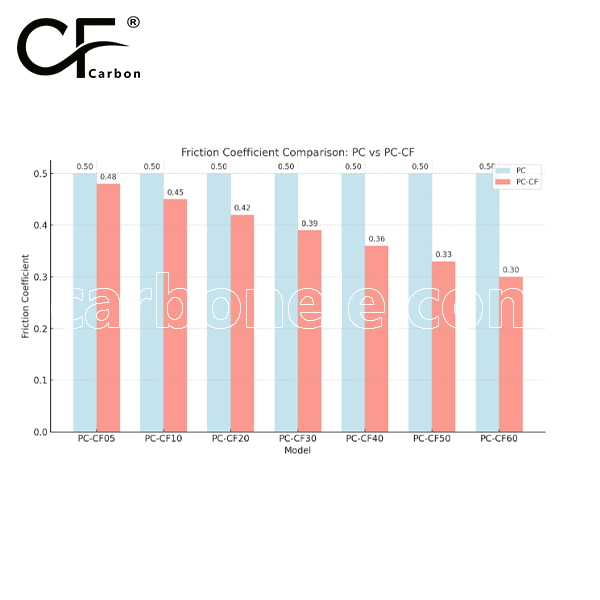

The friction coefficient of PC-CF is lower than that of unreinforced PC due to the presence of carbon fiber, which enhances wear resistance and reduces surface friction. Standard PC has a relatively high friction coefficient, making it prone to surface wear in applications with repeated contact or sliding motion. The addition of carbon fiber in PC-CF improves tribological performance, lowering friction and reducing material degradation over time. This makes PC-CF a better choice for applications requiring lower friction, improved wear resistance, and higher durability under mechanical stress.

PC-CF30 Is 3X Stiffer Than Standard PC—Here’s Why That Matters

Discover the advantages of PC-CF30, a carbon fiber reinforced polycarbonate with superior stiffness and heat resistance. Ideal for automotive housings, industrial enclosures, and structural plastic parts.

