Stable PA612 CF30 Composite – Ideal for Electronics

PA612 CF30 carbon fiber composite—high-strength, lightweight material for electronics & industrial parts. Superior dimensional stability & heat resistance. Request specs!

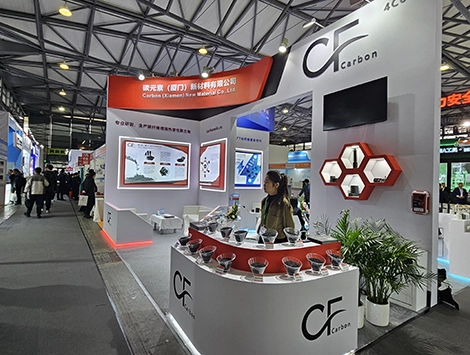

- Manufacturer: Carbon New Material

- OEM/ODM: Acceptable

- Color: Black

- Free samples: ≤10kg

- MOQ: 100kg

- Port: Xiamen

- Model number: PA612-CF-BCA3

- Matrix Resin: PPA

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Stable PA612 CF30 Composite—Ideal for Electronics

Introduction to PA612 CF30

PA612 CF30 is a modern composite material that blends the resilience of polyamide with the reinforcement of carbon fibers. It stands as a premium solution in the engineering plastics industry, where precision, durability, and long-term reliability are essential.

This material has become increasingly valuable in sectors that require both structural stability and excellent performance under demanding conditions.

The name PA612 CF30 refers to a composite in which polyamide 612 is combined with carbon fiber reinforcement. The result is a stable, lightweight, and mechanically strong material that offers a balance between toughness, dimensional stability, and long-term resistance to environmental influences.

Within electronic applications, where durability, compactness, and design integrity are crucial, PA612 CF30 delivers consistent results. Its engineered composition makes it an excellent choice for manufacturers seeking to replace heavier metals or less stable plastics without compromising on performance.

Why Choose PA612 CF30 for Electronics

When designing electronic devices, engineers must carefully balance multiple factors, including mechanical stability, resistance to heat, and electrical insulation. PA612 CF30 answers these challenges effectively by providing:

Strength with lightness: It allows components to remain structurally sound without adding unnecessary bulk.

Heat resistance: Electronic components often generate heat, and this composite ensures that parts retain their integrity even under elevated temperatures.

Dimensional accuracy: Stability under moisture and varying conditions helps electronic devices maintain precise fits.

Aesthetic surface quality: Components molded from PA612 CF30 exhibit refined finishes suitable for both visible and hidden parts of electronics.

Because of these features, it is particularly valued for casings, structural brackets, and functional housings within consumer and industrial electronics.

Application Example: Electronic Device Housing

To illustrate the value of PA612 CF30, consider its application in electronic device housing. In modern electronics, housings must provide both protection and support for sensitive internal systems. PA612 CF30 fulfills this dual role effectively:

Protective Shield: The carbon fiber reinforcement ensures that the housing can withstand shocks, pressure, and long-term usage.

Heat Dissipation Balance: The composite does not deform easily under the thermal influence of circuit boards or chips.

Precision Fit: Even thin-walled housings maintain rigidity and dimensional stability, ensuring reliable assembly.

This makes PA612 CF30 ideal for laptops, tablets, communication devices, and industrial control systems.

Advantages of PA612 CF30 in Electronics

Mechanical Strength and Reliability

The integration of carbon fiber in PA612 CF30 dramatically improves its load-bearing capabilities. This means electronic devices that experience pressure, bending, or handling stress remain dependable over time.

Lightweight Performance

As electronics become more compact and portable, weight reduction is essential. PA612 CF30 offers the same structural resilience as many heavier materials, yet keeps devices lighter and easier to carry.

Dimensional Stability Under Stress

Moisture, heat, and external mechanical forces often cause plastics to warp or lose accuracy. With PA612 CF30, the dimensional stability is preserved, supporting reliable long-term operation in electronic assemblies.

Aesthetic and Surface Finishing

For consumer electronics, the look and feel of the product housing matters. PA612 CF30 not only delivers technical excellence but also allows smooth and uniform surface finishes suitable for direct use or post-processing.

Expanding Beyond Electronics: Broader Applications of PA612 CF30

While electronics are a key sector, PA612 CF30 has also proven valuable in:

Automotive: Structural brackets, under-the-hood components, and interior support parts.

Industrial Machinery: Gears, housings, and parts exposed to repetitive stress.

Consumer Goods: High-performance sporting equipment and premium lifestyle products.

Energy Systems: Lightweight housings for power equipment and renewable energy technology.

In each application, the balance between stability, lightweight structure, and mechanical resilience positions PA612 CF30 as a highly versatile material.

Design Freedom with PA612 CF30

Versatility in Molding

PA612 CF30 is compatible with advanced molding processes, enabling manufacturers to create highly detailed and complex designs without sacrificing integrity. This allows for thin walls, intricate shapes, and integrated fastening features.

Consistent Quality

Manufacturers benefit from a material that flows evenly during molding, ensuring reduced defects and consistent results across production runs.

Long-Term Reliability

Devices and systems created with PA612 CF30 demonstrate dependable long-term use, minimizing warranty issues and enhancing customer trust.

