Say Goodbye to Warping – PBT CF10 Solves Thermal Distortion

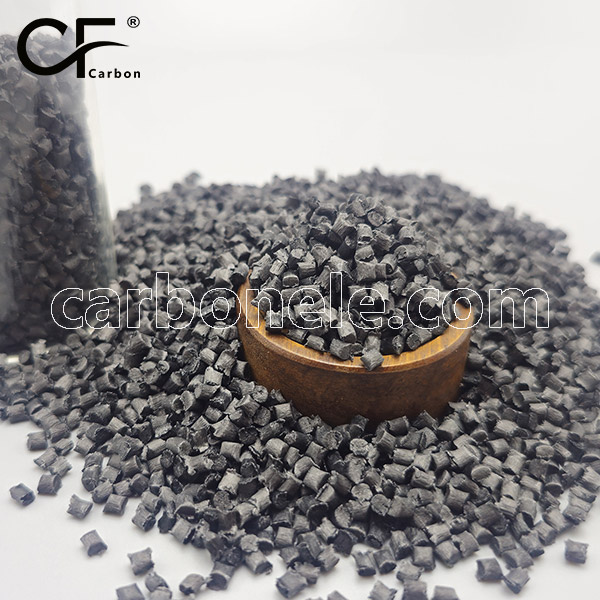

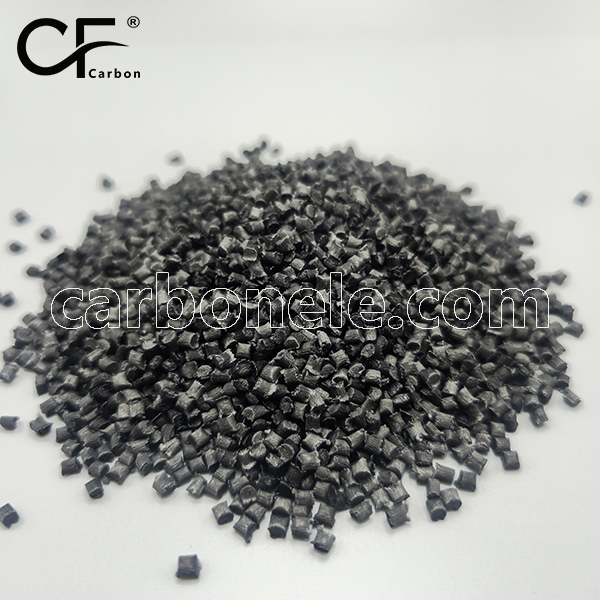

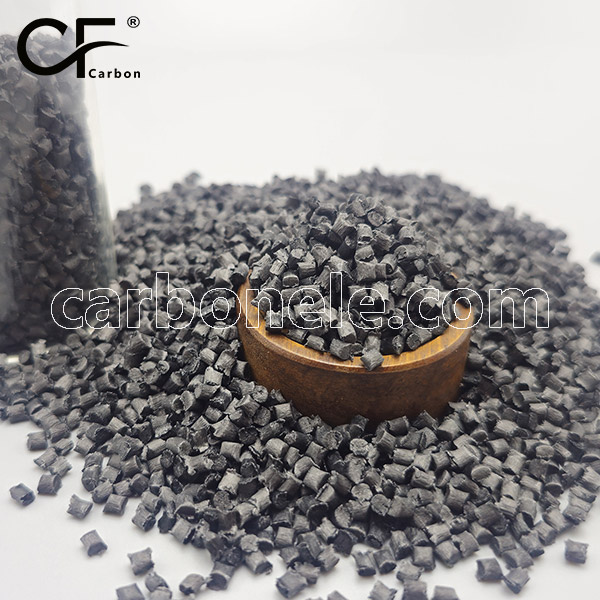

Discover PBT CF10 – a carbon fiber reinforced plastic engineered to resist warping and thermal distortion while delivering superior dimensional stability.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free samples: ≤10kg

- MOQ: 100kg

- Port: Xiamen

- Model number: PBT-CF-BCA1

- Matrix Resin: PBT

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Say Goodbye to Warping—PBT CF10 Solves Thermal Distortion

When dimensional accuracy and stability matter, you need more than just a standard thermoplastic. That’s where PBT CF10 steps in. Reinforced with carbon fiber, this high-performance composite is specifically engineered to eliminate the common issues of warping, deformation, and loss of strength under heat.

Whether you’re building precision components or complex housings, PBT CF10 ensures your parts stay true to form—every time.

What Is PBT CF10 and Why It Matters

PBT CF10 is a carbon fiber reinforced polybutylene terephthalate, a high-performance engineering thermoplastic known for its chemical resistance and mechanical strength. The addition of carbon fiber transforms standard PBT into a material that can withstand high temperatures and mechanical stress without compromising shape or performance.

If you’ve ever struggled with materials that twist, warp, or sag during cooling or under operational heat, PBT CF10 offers a dependable solution. Its superior dimensional stability makes it ideal for parts that demand precision even in thermally demanding environments.

Application Example: Automotive Sensor Housings

One of the most common real-world applications of PBT CF10 is in the production of automotive sensor housings. These components must fit precisely and function reliably while mounted near heat-generating engine parts. Traditional plastics often fail in these areas, causing alignment issues and functional errors over time.

