Polypropylene reinforced carbon fiber PP-CF10

PP-CF10 is an advanced composite material combining polypropylene with 10% carbon fiber reinforcement, delivering superior strength, stiffness, and wear resistance. With enhanced tensile and flexural strength, improved thermal stability (HDT ~120°C), and low moisture absorption, it is ideal for automotive, industrial, and structural applications. This lightweight yet durable material maintains excellent chemical resistance and is easily processed via injection molding or extrusion. PP-CF10 offers a cost-effective, high-performance solution for demanding environments where weight reduction and durability are critical. Suitable for CNC machining, it’s perfect for prototypes, functional parts, and end-use components.

- Model number: PP-CF-BAC1

- Matrix Resin: Polypropylene

- Reinforcing Filler: Carbon fiber(10%)

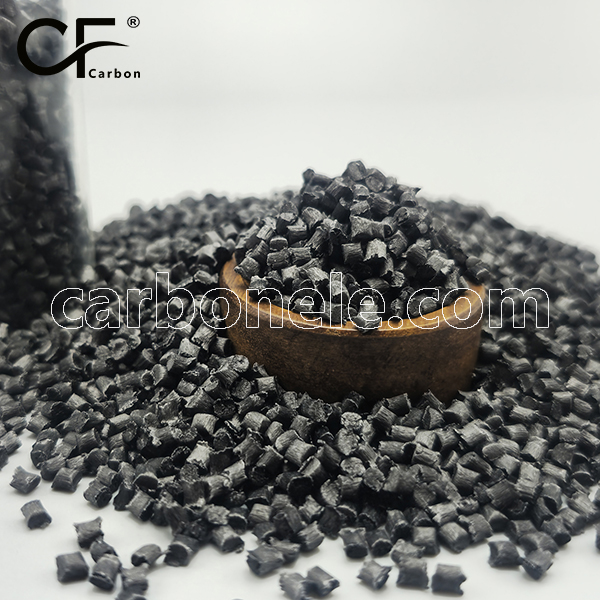