Sustainability and PA612 CF30

Modern industries value not only performance but also sustainability. PA612 CF30 contributes by:

Reducing material waste through high efficiency in molding processes.

Replacing metals with a lighter composite, reducing transportation energy.

Supporting recyclability in the broader thermoplastic composites field.

By adopting PA612 CF30, businesses align their products with eco-conscious manufacturing while maintaining competitive technical standards.

Customer Benefits of Choosing PA612 CF30

Reliability: Devices last longer with fewer material-related failures.

Lightweight Efficiency: Reduced shipping costs and easier portability.

Performance Assurance: Confidence in high-precision, dimensionally stable components.

Market Appeal: Products gain a premium reputation by integrating high-quality composites.

Future Outlook of PA612 CF30

The demand for PA612 CF30 is expected to expand as electronics and industrial products push for stronger, lighter, and more sustainable materials. As industries evolve, this composite will continue to be a cornerstone in innovation, bridging the gap between conventional plastics and heavier engineering materials.

Conclusion

PA612 CF30 represents the intersection of performance, stability, and forward-thinking material science. From protecting delicate electronic systems to enabling lightweight yet strong structures across industries, its role is indispensable.

For manufacturers seeking to enhance the performance of their electronics, PA612 CF30 is not just a material—it is a foundation for innovation, design freedom, and long-term success.

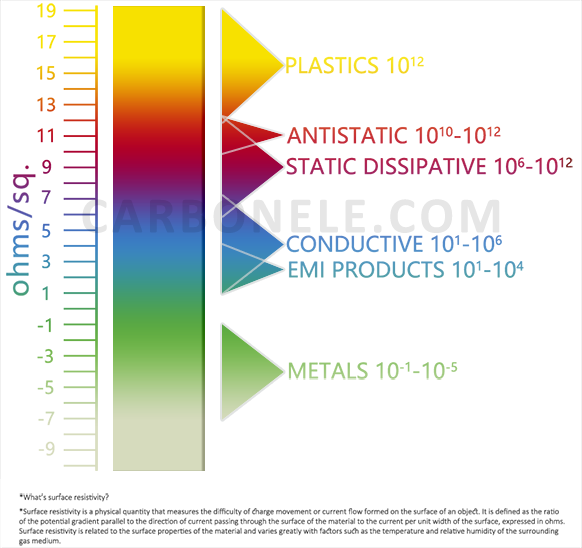

Surface Resistivity Comparison

Conductors < 10⁵ Ω/sq. Antistatic Materials 10⁵ ~ 10¹² Ω/sq. Insulators > 10¹² Ω/sq. Static-Dissipative 10⁶ ~ 10¹¹ Ω/sq. *Key Influencing Factors Humidity: Increased moisture can reduce resistivity (e.g., in polymers). Temperature: Affects carrier mobility (↑ heat may lower semiconductor resistivity). Surface Contamination: Dust/oils alter readings significantly. Additives: Carbon black, metallic fillers can lower resistivity. *Applications Electronics: Antistatic materials (10⁶–10⁹ Ω/sq) prevent electrostatic discharge (ESD). Aerospace: Composites must control resistivity to avoid charge buildup. Medical Devices: Insulating materials (>10¹² Ω/sq) ensure patient safety. *Examples Polypropylene (PP): ~10¹⁶ Ω/sq (excellent insulator). Carbon Fiber Composites: 10³–10⁶ Ω/sq (static dissipation). ESD Flooring: 10⁶–10⁹ Ω/sq.

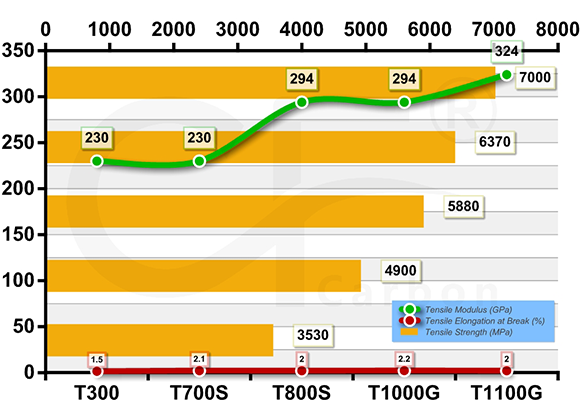

Get to Know Carbon Fibers

The table presents key performance data of carbon fiber grades. T300, with a tensile strength of 3530 MPa and a tensile modulus of 230 GPa, has a relatively low tensile elongation at break of 1.5% and a body density of 1.76 g/cm³. As the grade increases, for example, T700S shows an enhanced tensile strength of 4900 MPa compared to T300, while maintaining the same tensile modulus but with a higher elongation at break of 2.1%. T800S and T1000G both have a tensile modulus of 294 GPa, and their tensile strengths are 5880 MPa and 6370 MPa respectively. T1100G stands out with the highest tensile strength of 7000 MPa and a tensile modulus of 324 GPa. Generally, with the increase in product grade, the tensile strength and modulus tend to rise, while the density remains relatively stable around 1.8 g/cm³.

How to Buy?

If you want to obtain information such as product specifications, performance, and price, choose a suitable product according to your own needs. Meanwhile, you can ask the manufacturer to provide samples for testing to ensure that the material meets your usage requirements. If you are interested in purchasing this composite material, please contact the manufacturer Carbon (Xiamen) New Material directly.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.