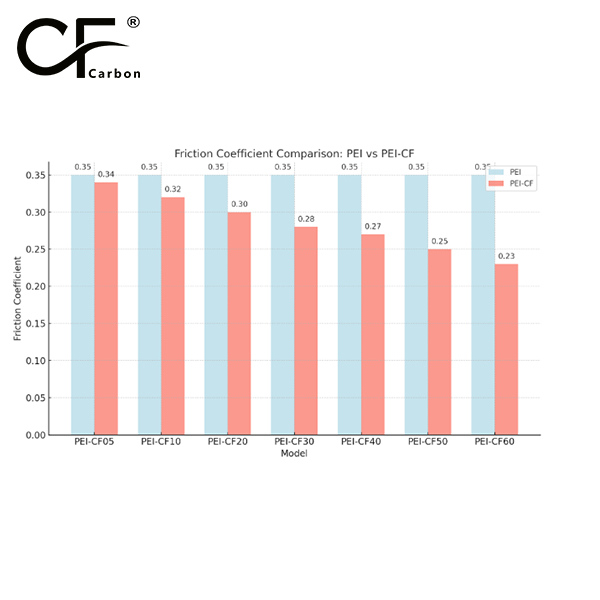

The friction coefficient of pure PEI typically ranges between 0.3 and 0.4, depending on the specific surface and conditions of use. When carbon fiber is added to create PEI-CF, the friction coefficient is generally lower due to the increased wear resistance and lubrication properties provided by the carbon fibers. For PEI-CF, the coefficient of friction typically ranges from 0.2 to 0.3, depending on the carbon fiber content and surface conditions.The addition of carbon fibers reduces friction, improves wear resistance, and enhances the material’s performance in high-stress, abrasive environments.

Precision PEI-CF30 | Electronic Connectors

PEI-CF30 carbon fiber reinforced thermoplastic offers exceptional strength and precision for electronic connectors, aerospace components, and automotive applications. Request a quote.

- Model number: PEI-CF-BCA3

- Matrix Resin: Polyethyleneimine (PEI)

- Reinforcing Filler: Carbon fiber

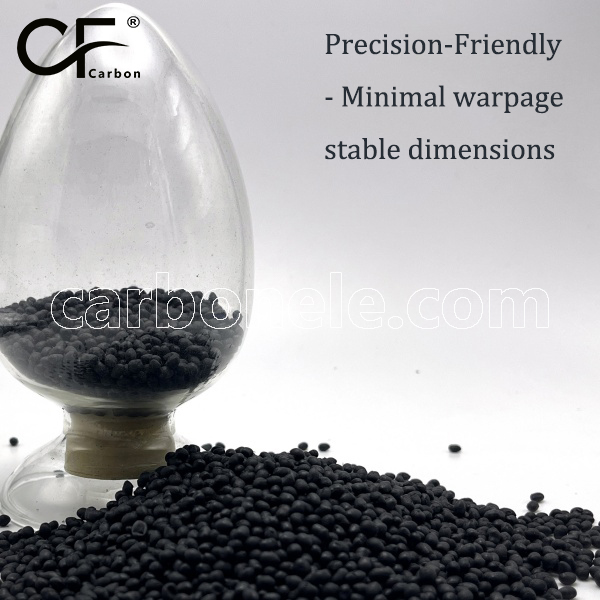

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Introduction to PEI-CF30 Material

PEI-CF30 represents a significant breakthrough in high-performance thermoplastic composites, specifically engineered to meet the demanding requirements of modern electronic applications.

This exceptional material combines the inherent advantages of polyetherimide with advanced carbon fiber reinforcement, creating a composite solution that delivers unparalleled performance in precision electronic components.

The unique properties of PEI-CF30 make it particularly valuable for electronic connector applications where reliability, precision, and durability are absolutely essential.

Electronic connectors serve as critical interfaces in countless electronic systems, requiring materials that can maintain stable electrical properties, withstand mechanical stress, and resist environmental challenges.

PEI-CF30 addresses these requirements with exceptional capability, providing electronic manufacturers with a material solution that enhances product performance while ensuring long-term reliability.

The consistent performance of PEI-CF30 makes it an ideal choice for connectors used in everything from consumer electronics to industrial control systems.

The evolution of electronic devices toward miniaturization and increased functionality has created unprecedented demands on connector materials.

PEI-CF30 meets these challenges through its exceptional combination of electrical insulation properties, mechanical strength, and dimensional stability.

This advanced material enables the production of electronic connectors that maintain their performance characteristics even under the most demanding operating conditions, making it a preferred choice for engineers and designers seeking to push the boundaries of electronic device performance.

Exceptional Properties of PEI-CF30

Superior Mechanical Performance

PEI-CF30 exhibits outstanding mechanical properties that make it exceptionally suitable for electronic connector applications.

The material maintains excellent structural integrity under various mechanical stresses, ensuring that electronic connectors can withstand repeated mating cycles without degradation of performance.