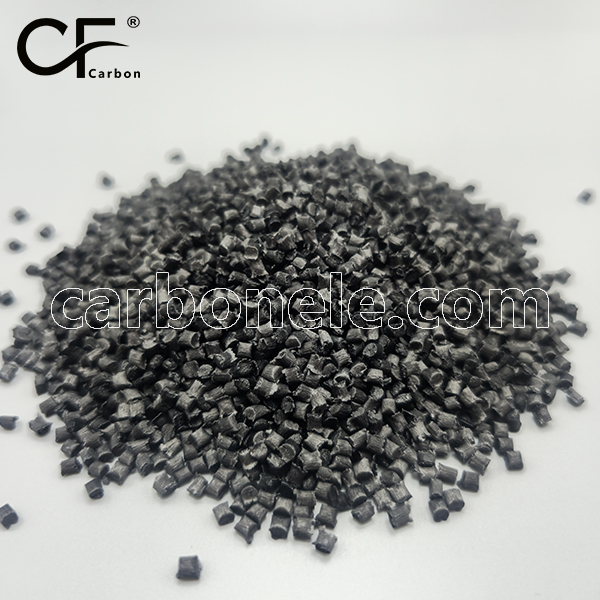

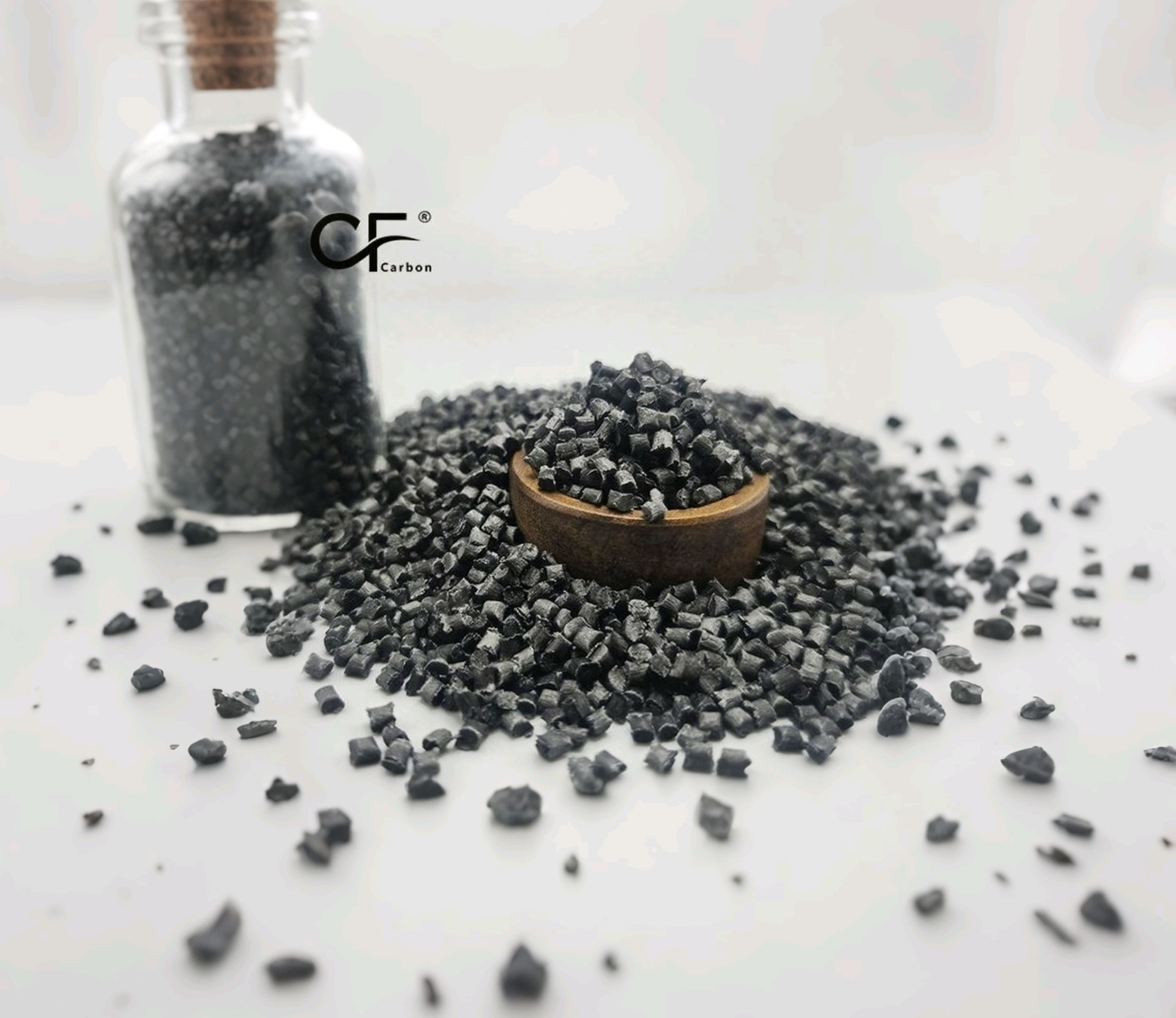

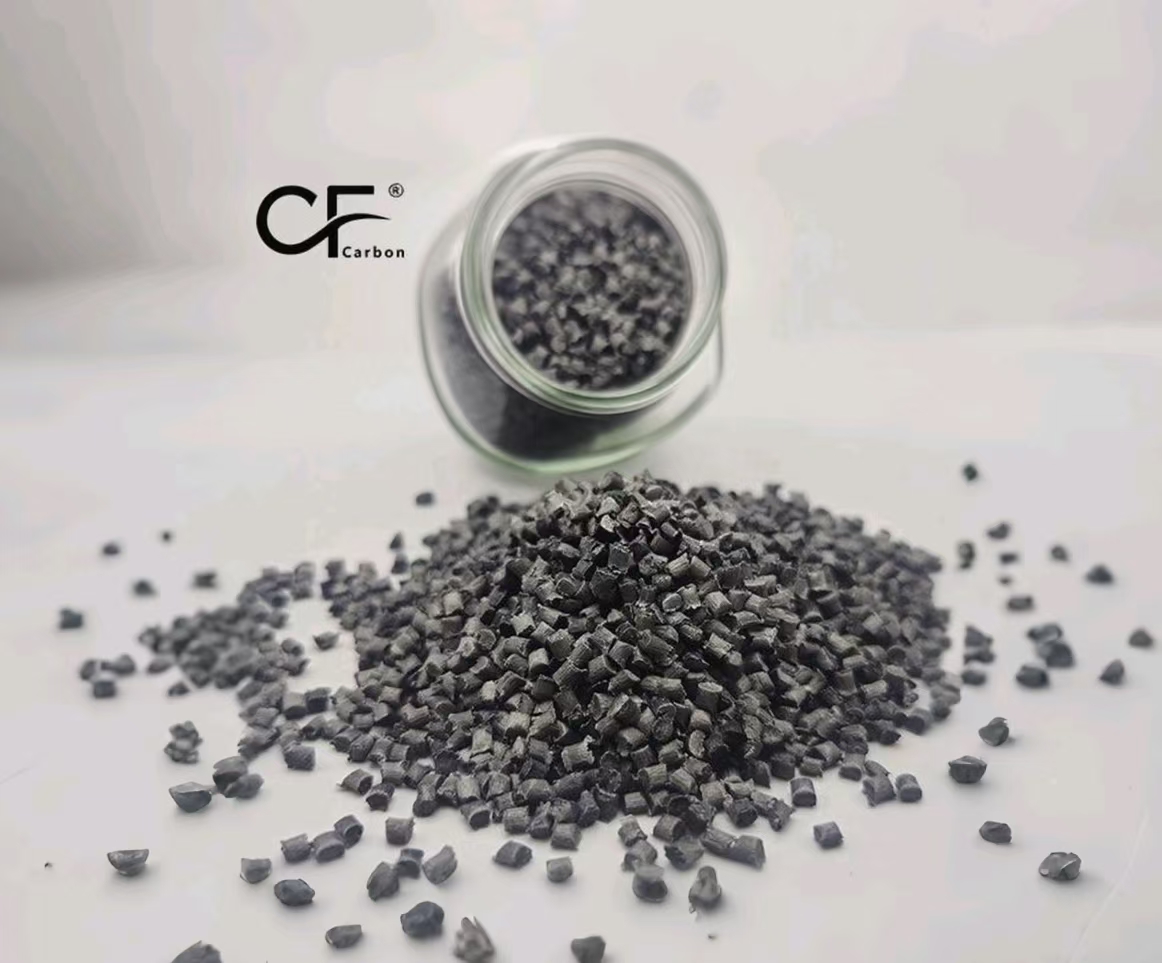

- Appearance: Granules

- Application: Automotive parts,Drone frames,Robotics components,etc.

- Packaging: 25kgs/bag

PP-CF10 Carbon Fiber Reinforced Polypropylene Composite Sheet – Industrial Grade Lightweight Material for High Performance Applications

Product Introduction

The PP-CF10 is an innovative carbon fiber reinforced polypropylene composite sheet that represents the next generation of lightweight structural materials. Engineered for demanding industrial applications, this advanced composite combines the exceptional mechanical properties of carbon fiber with the versatility and cost-effectiveness of polypropylene. Our PP-CF10 sheets deliver superior performance-to-weight ratios while maintaining excellent workability and environmental resistance.

Key Features and Benefits

Unmatched Strength-to-Weight Ratio

The PP-CF10 composite sheet offers a perfect balance between lightweight characteristics and structural integrity. With a density significantly lower than aluminum (approximately 1.3 g/cm³), our material provides comparable strength while reducing component weight by up to 50% compared to traditional metal alternatives. This weight reduction translates to improved energy efficiency and performance in moving applications.

Exceptional Durability and Impact Resistance

Our proprietary manufacturing process ensures optimal fiber-matrix bonding, resulting in outstanding impact resistance and fatigue performance. The PP-CF10 maintains its structural properties under repeated stress cycles, making it ideal for dynamic load applications. The material’s vibration damping characteristics further enhance its suitability for precision applications.