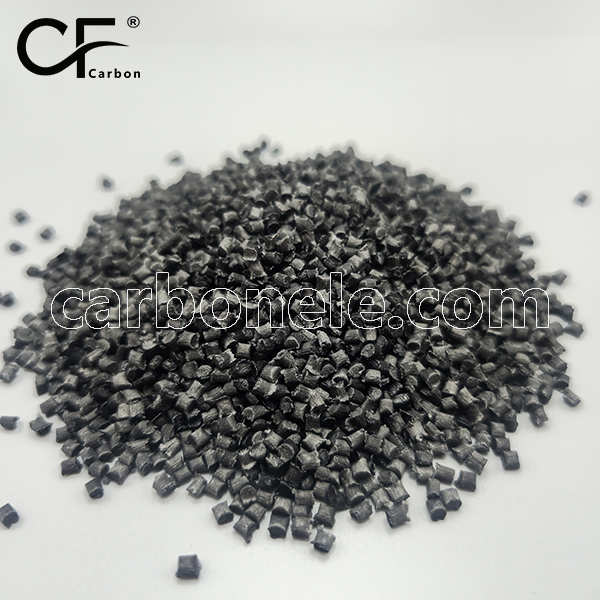

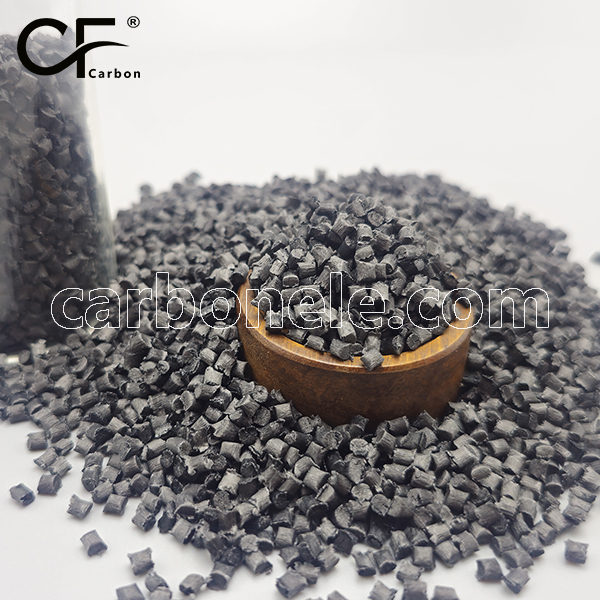

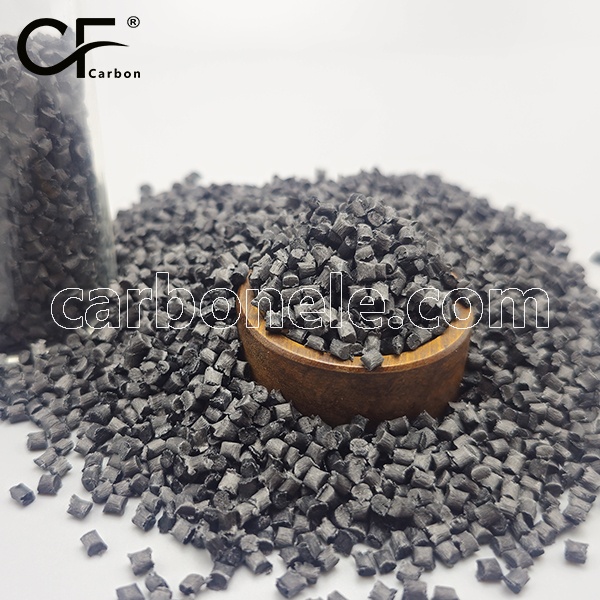

- Model number: PC-CF-BCA3

- Matrix Resin: Polycarbonate (PC)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PC-CF30 Is 3X Stiffer Than Standard PC—Here’s Why That Matters

What Makes PC-CF30 a Game-Changer in Modern Manufacturing

When durability, heat resistance, and long-term reliability are non-negotiable, manufacturers turn to materials that do more than just “get the job done.” That’s where PC-CF30 enters the picture. Engineered through the precise fusion of polycarbonate and carbon fiber, PC-CF30 delivers outstanding structural performance that exceeds traditional thermoplastics in demanding environments.

Whether you’re designing for extreme heat, mechanical pressure, or structural stability, PC-CF30 stands out as a material of choice. In this product detail guide, we will walk you through its advantages, how it performs in real-life use, and why industries are adopting it at scale.

PC-CF30 Application Scenario: Automotive LED Headlamp Housing

Imagine a vehicle operating in hot climates where engine temperatures spike daily. Standard PC materials used in LED housings tend to warp, deform, or weaken over time. When a leading automotive supplier switched to PC-CF30, the result was clear: no visible change in housing integrity after long-term use.

Thanks to its enhanced structure, PC-CF30 was able to retain form, prevent mounting misalignments, and maintain reliable optical positioning in the LED system — all without needing design overhauls or new tools.

This is just one example of how PC-CF30 solves real-world design problems.

Why Choose PC-CF30 Over Standard Polycarbonate

Material Composition Enhances Structural Stability

At its core, PC-CF30 is a blend of high-quality polycarbonate and carbon fiber reinforcement. This combination creates a tightly bonded matrix that improves rigidity without adding significant weight.

Unlike standard PC, which can bend or soften in harsh conditions, PC-CF30 retains its mechanical properties in more aggressive thermal and mechanical environments.

Ideal for Functional and Structural Components

PC-CF30 is commonly used in:

-

Automotive housings

-

Drone and UAV shells

-

Electronics and device enclosures

-

Industrial brackets and gears

-

Tool handles and power equipment covers

Wherever strength and heat resistance intersect, PC-CF30 provides the ideal solution.

PC-CF30 Processing and Manufacturability

Compatible with Existing Injection Molding Systems

One of the best advantages of PC-CF30 is its processing versatility. It can be molded using the same tools and machines as standard PC, reducing the need for re-tooling or production downtime.

Smooth Surface, Matte Finish

Despite its rigidity, PC-CF30 offers a surface finish that balances appearance and functionality. The result is a matte, non-reflective surface that resists scratches and wears gracefully over time — perfect for visible components.