This mechanical robustness allows connectors made from PEI-CF30 to maintain precise alignment and secure connections throughout their operational lifespan.

The reinforced nature of PEI-CF30 provides exceptional resistance to deformation and warping, even when subjected to significant mechanical loads during connector insertion and extraction.

This characteristic is particularly valuable in electronic applications where maintaining precise tolerances is essential for proper electrical contact and signal integrity.

The material’s consistent mechanical performance ensures that electronic connectors maintain their exact specifications and functionality throughout extended periods of use.

Excellent Electrical Characteristics

Electrical performance represents a critical consideration in electronic connector applications, and PEI-CF30 delivers exceptional electrical properties that make it ideal for these applications.

The material provides excellent electrical insulation characteristics, preventing current leakage and ensuring signal integrity in electronic systems. This electrical stability is maintained across a wide range of environmental conditions, making PEI-CF30 reliable for various electronic applications.

The dielectric properties of PEI-CF30 remain stable under different frequency ranges and environmental conditions, ensuring consistent performance in electronic connectors used for both power transmission and signal communication.

This electrical consistency contributes to the reliability of electronic systems by minimizing signal loss and maintaining proper insulation resistance. The material’s electrical characteristics make it suitable for electronic connectors in high-frequency applications where signal integrity is paramount.

Thermal Stability and Performance

Electronic connectors often operate in environments with fluctuating temperatures, requiring materials that can maintain performance across a broad thermal range.

PEI-CF30 demonstrates exceptional thermal stability, preserving its mechanical and electrical properties even when exposed to elevated temperatures.

This thermal resistance ensures that electronic connectors perform consistently in applications where temperature variations occur.

The ability of PEI-CF30 to withstand thermal cycling without degradation makes it particularly valuable for electronic applications involving repeated temperature changes.

The material maintains its dimensional stability and mechanical properties through numerous thermal transitions, ensuring long-term reliability for electronic connectors used in environments with varying thermal conditions.

This thermal performance contributes to the overall durability and reliability of electronic systems.

PEI-CF30 in Electronic Connector Applications

Board-to-Board Connectors

PEI-CF30 finds extensive application in board-to-board connectors, where precision and stability are critical for maintaining proper alignment and electrical connection between circuit boards.

The material’s exceptional dimensional stability ensures that connectors maintain their precise spacing and alignment, preventing connection issues that could compromise electronic system performance.

Board-to-board connectors made from PEI-CF30 provide reliable interconnections in various electronic devices, from consumer electronics to industrial control systems.

The use of PEI-CF30 in board-to-board connectors contributes to improved manufacturing yields and enhanced product reliability. The material’s consistency and precision enable the production of connectors with tight tolerances, ensuring proper mating and electrical contact in electronic assemblies.

This reliability is particularly important in high-density electronic applications where space constraints demand compact connector designs without compromising performance.

Wire-to-Board Connection Systems

In wire-to-board applications, PEI-CF30 provides the structural integrity and electrical insulation required for reliable connections between wiring and circuit boards.

The material’s strength and stiffness ensure that connector housings maintain their shape and protect the delicate contacts within, while its electrical properties prevent short circuits and current leakage.

Wire-to-board connectors made from PEI-CF30 offer reliable performance in various electronic applications, including automotive electronics, industrial equipment, and consumer devices.

The durability of PEI-CF30 makes it particularly suitable for wire-to-board connectors that may be subjected to mechanical stress during installation or operation.

The material’s resistance to deformation ensures that contacts remain properly aligned and secured, maintaining electrical connectivity even in challenging environments.

This reliability contributes to the overall performance and longevity of electronic systems using these connection systems.

RF and High-Frequency Connectors

PEI-CF30’s stable dielectric properties make it an excellent choice for RF and high-frequency connectors used in communication systems and high-speed electronic devices.

The material’s consistent electrical characteristics ensure minimal signal loss and maintained impedance matching, which are critical factors in high-frequency applications. RF connectors made from PEI-CF30 provide reliable performance in wireless communication devices, network equipment, and other high-frequency electronic systems.

The precision achievable with PEI-CF30 allows for the manufacturing of RF connectors with exact dimensional tolerances, ensuring proper impedance characteristics and signal integrity.

The material’s stability under various environmental conditions contributes to consistent performance in high-frequency applications where even minor variations can significantly impact signal quality.

This reliability makes PEI-CF30 valuable for critical communication infrastructure and high-performance electronic devices.

Manufacturing Advantages of PEI-CF30

Precision Moldability

PEI-CF30 offers exceptional moldability characteristics that enable the production of electronic connectors with complex geometries and tight tolerances.

The material flows smoothly in molding processes, allowing for the creation of intricate features necessary for modern connector designs.

This precision moldability ensures that electronic connectors maintain their designed specifications and functional requirements throughout production.

The consistency of PEI-CF30 during molding processes contributes to high manufacturing yields and reduced production costs.

The material’s stability allows for predictable processing parameters, minimizing variations between production batches and ensuring consistent quality in electronic connector manufacturing.

