⁷ cycles at 70% of yield stress (for dynamic load applications)

Thermal & Electrical Properties

Heat Deflection Temperature (HDT): 255°C at 1.82 MPa (vs. 90°C for standard PA66)

Continuous Service Temperature: Up to 180°C in dry conditions

Coefficient of Thermal Expansion (CTE): 2.5 × 10⁻⁵ /°C (50% lower than unfilled nylon)

Electrical Conductivity: Surface resistivity of 10³–10⁵ Ω (effective for ESD/EMI shielding)

Chemical & Environmental Resistance

Hydrolysis Resistance: Withstands 5,000+ hours in 85°C/85% RH (critical for under-hood parts)

Chemical Resistance: Immune to automotive fluids (oil, coolant, brake fluid)

UV/Weathering Stability: Carbon fibers reduce UV degradation vs. unreinforced nylons

Automotive Electronics Application Spotlight: EV Battery Module Housings

Challenge: Traditional materials (aluminum or standard plastics) face trade-offs between weight, corrosion resistance, and EMI shielding in high-voltage battery enclosures.

PA66-CF10 Solution:

-

Weight Reduction: 40% lighter than aluminum housings, improving energy efficiency.

-

Thermal Management: Maintains dimensional stability during rapid charge/discharge cycles (ΔT > 100°C).

-

EMI Shielding: 30–40 dB attenuation protects sensitive battery management systems.

-

Design Flexibility: Enables complex, integrated geometries unachievable with metals.

Performance Data vs. Alternatives:

| Property | PA66-CF10 | Aluminum 6061 | Standard PA66 |

|---|---|---|---|

| Density (g/cm³) | 1.32 | 2.70 | 1.14 |

| Tensile Strength (MPa) | 210 | 310 | 80 |

| CTE (×10⁻⁶/°C) | 25 | 23 | 50 |

| Cost (Index) | 1.5 | 1.0 | 1.0 |

Processing Guidelines

Injection Molding:

-

Drying: 4–6 hours at 80–90°C (moisture ≤ 0.1%)

-

Melt Temp: 280–300°C (optimized for fiber dispersion)

-

Mold Temp: 80–100°C (reduces warpage)

-

Injection Speed: Moderate-to-high (prevents fiber separation)

Post-Processing:

-

Machining: Use carbide tools (carbon fibers are abrasive).

-

Joining: Ultrasonic welding or structural adhesives (avoid screws in load-bearing areas).

Why Choose Our PA66-CF10?

Controlled Fiber Length Distribution: 1–2mm fibers ensure uniform reinforcement.

Custom Formulations: Adjust fiber content (5%–30%) or add flame retardants.

Technical Support: Our material engineers assist with DFM (Design for Manufacturing).

Global Supply Chain: Consistent quality across US/EU/Asia production hubs.

If you want to get more information about PA66-CF10, you can visit our Youtube.

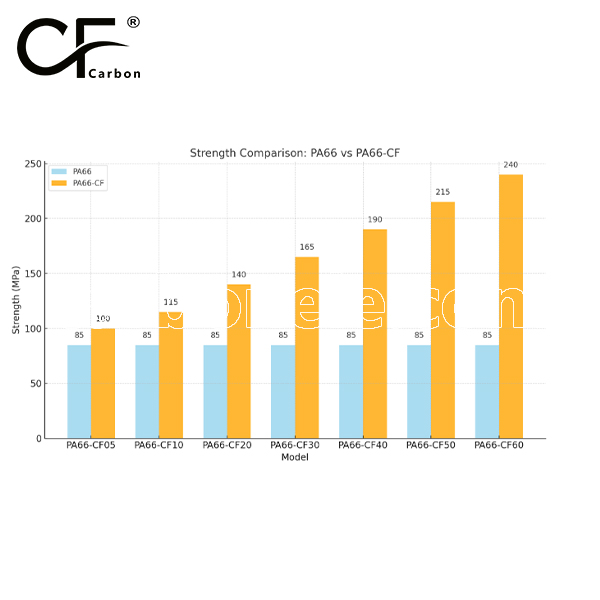

Strength between PA66 and PA66-CF

Compared to unreinforced PA66, PA66-CF (carbon fiber reinforced) offers significantly higher strength and stiffness. The addition of carbon fiber increases tensile and flexural strength, enhances dimensional stability, and reduces deformation under load. While standard PA66 provides good toughness and impact resistance, PA66-CF materials are better suited for structural and high-stress applications where superior mechanical performance is required.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.