PC-CF30 Is Built for Long-Term Use

Stable Under Long-Term Load

PC-CF30 resists creep and maintains dimensional accuracy, making it suitable for structural components that must hold shape over long periods. This property is critical in applications such as sensor brackets, structural clips, or mounting fixtures.

Vibration and Impact Tolerant

For environments with high vibration or impact exposure — such as under-hood components or drones — PC-CF30 offers the balance of stiffness and shock absorption needed to extend the product’s lifetime.

Post-Sale Support and Material Confidence

Full Support on Molding Parameters and Customization

We offer post-purchase guidance on molding conditions, design tweaks, and fiber loading customization. Whether you’re working with complex part geometries or looking for specific color finishes, PC-CF30 is flexible enough to meet those demands.

Quality Assurance in Every Shipment

Each batch of PC-CF30 is traceable and quality verified, offering manufacturers peace of mind. Our materials are tested for batch consistency and mechanical reliability before shipment.

Why PC-CF30 Sets the Standard for Engineering Composites

PC-CF30 is not just an alternative — it’s an upgrade. From enhanced surface properties to improved structural load capacity, this material is proving indispensable across industries. As manufacturers seek materials that are as functional as they are reliable, PC-CF30 leads with a balance of form and function.

Industry Confidence and Expert Perspective

What Engineers Are Saying

Engineers working with high-performance parts are increasingly turning to carbon fiber composites to reduce weight without compromising strength.

“PC-CF30 has become our go-to for heat-exposed enclosures. We don’t see the same warpage issues as we used to with traditional PC.”

— Materials Engineer, OEM Electronics Firm

“It molds clean, holds tight tolerances, and gives us the stiffness our clients demand.”

— Design Consultant, Automotive Plastics Solutions

Final Thoughts – Why This Material Matters

When failure is not an option — in automotive systems, consumer electronics, or structural components — PC-CF30 delivers the properties that matter most.

It is not just stiffer than standard PC. It is smarter, tougher, and better engineered for real-world demands. Make the switch to PC-CF30 and experience the next generation of carbon-reinforced thermoplastics.

If you want to get more information about PC-CF20, you can visit our Youtube.

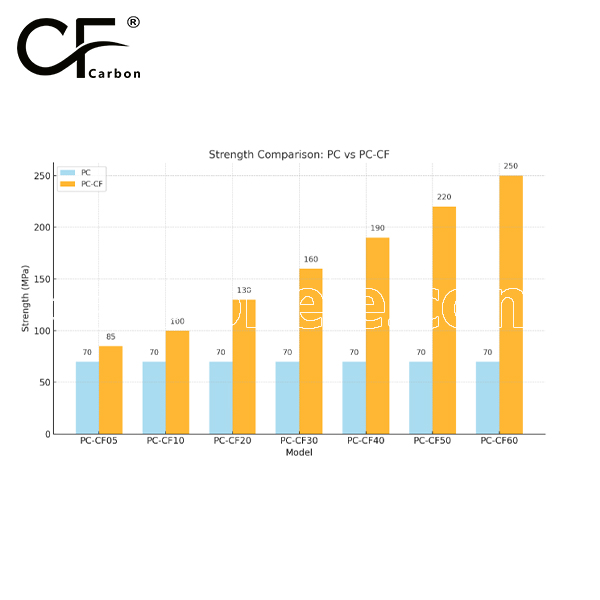

Strength between PC and PC-CF

The strength of PC-CF is higher than unreinforced PC due to the addition of carbon fiber, which enhances tensile and flexural strength, stiffness, and dimensional stability. While standard PC is known for its high impact resistance and toughness, it lacks the rigidity needed for structural applications. PC-CF, with carbon fiber reinforcement, significantly improves stiffness and load-bearing capacity while maintaining good impact resistance. However, higher carbon fiber content may slightly reduce ductility compared to pure PC. This makes PC-CF an ideal choice for applications requiring greater strength, wear resistance, and stability under mechanical stress.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.