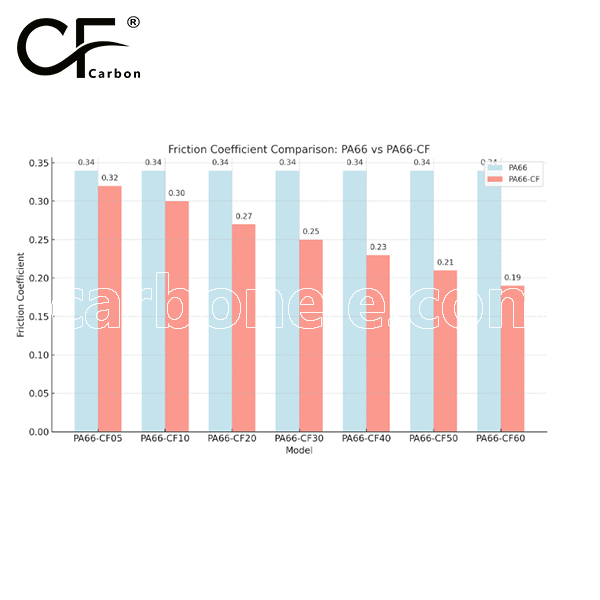

The friction coefficient of PA66-CF is significantly lower than that of unreinforced PA66, thanks to the presence of carbon fiber, which acts as a solid lubricant. While PA66 already offers decent wear resistance, the addition of carbon fiber greatly enhances its tribological performance by reducing surface friction and improving wear resistance under load and repeated motion. This makes PA66-CF especially suitable for applications involving sliding contact or dynamic mechanical stress.

PA66-LCF10 for Sale – Solve Impact Failure in Nylon Parts Fast

Discover PA66-LCF10, a high-performance nylon 66 with 10% long carbon fiber for improved mechanical strength, impact resistance, and reduced warpage.

- Model number: PA66-LCF-BCA1

- Matrix Resin: Polyamide66

- Reinforcing Filler: Carbon fiber(10%)

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PA66-LCF10 for Sale – Solve Impact Failure in Nylon Parts Fast

Upgrade your product performance with PA66-LCF10 – a long carbon fiber reinforced nylon 66 composite designed to eliminate the common failures of traditional nylon parts under mechanical stress. Whether you’re building high-precision components or structural housings, this material offers an optimal blend of toughness, stiffness, and stability.

What Is PA66-LCF10?

PA66-LCF10 is a specialized engineering-grade composite that combines the durability of nylon 66 with the added reinforcement of long carbon fibers. This combination enhances the mechanical strength and impact resistance, making it an ideal solution for demanding applications where regular polyamide materials may crack or deform.

The material features enhanced load-bearing capability, improved dimensional stability, and long-term reliability under thermal and mechanical cycling. It is tailored for manufacturers who need a superior alternative to conventional plastics.

Why Choose PA66-LCF10?

When standard nylon components fail due to impact, vibration, or thermal stress, PA66-LCF10 steps in with a higher resistance to crack propagation and part fatigue. The long carbon fiber reinforcement distributes stress more evenly across the part, maintaining structural integrity even under tough conditions.

In many industries, especially those focused on lightweight yet durable designs, PA66-LCF10 offers the advantage of performance without the drawbacks of metal or unreinforced plastics.

Key Benefits of Using PA66-LCF10

-

Improved resistance to mechanical failure

-

Enhanced rigidity and part stability over time

-

Reduced deformation under load

-

Increased design flexibility for complex shapes

-

Lower part failure rates in challenging environments

Application Scenario: Automotive Engine Mounting Bracket

Imagine an automotive part manufacturer producing engine mounting brackets from standard nylon 66. Over time, these brackets develop cracks due to engine vibration and continuous exposure to heat.

By switching to PA66-LCF10, the manufacturer solves these issues instantly. The part maintains its shape, absorbs stress efficiently, and does not require frequent replacements. This change not only improves vehicle reliability but also reduces warranty claims and maintenance costs.

