PBT CF20 Door Panel, Silent & Durable

Discover PBT CF20, the advanced carbon fiber-reinforced composite for durable, silent automotive door panels. Perfect for reducing noise, resisting wear, and ensuring long-term stability—ideal for premium interiors. Elevate your vehicle’s comfort and performance with PBT CF20.

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free samples: ≤10kg

- MOQ: 100kg

- Port: Xiamen

- Model number: PBT-CF-BCA2

- Matrix Resin: PBT

- Reinforcing Filler: Carbon fiber

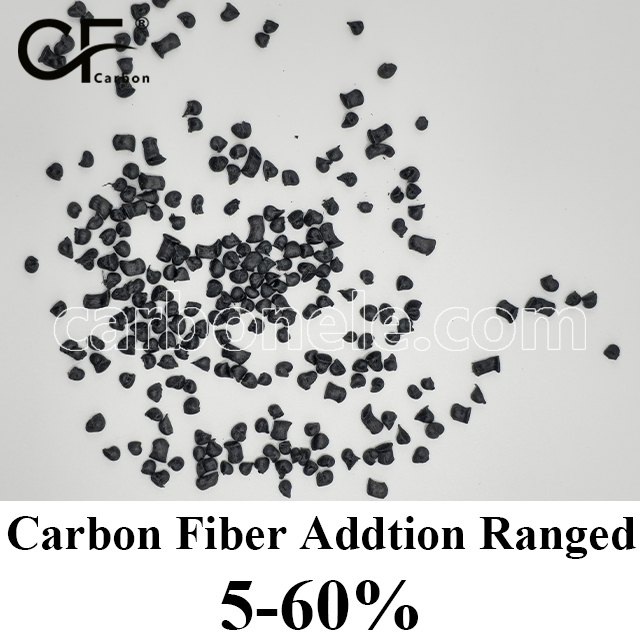

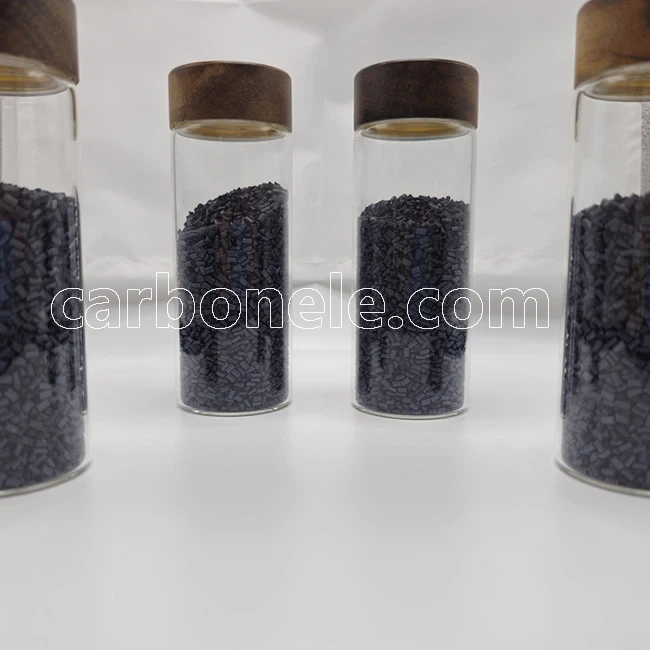

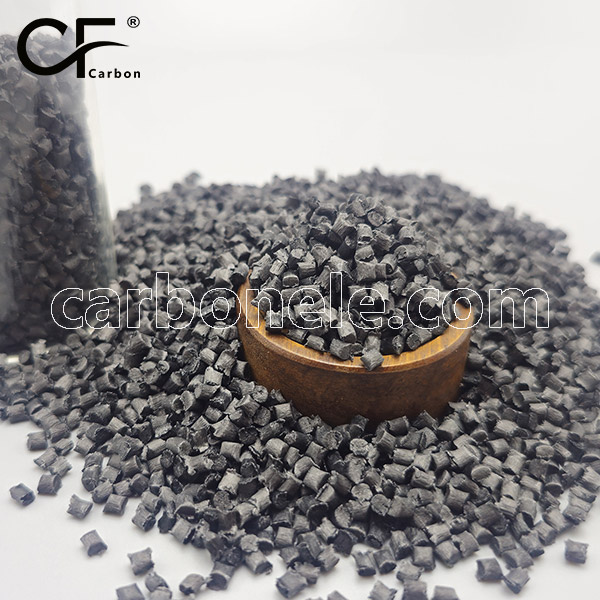

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PBT CF20 Door Panel, Silent & Durable

Introduction to PBT CF20

PBT CF20 is an advanced composite that merges the proven stability of polybutylene terephthalate with the high-strength reinforcement of carbon fiber.

The result is a material that delivers both silent operation and exceptional durability—two essential qualities for automotive interior applications.

When applied to a door panel, PBT CF20 enhances not only the mechanical performance but also the overall driving experience. Its ability to reduce vibration and noise ensures a quiet cabin environment, while its strength and stability guarantee long-term structural integrity.

This combination positions PBT CF20 as a premium choice for manufacturers seeking to elevate both functionality and comfort in vehicle interiors.

