PA66-CF20 Enhanced Nylon – Superior Sports Equipment

PA66 CF20 is a high-performance engineering thermoplastic reinforced with 20% carbon fiber, delivering outstanding mechanical properties including a tensile strength of 180-200 MPa and flexural modulus of 12-14 GPa. With a heat deflection temperature of 255°C, this material provides excellent thermal stability for demanding applications. The carbon fiber reinforcement significantly enhances dimensional stability while maintaining good chemical resistance to oils and coolants.

- Model Number: PA66-CF-BCA2

- Matrix Resin: Polyamide 66 (PA66)

- Reinforcing Filler: 20% Carbon Fiber

- Appearance: Natural Black Granules

- Packaging: 25kg/bag

Introduction to PA66-CF20

PA66-CF20 is a high-performance engineering material that combines the strength of carbon fiber with the reliability of nylon. This advanced composite offers a balance of toughness, resilience, and lightweight properties, making it a sought-after choice in demanding industries. In sports equipment, where durability and precision are critical, it provides designers and manufacturers with a material that elevates both performance and longevity.

Why PA66-CF20 is a Game-Changer

Every material used in sports equipment carries the responsibility of enhancing an athlete’s performance. Traditional polymers may lack the durability needed for repeated use, while metals often add excessive weight.It overcomes these limitations by delivering structural strength without compromising weight efficiency. Its versatility makes it suitable for gear that demands impact resistance, ergonomic design, and long-term reliability.

Unique Advantages of PA66-CF20

-

Enhanced mechanical stability under demanding conditions

-

Excellent resistance to wear and repeated stress

-

Lightweight nature for ergonomic equipment designs

-

Dimensional stability for consistent performance

These qualities collectively position PA66-CF20 as a superior alternative to conventional plastics and metals in sports gear.

Application Spotlight: Sports Equipment Handles

One of the most practical uses of PA66-CF20 can be seen in sports equipment handles, such as those found in professional rackets or training gear. A handle manufactured with PA66-CF20 offers athletes a solid yet comfortable grip, reducing fatigue during extended use. The carbon fiber reinforcement ensures the handle resists cracking, warping, or wearing down, even under high-intensity training sessions. Compared to traditional nylon handles, it handles maintain their shape and reliability, giving players a competitive advantage.

Structural Benefits of PA66-CF20

When designing sports equipment, material selection is not only about strength but also about maintaining a balance between resilience and flexibility. it provides:

-

Stability that withstands continuous movement

-

A lightweight profile that supports agile performance

-

Resistance to fatigue, ensuring consistent usability over time

This makes it a material of choice for manufacturers aiming to create products that endure the pressures of professional and recreational use.

PA66-CF20 in Modern Sports Gear Innovation

As sports technology continues to evolve, athletes and manufacturers alike search for materials that can keep pace with modern demands. PA66-CF20 allows engineers to create designs that push the boundaries of traditional equipment. From racket frames to protective guards, this material delivers the durability athletes rely on without unnecessary bulk.

Key Roles in Sports Equipment

-

Rackets and sticks: Ensures precision, control, and strength

-

Protective gear: Maintains integrity under impact

-

Fitness machines: Offers long-lasting support in structural parts

-

Handles and grips: Delivers comfort with resilience

Why Choose PA66-CF20 Over Alternatives

Manufacturers who adopt PA66-CF20 in their production lines gain a competitive edge. Unlike standard nylons, which may deform over time, or metals, which often increase overall weight, it bridges the gap. Its balance of performance and design flexibility helps brands deliver sports equipment that meets athlete expectations while maintaining long-term durability.

Long-Term Reliability of PA66-CF20

Sports gear is subject to rigorous conditions: repeated stress, environmental exposure, and constant handling. It has the resilience to maintain structural integrity under these circumstances. This long-term reliability makes it an excellent material for athletes who expect their equipment to perform consistently throughout training sessions and competitions.

Expanding Applications Beyond Sports

While PA66-CF20 excels in sports gear, its applications extend into automotive, industrial, and consumer goods. Its balance of lightweight design and structural strength makes it ideal for components that require both endurance and reduced weight. Manufacturers can rely on PA66-CF20 across industries where precision and reliability are non-negotiable.

Conclusion: The Future with PA66-CF20

PA66-CF20 is more than a material; it is a solution for industries and athletes alike. By enhancing the durability and functionality of sports equipment, it contributes to better performance and user satisfaction. Whether it’s a professional racket handle, protective sports gear, or structural components in training equipment, it demonstrates why advanced composites are shaping the future of material innovation.

If you want to get more information about PPSU-CF60, you can visit our YouTube.

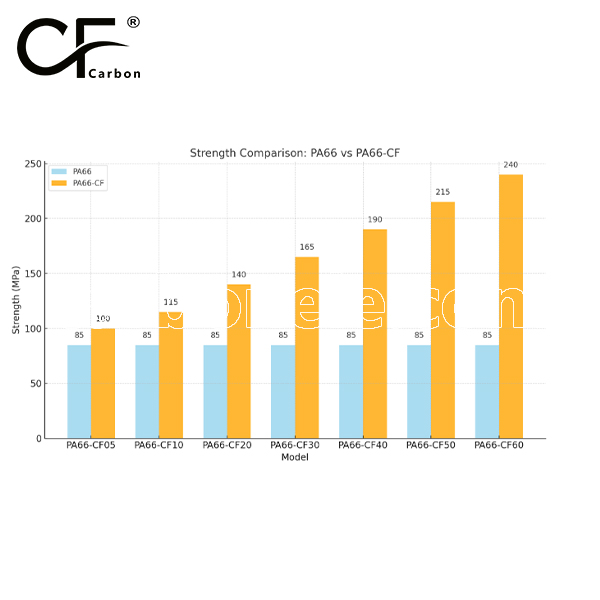

PA66 CF20 vs Standard PA66 Strength Comparison

PA66-CF20 (20% carbon fiber reinforced PA66) delivers significantly higher mechanical strength and rigidity compared to standard PA66. The carbon fiber reinforcement improves tensile strength, flexural strength, and wear resistance, making PA66-CF20 ideal for high-stress and harsh environment applications. While standard PA66 works well for general-purpose uses, PA66-CF20 provides superior performance for demanding industrial, automotive, and structural components requiring enhanced durability and load-bearing capacity.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.