PP-CF20 Thin Carbon Sheet – 1mm Precision, Super Durable!

- Model number: PP-CF-BAC2

- Matrix Resin: Polypropylene (PP)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Introduction to PP-CF20 and Its Role in Modern Engineering

PP-CF20 represents a new level of performance for thin yet durable carbon-reinforced polypropylene sheets. Engineered for applications where strength, dimensional stability, and reduced weight are essential, it delivers outstanding reliability across a wide range of demanding environments. The integration of carbon fiber into the polypropylene matrix enhances mechanical performance without sacrificing the inherent benefits of the base polymer.

The result is a material that offers a unique combination of stiffness, resilience, and adaptability. It is particularly well-suited for precision sheet formats, making it an ideal choice for industries that require exact dimensions and consistent surface quality. Its performance characteristics enable designers and engineers to replace heavier traditional materials while improving component functionality.

The Core Advantages of PP-CF20 Thin Carbon Sheet

Lightweight Strength

One of the defining features of PP-CF20 is its ability to provide high structural performance at a fraction of the weight of metals. This lightweight nature makes it an appealing option for industries seeking to reduce overall component mass without compromising on mechanical stability.

Exceptional Dimensional Accuracy

When manufactured as thin carbon sheets, PP-CF20 maintains remarkable flatness and dimensional precision. This stability is essential for components that must fit seamlessly within complex assemblies or serve as exact substrates for further processing.

Why PP-CF20 Excels Over Alternative Materials

Improved Design Flexibility

Compared to metals or unreinforced plastics, PP-CF20 offers greater adaptability during manufacturing. Its combination of stiffness and formability allows it to be cut, shaped, or integrated into larger assemblies without loss of performance.

Resistance to Corrosive Environments

Carbon fiber reinforcement combined with polypropylene’s inherent resistance to moisture and many chemicals means that PP-CF20 can endure environments that would degrade other materials. This property makes it suitable for both indoor and outdoor applications.

Enhanced Aesthetic Appeal

Beyond performance, PP-CF20 sheets offer a sleek, professional finish. This appearance can be advantageous in products where visible surfaces contribute to overall product quality perception.

Application Example: PP-CF20 in Precision Drone Components

A strong example of PP-CF20 in action is its use in precision drone body panels. Drones require lightweight structural elements that also resist flexing under aerodynamic loads.

Functional Benefits in Drone Manufacturing

Using PP-CF20 thin carbon sheets in drone panels allows manufacturers to achieve exceptional flight stability. The material’s strength prevents unwanted vibrations and flexing, leading to smoother operation and longer component lifespan.

Efficiency and Endurance

Drone panels made from PP-CF20 maintain their performance over repeated use in varying environmental conditions. This ensures reliability for both recreational and professional drone operators who require consistent performance.

Manufacturing and Processing Advantages

Cutting and Shaping Precision

PP-CF20 thin sheets can be machined, laser-cut, or shaped with high accuracy, enabling detailed part designs. This versatility supports both prototyping and large-scale production runs.

Consistency in Thickness and Quality

Each PP-CF20 sheet can be produced with precise thickness tolerances, ensuring uniformity across batches. This consistency is critical for applications where sheet thickness directly affects performance.

Integration with Composite Structures

PP-CF20 bonds effectively with other materials, making it suitable for multi-layered composite constructions. This opens possibilities for hybrid material designs that leverage different properties in a single part.

Long-Term Stability and Reliability

Performance Under Thermal Stress

PP-CF20 maintains its structural integrity across a wide range of temperatures, preventing warping or distortion during service. This stability is a key advantage for components exposed to fluctuating heat conditions.