Chemical and Environmental Resistance

Unlike metal alternatives, the PP-CF10 is completely resistant to corrosion from moisture, chemicals, and salt spray. The polypropylene matrix provides excellent resistance to acids, alkalis, and solvents, ensuring long-term performance in harsh industrial environments. UV-stabilized formulations are available for outdoor applications.

Thermal and Electrical Properties

The composite exhibits low thermal conductivity (0.25-0.35 W/m·K), making it suitable for thermal insulation applications. Its non-conductive nature (volume resistivity >10¹⁵ Ω·cm) makes it perfect for electrical insulation components. The material maintains dimensional stability across a wide temperature range (-40°C to +120°C continuous, with short-term peaks to 150°C).

Manufacturing and Processing Advantages

The PP-CF10 can be easily machined using conventional workshop tools without requiring specialized equipment. It demonstrates excellent machinability characteristics:

-

Clean cutting with minimal fraying

-

No delamination during drilling operations

-

Excellent surface finish quality

-

Compatibility with CNC machining, laser cutting, and water jet cutting

Technical Specifications

-

Material Composition: 60% carbon fiber, 40% polypropylene matrix

-

Available Thickness: 0.5mm to 25mm (standard sizes), custom thicknesses available

-

Tensile Strength: 350-550 MPa (depending on fiber orientation)

-

Flexural Strength: 400-600 MPa

-

Compressive Strength: 300-450 MPa

-

Coefficient of Thermal Expansion: 5-8 × 10⁻⁶/°C (parallel to fiber direction)

-

Flammability Rating: UL94 HB

Industry Applications

Automotive and Transportation

-

Lightweight structural components

-

Interior trim panels

-

Battery enclosures for electric vehicles

-

Underbody protection panels

Aerospace and UAV

-

Drone frames and arms

-

Satellite components

-

Aircraft interior panels

-

Reinforcement structures

Industrial Equipment

-

Machine guards and covers

-

Conveyor system components

-

Robotic end-effectors

-

Process equipment liners

Renewable Energy

-

Wind turbine components

-

Solar panel support structures

-

Hydroelectric system parts

Consumer and Specialty Applications

-

High-performance sports equipment

-

Medical device components

-

Audio equipment housings

-

Protective gear and armor

Quality Assurance and Compliance

All PP-CF10 composite sheets undergo rigorous quality control testing, including:

-

Batch testing for mechanical properties

-

Dimensional accuracy verification

-

Surface quality inspection

-

Moisture absorption testing

The material meets relevant industry standards for composite materials and can be supplied with full material certification upon request.

Customization Options

We offer comprehensive customization services:

-

Custom sizing and thickness profiles

-

Alternative fiber orientations (unidirectional, bidirectional, quasi-isotropic)

-

Surface treatments and finishes

-

Pre-cut kits and machined components

-

Color options (black standard, other colors available)

Environmental Considerations

The PP-CF10 is a more sustainable alternative to traditional materials:

-

Lower energy consumption in production compared to metals

-

Fully recyclable at end of life

-

Reduced transportation energy due to lightweight nature

-

Longer service life reduces replacement frequency

Why Choose Our PP-CF10 Composite?

-

15+ years experience in advanced composite manufacturing

-

In-house R&D for continuous product improvement

-

Short lead times and flexible minimum order quantities

-

Technical support and engineering consultation

-

Global shipping and logistics support

If you want to get more information about PP-CF10, you can visit our Youtube.

Click here to contact us.

PP-CF10 High-Performance Composite Material - Unleashing New Possibilities for Industrial Applications

PP-CF10 is a composite material combining polypropylene with carbon fibers, offering both high strength and low specific gravity. Through specialized processing technology, the product achieves bending resistance three times that of conventional materials, along with excellent chemical corrosion resistance. Ideal for aerospace components and high-end machinery manufacturing applications. The modular design facilitates quick installation, effectively reducing maintenance costs and production cycles.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.