The carbon fiber reinforcement helps the bracket absorb and dissipate vibrational energy, minimizing stress points and eliminating premature failures. As a result, the upgraded component becomes a long-term solution, delivering consistency across production batches.

PA66-LCF10 in Industrial Design

In industrial applications, PA66-LCF10 is often used for structural housings, enclosures, and machine supports. These parts need to withstand continuous operation, mechanical friction, and occasional impact. Traditional materials often warp or break down over time.

With PA66-LCF10, engineers can design parts with thinner walls and complex geometries without compromising performance. This opens up new possibilities in space-constrained assemblies and high-load configurations.

PA66-LCF10 for Consumer Electronics

Device designers often struggle with finding materials that offer both precision and structural strength. PA66-LCF10 is a perfect fit for internal structural frames in laptops, printers, and smart devices. It ensures long-term reliability, resists thermal deformation, and maintains part integrity even after extended use.

Moreover, the material’s natural stiffness allows it to hold tight tolerances, ensuring consistent performance and assembly compatibility throughout the device’s life cycle.

Reliable Performance Without Compromise

The value of PA66-LCF10 goes beyond mechanical strength. It offers excellent processability in injection molding, making it compatible with existing manufacturing workflows. Manufacturers benefit from easy integration, minimal tooling adjustment, and fast cycle times.

Additionally, PA66-LCF10 reduces the need for secondary reinforcements or design changes, making product development more streamlined. It supports both mass production and small batch customization with consistent quality across runs.

The Ideal Material for Engineers and Product Developers

For designers and engineers working on high-stress components, PA66-LCF10 provides peace of mind. Its robust structure and superior fatigue resistance allow for creative freedom without compromising reliability.

From automotive assemblies to industrial devices and precision consumer parts, this material ensures your products meet modern expectations for strength, durability, and stability.

Conclusion: Choose PA66-LCF10 for Next-Level Performance

If your nylon parts are cracking, warping, or failing under impact, PA66-LCF10 is the solution. Its long carbon fiber reinforcement transforms ordinary components into durable, long-lasting parts that withstand real-world challenges.

By choosing PA66-LCF10, you are investing in performance, reliability, and long-term value for your applications.

If you want to get more information about PA66-LCF10, you can visit our Youtube.

Click here to contact us.

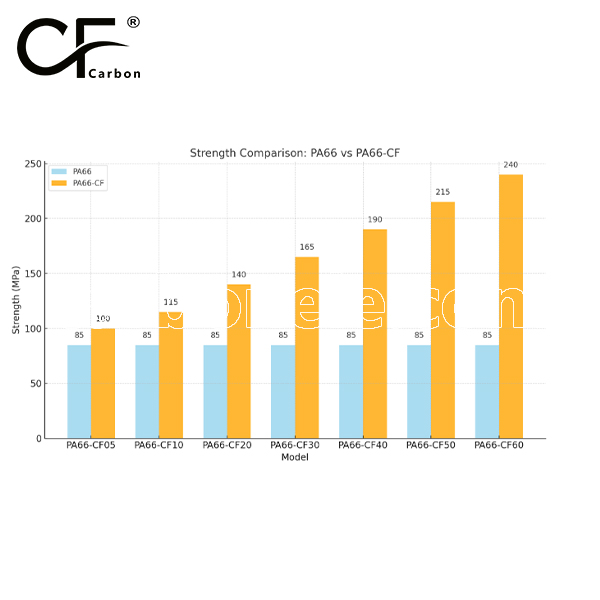

Strength between PA66 and PA66-CF

Compared to unreinforced PA66, PA66-CF (carbon fiber reinforced) offers significantly higher strength and stiffness. The addition of carbon fiber increases tensile and flexural strength, enhances dimensional stability, and reduces deformation under load. While standard PA66 provides good toughness and impact resistance, PA66-CF materials are better suited for structural and high-stress applications where superior mechanical performance is required.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.