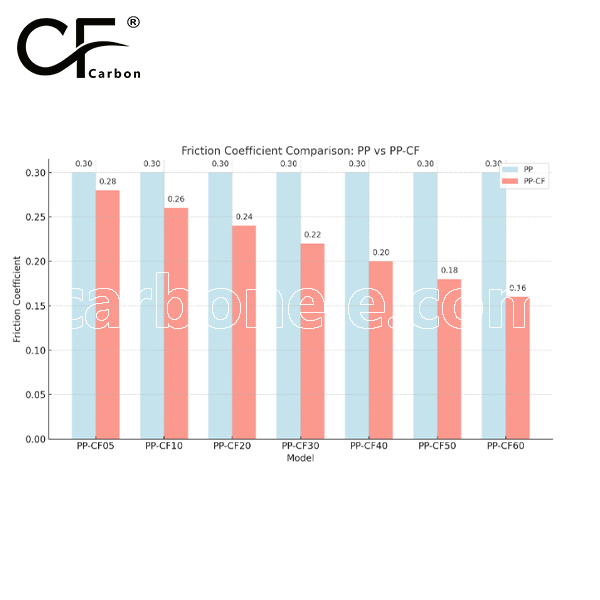

Resistance to Wear and Tear

In thin sheet applications, surface integrity is crucial. PP-CF20’s reinforced composition ensures surfaces remain intact and functional even after prolonged use.

Sustainability and Resource Efficiency

Because PP-CF20 is both durable and lightweight, its use can contribute to more sustainable designs. Lower material weight reduces energy consumption during transportation, while its longevity minimizes replacement needs.

The Future Potential of PP-CF20

With increasing demand for high-performance lightweight materials, PP-CF20 is positioned to see broader adoption across industries such as consumer electronics, transportation, and renewable energy. Innovations in sheet production and finishing techniques will continue to expand its capabilities, enabling even more specialized uses.

Conclusion

PP-CF20 thin carbon sheet offers an unmatched balance of precision, durability, and design versatility. Whether used in aerospace-inspired applications like drones or in industrial settings where dimensional accuracy is critical, it delivers consistent performance and long-term reliability. By combining the strength of carbon fiber with the resilience of polypropylene, it redefines what thin sheet materials can achieve in modern manufacturing.

If you want to get more information about PP-CF20, you can visit our YouTube.

Click here to contact us.

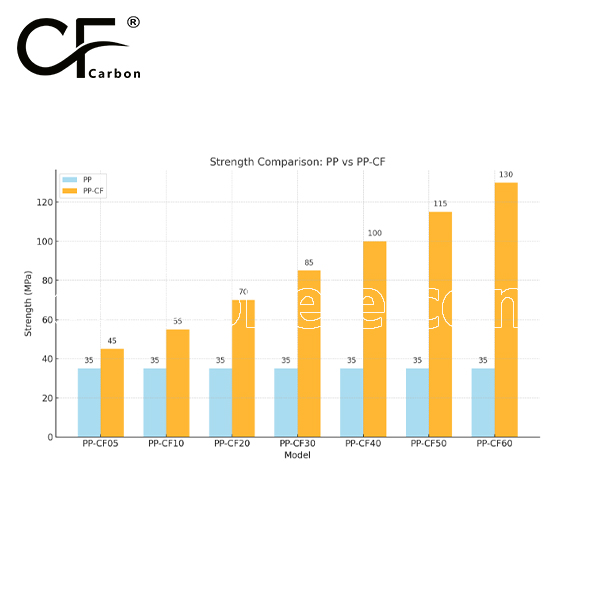

Strength between PP and PP-CF

PP-CF exhibits significantly higher strength and stiffness compared to unreinforced PP due to the addition of carbon fiber reinforcement. While standard polypropylene (PP) is known for its flexibility and impact resistance, it lacks the rigidity and load bearing capacity required for high-performance applications. In contrast, PP-CF enhances tensile strength, flexural modulus, and dimensional stability, making it more resistant to deformation under mechanical stress. This improved performance allows PP-CF to be used in applications where higher strength-to-weight ratio and structural integrity are critical.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.