Stable PP-LCF20 for Robotic Joint Arms

- Model number: PP-LCF-BAC2

- Matrix Resin: Polypropylene

- Reinforcing Filler: Carbon fiber(20%)

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Stable PP-LCF20 for Robotic Joint Arms

Introduction to PP-LCF20

PP-LCF20 is a specialized thermoplastic composite designed for industries where balance between lightweight structure and enhanced stability is required.

This material is an advanced modification of polypropylene, combined with long carbon fiber reinforcement, to deliver a stable solution for components that need both mechanical performance and durability.

One of the most notable application examples is in robotic joint arms, where precision, balance, and long-lasting reliability are critical.

When designers and engineers select a material for robotic systems, they often face the challenge of balancing performance and cost efficiency.

It offers the right combination by delivering stiffness, impact resistance, and weight reduction while remaining a cost-effective alternative to other engineering composites.

Why Robotic Joint Arms Require PP-LCF20

Precision and Stability in Robotic Motion

Robotic joint arms require stability and repeatable performance in every movement. A material like PP-LCF20 ensures that structural deflection is minimized, keeping the robotic motion consistent and precise.

Its reinforced matrix resists micro-deformation under repetitive load cycles, ensuring long-term durability without compromising flexibility in design.

Lightweight for Energy Efficiency

Reducing weight in robotic arms directly improves energy efficiency, as motors consume less power to move lighter components.

It, with its carbon fiber reinforcement, offers substantial weight savings compared to traditional engineering plastics or metal solutions. This means longer operation cycles and reduced wear on motor systems.

Enhanced Durability Against Wear

Robotic arms often perform continuous, repetitive tasks in industrial environments. Materials without reinforcement may degrade faster, leading to maintenance downtime.

It brings superior wear resistance and dimensional stability, extending the service life of robotic parts and reducing maintenance costs.

Key Benefits of PP-LCF20

Mechanical Strength with Lightweight Profile

The integration of long carbon fibers in PP-LCF20 drastically improves stiffness without adding unnecessary weight.

This ensures that the final component can withstand operational stresses while remaining easy to move.

Excellent Dimensional Stability

For robotic arms, dimensional accuracy is essential. It maintains its structure even in environments with fluctuating temperatures or constant mechanical stress.

Superior Impact Resistance

Unlike brittle materials that can fracture under shock or sudden loads, it absorbs and redistributes impact energy effectively.

This property protects robotic systems from damage during unexpected collisions or heavy cycles.

Cost-Effective Engineering Solution

Compared to high-end composites or specialty resins, it provides a competitive advantage in cost-performance balance.

It delivers the required technical performance while remaining an economical option for large-scale production.

Application Example: Robotic Joint Arms

Smooth and Controlled Movements

In robotic joint arms, smooth operation depends on both the precision of the motor system and the integrity of the material.

It ensures that joints stay stable, helping robots perform repetitive tasks like assembly, inspection, or packaging without deviation.

Long-Term Reliability

Maintenance costs in industrial robotics can be significant. By using PP-LCF20, manufacturers reduce the risk of wear-related failures, thereby ensuring continuous uptime in factories or automated facilities.

Lightweight Structural Integration

Traditional metals often increase the overall mass of robotic systems. Switching to PP-LCF20 offers significant weight savings, which in turn reduces energy consumption and improves speed and responsiveness in motion.

Design Opportunities with PP-LCF20

Complex Geometries Made Simple

It can be processed into complex shapes without sacrificing structural performance. This allows engineers to design intricate robotic components that are both strong and lightweight.

Surface Finishing and Aesthetic Options

Beyond functionality, It also supports excellent surface finishing. Robotic arms can be designed not only for performance but also for clean and professional appearance, suitable for modern industrial environments.

Compatibility with Modern Manufacturing

It is well-suited for injection molding, extrusion, and other advanced processing methods. This makes it compatible with high-volume production while maintaining consistency in part quality.

Comparing PP-LCF20 with Other Materials

Metals vs PP-LCF20

While metals provide strength, they add unnecessary weight and may corrode in certain conditions. It offers strength with reduced mass and inherent corrosion resistance.

Traditional Plastics vs PP-LCF20

Unreinforced plastics are lighter but lack stiffness and wear resistance. It bridges the gap by combining lightweight properties with mechanical durability.

High-End Composites vs PP-LCF20

High-end composites may outperform PP-LCF20 in extreme conditions, but they are often cost-prohibitive. It stands out as a balanced choice for industrial applications where reliability and economy must coexist.