Why PBT CF20 Excels in Door Panel Applications

Silent Performance in Motion

Natural Vibration Damping

The inherent properties of PBT CF20 allow it to absorb and dampen vibrations, reducing noise transfer from the outside environment into the cabin. This makes it ideal for use in door panels, where sound insulation directly affects passenger comfort.

Minimized Rattles and Creaks

Door panels endure constant opening, closing, and movement. PBT CF20 maintains a precise fit over time, preventing the looseness that can cause unwanted noises.

Exceptional Durability

Resistance to Daily Wear

Automotive door panels face frequent contact from passengers, cargo, and even environmental factors. PBT CF20 resists scratches, dents, and surface degradation, ensuring the panel remains visually appealing.

Stability Across Conditions

Temperature changes, humidity, and sunlight exposure can compromise some materials. PBT CF20 remains dimensionally stable, retaining its shape and alignment regardless of seasonal changes.

Real-World Application – Driver’s Side Door Panel

The driver’s side door panel is one of the most frequently used components in a vehicle. It must withstand constant handling, house controls for windows and mirrors, and still maintain a quiet and refined presence.

PBT CF20’s strength allows for secure mounting of functional elements without risk of cracking or deformation. At the same time, its carbon fiber reinforcement ensures the panel remains lightweight, supporting overall vehicle efficiency.

The result is a component that feels solid to the touch, performs reliably, and contributes to the premium feel of the cabin.

Processing Advantages of PBT CF20

Compatibility with Automotive Manufacturing

Injection Molding Efficiency

PBT CF20 is well-suited for injection molding, allowing manufacturers to produce complex, precision-fit panels with high repeatability. This ensures every door panel meets strict dimensional requirements.

Surface Finish Quality

From textured surfaces that hide fingerprints to smooth finishes for luxury designs, PBT CF20 offers flexibility in aesthetic treatment without compromising performance.

Design Freedom and Integration

Supporting Complex Door Architectures

Modern vehicle doors integrate speakers, lighting, switches, and storage pockets. PBT CF20 enables the creation of integrated designs without sacrificing strength or acoustic performance.

Enhancing Passenger Experience

A well-designed door panel made from PBT CF20 contributes to a more pleasant driving environment. Passengers benefit from reduced noise, a premium tactile feel, and the reassurance of long-term durability.

Long-Term Reliability

Maintaining Performance Over Years

PBT CF20 ensures that door panels retain their original fit, function, and appearance even after years of regular use. Its resilience against environmental stressors protects both the structural and aesthetic qualities.

Sustainable Choice

While delivering exceptional performance, PBT CF20 also supports sustainability goals by enabling lightweight construction, which can help improve fuel efficiency in conventional vehicles and extend battery range in electric vehicles.

Conclusion – PBT CF20 for the Future of Automotive Interiors

PBT CF20 is more than just a material; it is a solution for creating automotive door panels that are silent, durable, and refined. Its unique combination of carbon fiber strength and PBT stability meets the needs of modern vehicles, where performance and passenger comfort go hand in hand.

By choosing PBT CF20, manufacturers can deliver interiors that stand the test of time, ensuring every journey is as quiet and enjoyable as the first.

If you want to get more information about ABS-CF10, you can visit our YouTube.

You can click here to contact us.

About Us

Integrating R&D, production and sales seamlessly, Carbon (Xiamen) New Material is steadfast in its commitment to providing top-notch carbon fiber reinforced thermoplastics. By relying on a highly professional R&D team, this company stands at the forefront of innovation. The R&D team is composed of experts and engineers who possess profound knowledge and extensive experience in the field. They are constantly exploring and pioneering new technologies and materials to enhance the performance and quality of the products. The modern advanced factory is equipped with state-of-the-art machinery and facilities. It adheres to strict quality control standards throughout the production process, ensuring that every product meets or exceeds industry standards. In addition to that, Carbon (Xiamen) New Material Co., Ltd. places great emphasis on meticulous pre-sales and after-sales services. The pre-sales team works closely with customers to understand their specific needs and provide tailored solutions. The after-sales service team is always ready to address any concerns or issues promptly, providing comprehensive support and ensuring customer satisfaction. Through these efforts, the company aims to create one-stop services and offer complete solutions of CFRTP products, establishing a strong reputation and trust in the market.

Advanced Laboratory Equipment

The advanced laboratory equipment of Carbon (Xiamen) New Material Co., Ltd. plays a crucial role in its research and development and quality control processes. These advanced laboratory equipment cover multiple fields and functions. For example, high-precision material analysis instruments can conduct precise composition analysis of raw materials and finished products to ensure that the products meet strict quality standards. There are also advanced mechanical property testing equipment used to evaluate key performance indicators such as the strength, toughness and durability of materials. Thermal performance testing equipment can help researchers understand the behavior of materials under different temperature conditions, which is essential for developing products that adapt to various environments. In addition, microstructure analysis equipment enables scientists to closely observe the microstructure of materials, providing a strong basis for optimizing material performance. These advanced laboratory equipment not only improve the R&D efficiency and product quality, but also provide strong support for Carbon (Xiamen) New Material Co., Ltd. to maintain a leading position in the highly competitive market. They are an important guarantee for the company's continuous innovation and development, helping the company provide customers with better and more reliable new material solutions.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.