Using PBT CF10, manufacturers have been able to mold sensor housings that maintain exact dimensions even after prolonged exposure to engine temperatures. The carbon fiber reinforcement in the material prevents heat-induced expansion and warping, ensuring that sensors remain correctly positioned and fully functional throughout their life cycle.

Key Features of PBT CF10 That Reduce Warping

Thermal Distortion Resistance

Unlike standard PBT, PBT CF10 is specially formulated to resist changes in shape and dimension when exposed to elevated temperatures. This is critical in environments where mechanical parts experience constant heat fluctuations.

Enhanced Structural Rigidity

Carbon fiber reinforcement gives PBT CF10 a notable increase in stiffness, allowing components to retain their form even under load. This makes it ideal for structural parts that require both strength and dimensional accuracy.

Superior Dimensional Stability

From mold to finished part, PBT CF10 maintains tighter tolerances with minimal shrinkage. Whether you’re working with complex geometries or tight mechanical fits, the material ensures that what you design is exactly what you get.

Advantages Over Standard PBT Materials

While traditional PBT already offers respectable heat resistance and chemical compatibility, it often falls short in environments that involve repeated thermal cycling or mechanical stress. PBT CF10 closes that gap with a balance of strength and stability rarely seen in unfilled polymers.

Its low coefficient of thermal expansion reduces the risk of misalignment in multi-material assemblies, and its increased rigidity minimizes the need for post-processing or dimensional correction. In short, PBT CF10 helps streamline manufacturing while reducing failure rates in the field.

Perfect for Complex and Demanding Applications

PBT CF10 isn’t just for automotive components. Its unique performance profile makes it suitable for a range of industries and applications, including:

-

Electrical Connectors: Keeps tight fits even after heat cycles

-

Consumer Electronics: Maintains precision in housings for small, sensitive devices

-

Industrial Machinery: Performs reliably in parts exposed to vibration and thermal load

-

3D Printed End-Use Parts: Offers professional-grade mechanical properties post-print

In all these cases, PBT CF10 proves itself a reliable choice where ordinary materials fail.

Easy Processing with Industrial Equipment

Despite its high-performance nature, PBT CF10 processes easily using standard injection molding equipment. Manufacturers don’t need to make major adjustments to existing tooling or processes, which helps reduce cost and increase production efficiency. The material also offers a smooth, uniform surface finish, improving both aesthetics and functionality.

Why Choose PBT CF10 for Your Project

When failure isn’t an option, PBT CF10 delivers. It offers the strength of carbon fiber with the versatility of thermoplastic, solving critical problems like warping, thermal distortion, and dimensional drift. With PBT CF10, you don’t have to compromise between mechanical performance and design flexibility.

Whether you’re manufacturing parts for high-heat environments, structural applications, or precision assemblies, PBT CF10 helps you move from design to reality—confidently and consistently.

Ready to Upgrade? Choose PBT CF10 Today

Say goodbye to warped parts, misaligned assemblies, and costly reworks. With PBT CF10, your designs stay sharp, your parts stay strong, and your customers stay satisfied. It’s time to make the switch to a smarter, more stable material.

If you want to get more information about ABS-CF10, you can visit our YouTube.

You can click here to contact us.

About Us

Integrating R&D, production and sales seamlessly, Carbon (Xiamen) New Material is steadfast in its commitment to providing top-notch carbon fiber reinforced thermoplastics. By relying on a highly professional R&D team, this company stands at the forefront of innovation. The R&D team is composed of experts and engineers who possess profound knowledge and extensive experience in the field. They are constantly exploring and pioneering new technologies and materials to enhance the performance and quality of the products. The modern advanced factory is equipped with state-of-the-art machinery and facilities. It adheres to strict quality control standards throughout the production process, ensuring that every product meets or exceeds industry standards. In addition to that, Carbon (Xiamen) New Material Co., Ltd. places great emphasis on meticulous pre-sales and after-sales services. The pre-sales team works closely with customers to understand their specific needs and provide tailored solutions. The after-sales service team is always ready to address any concerns or issues promptly, providing comprehensive support and ensuring customer satisfaction. Through these efforts, the company aims to create one-stop services and offer complete solutions of CFRTP products, establishing a strong reputation and trust in the market.

Advanced Laboratory Equipment

The advanced laboratory equipment of Carbon (Xiamen) New Material Co., Ltd. plays a crucial role in its research and development and quality control processes. These advanced laboratory equipment cover multiple fields and functions. For example, high-precision material analysis instruments can conduct precise composition analysis of raw materials and finished products to ensure that the products meet strict quality standards. There are also advanced mechanical property testing equipment used to evaluate key performance indicators such as the strength, toughness and durability of materials. Thermal performance testing equipment can help researchers understand the behavior of materials under different temperature conditions, which is essential for developing products that adapt to various environments. In addition, microstructure analysis equipment enables scientists to closely observe the microstructure of materials, providing a strong basis for optimizing material performance. These advanced laboratory equipment not only improve the R&D efficiency and product quality, but also provide strong support for Carbon (Xiamen) New Material Co., Ltd. to maintain a leading position in the highly competitive market. They are an important guarantee for the company's continuous innovation and development, helping the company provide customers with better and more reliable new material solutions.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.