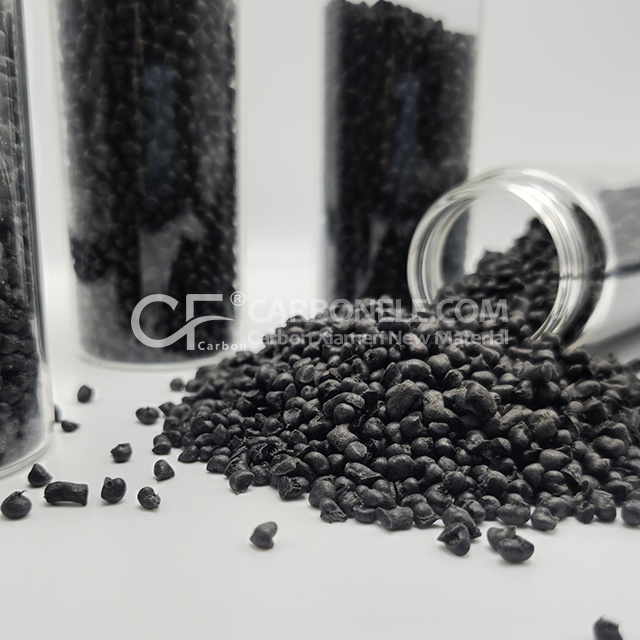

PPA-CF15 Lightweight Drone Frames for Faster Flight

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

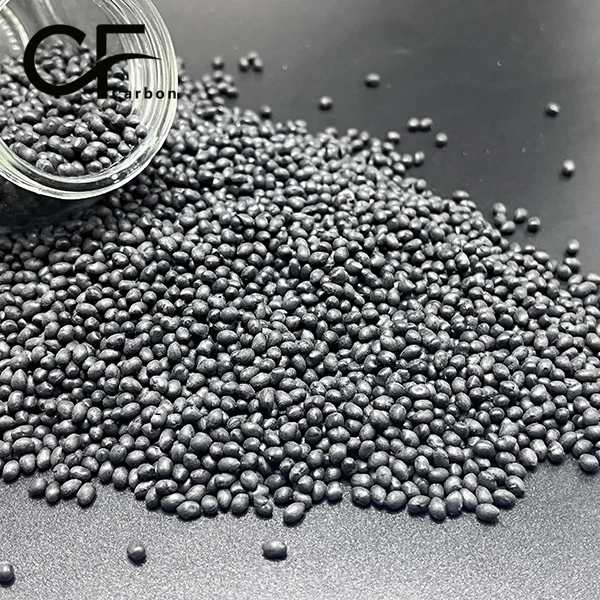

- Color: Black

- Free samples: ≤10kg

- MOQ: 100kg

- Port: Xiamen

- Model: PPA-CF-BCF3

- Matrix Resin: PPA

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PPA-CF15 Lightweight Drone Frames for Faster Flight

Drone design is evolving rapidly, and material selection directly determines flight performance and durability. PPA-CF15, a lightweight yet high-strength carbon fiber reinforced polyphthalamide composite, delivers a revolutionary performance boost for drone structures. This article uses a real-world application case to explain why PPA-CF15 is the ideal choice for drone frames.

Core Advantages of PPA-CF15

PPA-CF15 combines the toughness of engineering plastics with the strength of carbon fiber, providing excellent mechanical performance while maintaining light weight. This balance is critical in drone frames, as they need to support the power system while reducing weight for improved flight efficiency.

-

Lightweight and strong: A lighter frame means longer battery life and better maneuverability.

-

Rigid and stable: Maintains structural stability during high-speed flight or sharp turns, reducing vibration.

-

Weather resistance: PPA-CF15 retains performance in various temperature and humidity conditions, adapting to multiple flight environments.

Application Example of PPA-CF15 in Drone Frames

Taking a racing drone as an example, the frame made of PPA-CF15 allows the aircraft to respond faster and endure more in high-speed, complex racetracks.

Reduced Weight for Higher Speed

A lighter frame allows the motors to achieve a higher thrust-to-weight ratio with the same power, directly improving speed and agility. With the excellent strength-to-weight ratio of PPA-CF15, designers can reduce material usage while maintaining structural integrity.

Strong Impact Resistance

In racing, collisions are inevitable. The toughness of PPA-CF15 helps prevent frame breakage under impact, significantly reducing repair and replacement frequency.

Thermal Stability

During high-speed flights, motors and electronics generate heat. A PPA-CF15 frame maintains its shape without warping from thermal expansion or contraction, ensuring stable flight posture over time.

Potential of PPA-CF15 Beyond Drones

Although this case focuses on drone frames, the performance advantages of PPA-CF15 make it suitable for other fields that require lightweight and high strength.