Industry Applications Beyond Robotics

While robotic joint arms are a leading application, it extends its usability into multiple sectors:

Automotive: For lightweight brackets, housings, and under-the-hood parts.

Consumer Electronics: Structural casings that demand both strength and slim designs.

Appliances: Internal moving parts where wear resistance and stability are required.

Industrial Machinery: Load-bearing components exposed to repetitive use.

Sustainability Aspect of PP-LCF20

It contributes to sustainability goals in manufacturing. Its lightweight profile reduces energy usage during operation, and its long service life minimizes waste caused by frequent part replacement.

Furthermore, the processing of PP-LCF20 consumes less energy compared to certain specialty composites, making it an environmentally responsible choice.

Future Potential of PP-LCF20

The growing demand for automation ensures that materials like PP-LCF20 will play an even larger role in the future.

As industries seek materials that combine performance, design flexibility, and sustainability, it positions itself as a reliable solution. Its adaptability makes it relevant for evolving trends such as collaborative robots, smart machinery, and energy-efficient devices.

Conclusion

It stands as a versatile material tailored for modern engineering needs. In robotic joint arms, it ensures stability, durability, and efficiency, helping systems achieve precision without sacrificing energy performance.

Its balance of lightweight strength, cost-effectiveness, and design flexibility makes it a strategic material not just for robotics, but for a wide spectrum of industries.

For manufacturers seeking stability in design, reliability in operation, and long-term value, it offers the exact upgrade needed for next-generation applications.

.If you want to get more information , you can visit our Youtube.

Click here to contact us

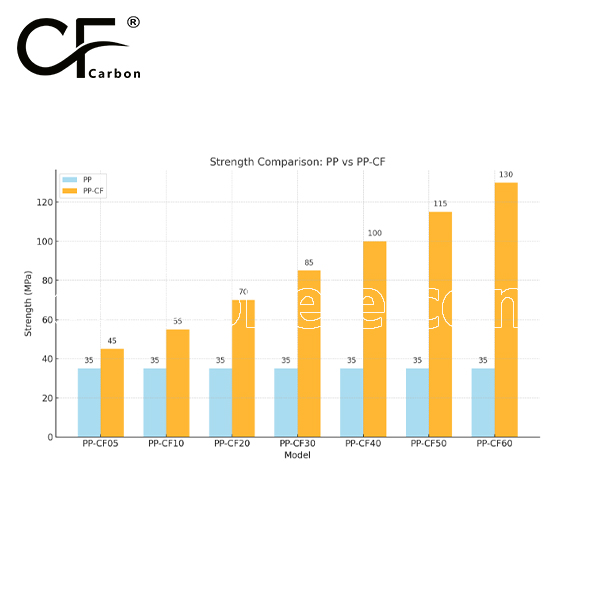

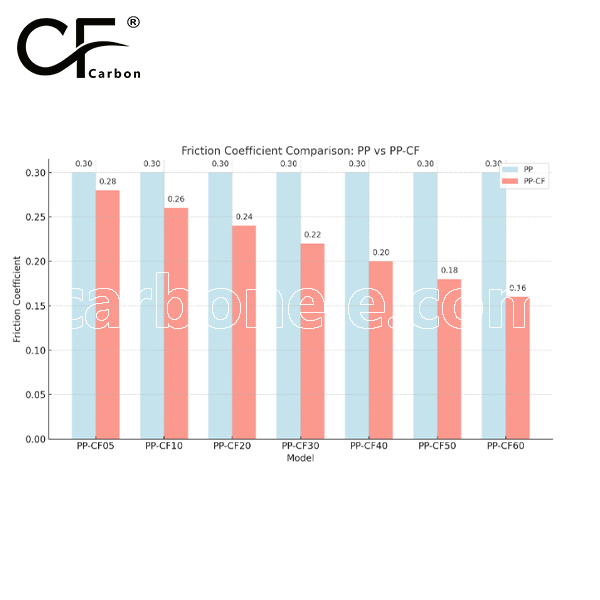

Strength between PP and PP-CF

PP-CF exhibits significantly higher strength and stiffness compared to unreinforced PP due to the addition of carbon fiber reinforcement. While standard polypropylene (PP) is known for its flexibility and impact resistance, it lacks the rigidity and load bearing capacity required for high-performance applications. In contrast, PP-CF enhances tensile strength, flexural modulus, and dimensional stability, making it more resistant to deformation under mechanical stress. This improved performance allows PP-CF to be used in applications where higher strength-to-weight ratio and structural integrity are critical.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.