PP-LCF10 Drone Structural Material

- Model number: PP-LCF-BAC1

- Matrix Resin: Polypropylene

- Reinforcing Filler: Carbon fiber(10%)

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PP-LCF10 Long Carbon Fiber Reinforced Polypropylene :

PP-LCF10 is an advanced composite material incorporating 10% long carbon fiber (LCF) reinforcement within a polypropylene (PP) matrix. Utilizing proprietary fiber dispersion technology, this material delivers exceptional strength-to-weight ratio while maintaining excellent processability – making it the ideal metal replacement solution for automotive, aerospace, and industrial applications.

Key Specifications

Basic Properties

1. Density: 1.12 g/cm³ (58% lighter than aluminum)

2.Fiber Length: 6-12mm (ASTM D792 compliant)

3. Standard Color: Black (custom gray/natural available)

Environmental Resistance

1.Operating Temp: -40°C to +130°C (peak 150°C)

2. Chemical Resistance: Passes ASTM D543 acid/alkali tests

3.Humidity Aging: >90% property retention after 1000h

Competitive Advantages

-

Weight & Cost Reduction

-

40% weight savings in automotive front-end modules

-

20% lighter drone frames for extended flight time

-

Design Flexibility

• Suitable for injection/compression molding (min. wall thickness 1.2mm)

• Material-structure-process integration support -

Tailored Performance

Customizable options:

-

Isotropic version (random fiber orientation)

-

Directional reinforcement (unidirectional fiber)

-

Sustainability

• Contains 30% recycled PP (certificates available)

• 80% lower production energy vs. metals -

Rapid Delivery

• Stock available in Asia/Europe warehouses (3-5 business days)

• Free samples for new customers

Applications

Automotive Applications

New Energy Vehicle Battery Enclosure:

As electric vehicles demand both lightweighting and enhanced safety, traditional metal battery enclosures (typically steel/aluminum) face critical challenges including excessive weight (reducing range), high costs, and corrosion susceptibility. PP-LCF10 emerges as the optimal alternative, leveraging its exceptional lightweight properties, high strength-to-weight ratio, and chemical resistance.

Application Details of PP-LCF10 in Battery Housings

1. Weight Reduction Performance

-

Traditional Solution: Aluminum alloy housing (density: 2.7 g/cm³)

-

PP-LCF10 Solution: Density as low as 1.12 g/cm³

-

Result: Achieves 45% weight reduction (e.g., from 8.5kg to 4.7kg), improving vehicle range by 3-5%.

2. Mechanical Performance Optimization

-

Stiffness: Flexural modulus of 7.2 GPa, exceeding industry standards (>5 GPa) for battery pack deformation resistance.

-

Impact Resistance: Certified to ECE R100 safety standards, capable of withstanding 6 kJ side collisions.

-

Integrated Design: Enables single-step injection molding of complex structures, reducing assembly parts by 20%.

3. Functional Integration Advantages

-

Thermal Management: Thermal conductivity (0.8 W/mK) outperforms standard PP, allowing embedded cooling channels.

-

EMI Shielding: Conductive carbon fiber (surface resistance <10⁴Ω) minimizes electromagnetic interference (EMI).

-

Corrosion Resistance: Passes 1000-hour salt spray testing (far exceeding the 500-hour lifespan of metal housings).

If you want to get more information about PP-LCF10, you can visit our Youtube.

Click here to contact us.

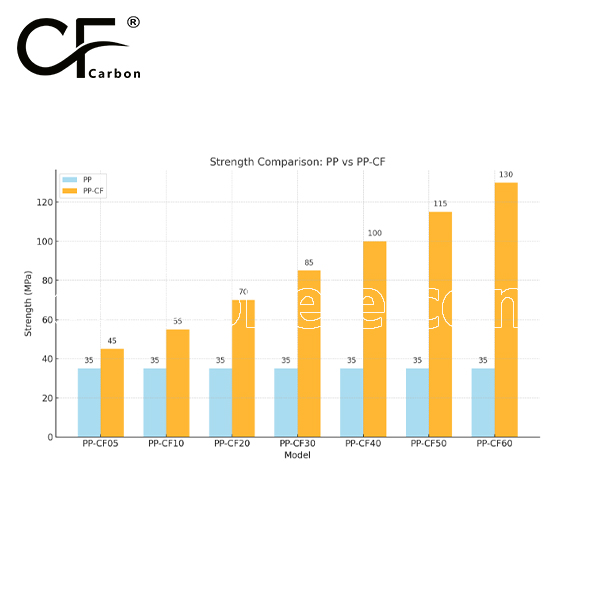

Strength between PP and PP-CF

PP-CF exhibits significantly higher strength and stiffness compared to unreinforced PP due to the addition of carbon fiber reinforcement. While standard polypropylene (PP) is known for its flexibility and impact resistance, it lacks the rigidity and load bearing capacity required for high-performance applications. In contrast, PP-CF enhances tensile strength, flexural modulus, and dimensional stability, making it more resistant to deformation under mechanical stress. This improved performance allows PP-CF to be used in applications where higher strength-to-weight ratio and structural integrity are critical.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

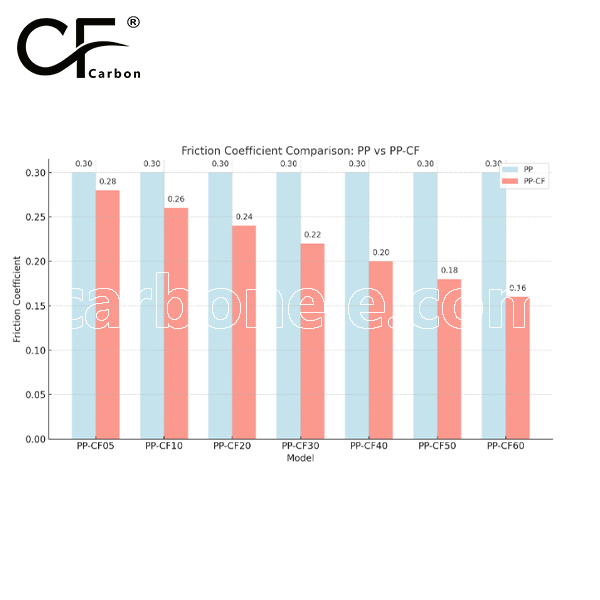

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.