Model Aircraft and Robotics

For model aircraft enthusiasts and robotics engineers, PPA-CF15 offers greater design freedom to create durable yet agile structural components.

Industrial Automation Equipment

In robotic arms or material handling devices, the high rigidity and light weight of PPA-CF15 help reduce driving energy consumption and improve operational efficiency.

Why Designers Choose PPA-CF15

Choosing PPA-CF15 is not just about lightweight performance—it’s also about reliability under extreme conditions. Drone designers use it because it:

-

Provides greater design flexibility

-

Reduces structural damage from impact

-

Adapts to multiple processing methods, lowering manufacturing difficulty

-

Balances aesthetics and function

Conclusion

The application of PPA-CF15 in lightweight drone frames demonstrates its comprehensive advantages in speed, durability, and stability. In today’s drone industry, where design is constantly pushing limits, this material brings stronger competitiveness to flying devices.

Whether for professional racing drones or consumer-grade aerial photography equipment, PPA-CF15 is an ideal choice for core structures. In the future, its potential in robotics, model aircraft, and industrial equipment will be further explored.

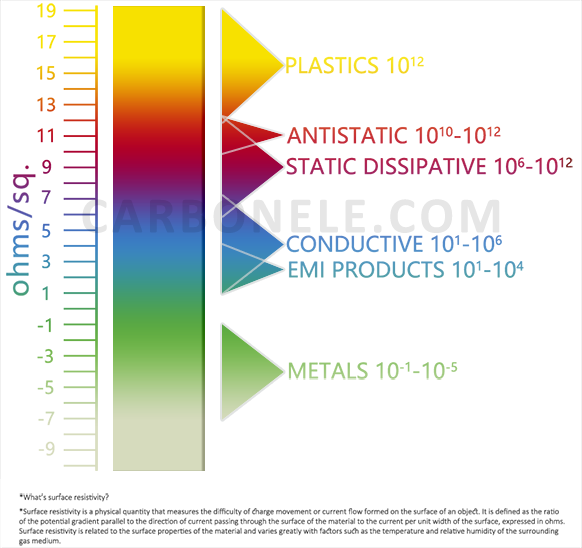

Surface Resistivity Comparison

Conductors < 10⁵ Ω/sq. Antistatic Materials 10⁵ ~ 10¹² Ω/sq. Insulators > 10¹² Ω/sq. Static-Dissipative 10⁶ ~ 10¹¹ Ω/sq. *Key Influencing Factors Humidity: Increased moisture can reduce resistivity (e.g., in polymers). Temperature: Affects carrier mobility (↑ heat may lower semiconductor resistivity). Surface Contamination: Dust/oils alter readings significantly. Additives: Carbon black, metallic fillers can lower resistivity. *Applications Electronics: Antistatic materials (10⁶–10⁹ Ω/sq) prevent electrostatic discharge (ESD). Aerospace: Composites must control resistivity to avoid charge buildup. Medical Devices: Insulating materials (>10¹² Ω/sq) ensure patient safety. *Examples Polypropylene (PP): ~10¹⁶ Ω/sq (excellent insulator). Carbon Fiber Composites: 10³–10⁶ Ω/sq (static dissipation). ESD Flooring: 10⁶–10⁹ Ω/sq.

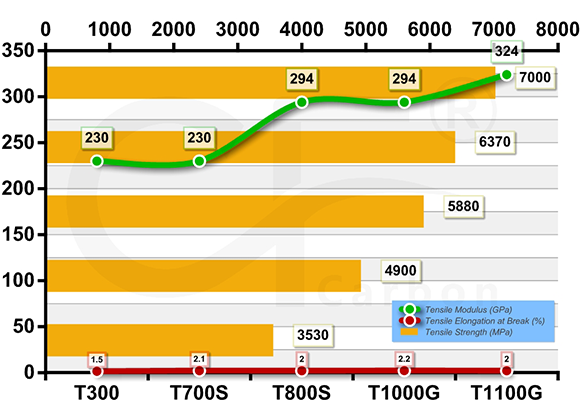

Get to Know Carbon Fibers

The table presents key performance data of carbon fiber grades. T300, with a tensile strength of 3530 MPa and a tensile modulus of 230 GPa, has a relatively low tensile elongation at break of 1.5% and a body density of 1.76 g/cm³. As the grade increases, for example, T700S shows an enhanced tensile strength of 4900 MPa compared to T300, while maintaining the same tensile modulus but with a higher elongation at break of 2.1%. T800S and T1000G both have a tensile modulus of 294 GPa, and their tensile strengths are 5880 MPa and 6370 MPa respectively. T1100G stands out with the highest tensile strength of 7000 MPa and a tensile modulus of 324 GPa. Generally, with the increase in product grade, the tensile strength and modulus tend to rise, while the density remains relatively stable around 1.8 g/cm³.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.