This manufacturing reliability is essential for meeting the stringent quality requirements of the electronics industry.

Surface Finish Quality

Electronic connectors often require excellent surface finishes for both functional and aesthetic reasons, and PEI-CF30 delivers superior surface quality in molded components.

The material’s molding characteristics allow for the production of smooth surfaces that facilitate easy connector mating and prevent particle generation.

This surface quality is particularly important in electronic applications where contamination could affect performance.

The ability of PEI-CF30 to maintain dimensional stability during and after molding ensures that surface features remain precise and consistent.

This consistency contributes to the reliable performance of electronic connectors by ensuring proper contact alignment and maintaining the integrity of sealing surfaces where required.

The material’s surface properties also allow for effective plating or coating when additional functionality or protection is needed.

Quality and Reliability Assurance

Consistent Material Performance

PEI-CF30 undergoes rigorous quality control measures to ensure consistent performance in electronic connector applications.

The material’s properties are carefully monitored throughout the manufacturing process, guaranteeing that each batch meets the strict requirements necessary for electronic components.

This consistency ensures that electronic connectors perform reliably across different production lots and applications.

The reliable performance of PEI-CF30 contributes to the overall quality of electronic systems by providing consistent material properties that designers can depend on.

This consistency allows for accurate prediction of performance characteristics and ensures that electronic connectors meet their specified requirements throughout their operational lifespan.

The material’s stability supports the production of high-reliability electronic devices that meet customer expectations for performance and durability.

Long-Term Reliability

Electronic connectors made from PEI-CF30 demonstrate exceptional long-term reliability, maintaining their performance characteristics through extended periods of use and numerous mating cycles.

The material’s resistance to environmental factors, including temperature fluctuations and chemical exposure, ensures that connectors continue to perform reliably in various operating conditions. This longevity contributes to the overall durability of electronic systems.

The stability of PEI-CF30 under electrical stress ensures that connectors maintain their insulation properties and dimensional integrity over time.

This long-term reliability is particularly important in electronic applications where connector failure could result in system downtime or compromised performance.

The material’s durability supports the development of electronic products with extended service lives and reduced maintenance requirements.

Conclusion: Advancing Electronic Connectivity with PEI-CF30

PEI-CF30 represents a significant advancement in materials technology for electronic connector applications, offering a unique combination of properties that address the evolving needs of the electronics industry. Its exceptional mechanical strength, electrical performance, and thermal stability make it an ideal choice for various connector types, from board-to-board interconnections to high-frequency RF applications.

The material’s consistency and reliability support the production of electronic devices that meet increasingly demanding performance requirements.

As electronic devices continue to evolve toward higher speeds, greater functionality, and increased miniaturization, materials like PEI-CF30 will play an increasingly important role in enabling these advancements.

The continued development and optimization of PEI-CF30 for electronic applications will contribute to further improvements in connector performance, reliability, and manufacturing efficiency.

This progress supports the electronics industry’s ongoing innovation and the development of new technologies that depend on reliable electronic connectivity.

The adoption of PEI-CF30 in electronic connector applications represents a commitment to quality, reliability, and performance excellence. By choosing this advanced material, manufacturers can create electronic products that deliver superior performance while meeting the demanding requirements of modern electronic applications.

This commitment to excellence through material selection contributes to the advancement of electronic technology and the development of innovative products that enhance how people live and work.

If you want to get more information about PEI-CF60, you can visit our YouTube.

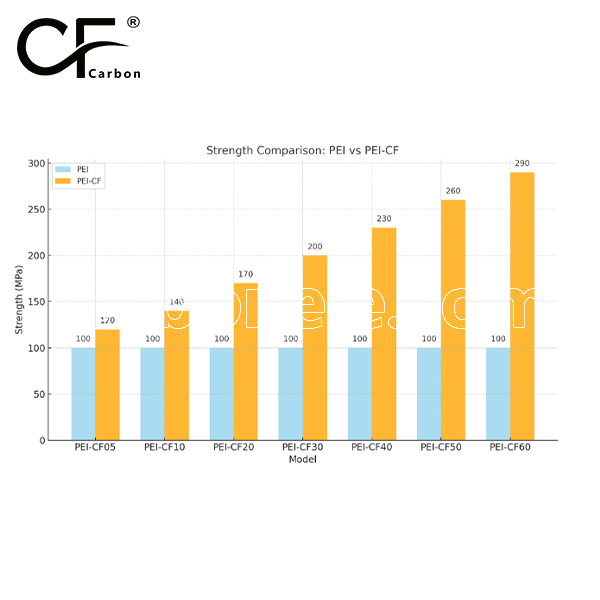

Strength between PEI and PEI-CF

PEI offers strong mechanical properties, excellent thermal stability, and chemical resistance for moderate duty applications. PEI-CF, with added carbon fiber, significantly enhances stiffness, wear resistance, and mechanical strength, making it ideal for high performance environments that require superior strength and durability under stress.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.