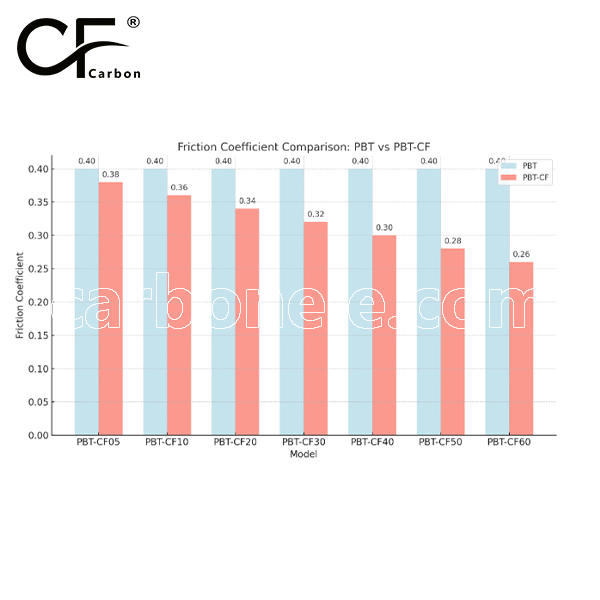

The friction coefficient of PEI-LCF (PEI reinforced with carbon fibers) is generally lower than that of pure PEI due to the enhanced wear resistance and smoothness provided by the carbon fiber reinforcement. While pure PEI typically has a friction coefficient between 0.2 and 0.4, PEI-LCF, depending on the carbon fiber content, can have a reduced friction coefficient ranging from 0.1 to 0.3. The higher the carbon fiber content, the lower the friction coefficient, making PEI-LCF more suitable for high-performance applications that require reduced friction and improved wear resistance.

Stable PBT-CF10 Specialty Plastic for Auto Mirror Mounts

Discover PBT-CF10 specialty plastic for auto mirror mounts. This carbon fiber-reinforced material offers superior stability, vibration damping, and environmental resistance for automotive applications

- Model number: PBT-CF-BCA1

- Matrix Resin: polybutylene terephthalate (PBT)

- Reinforcing Filler: Carbon fiber

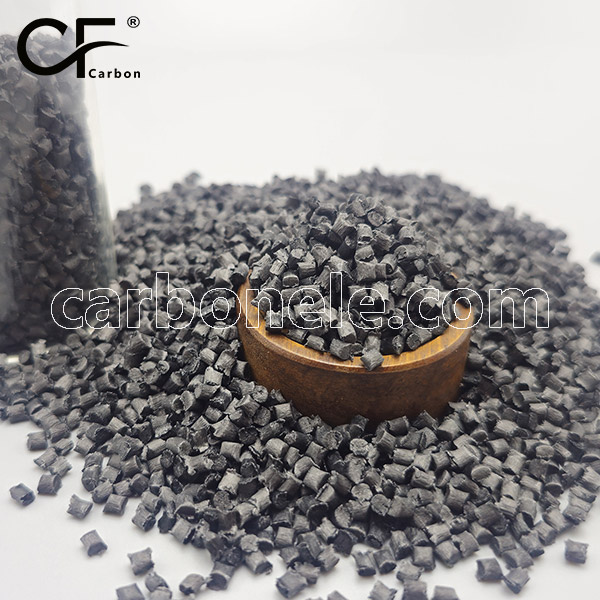

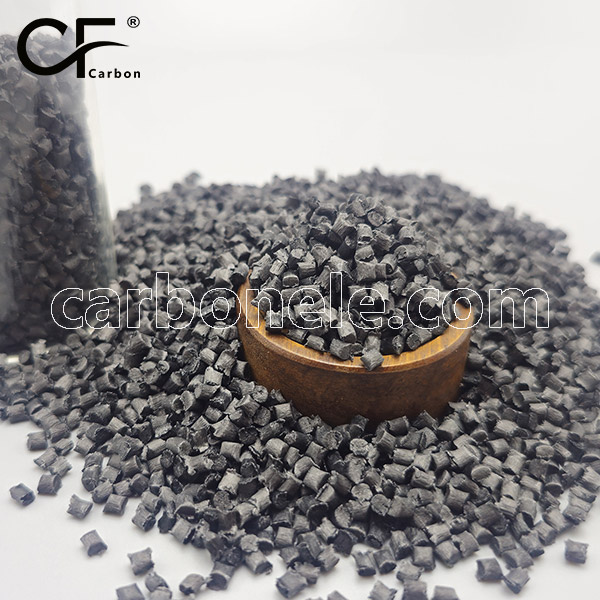

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

PBT-CF10: The Stable Specialty Plastic for High-Performance Auto Mirror Mounts

In the automotive industry, every component must meet rigorous standards of durability, reliability, and performance. Auto mirror mounts, though often overlooked, play a critical role in vehicle safety and functionality.

These components must withstand constant vibration, temperature fluctuations, and mechanical stress while maintaining precise positioning. For manufacturers seeking a material that delivers exceptional stability and strength, it emerges as the premier choice.

This advanced carbon fiber-reinforced thermoplastic combines the inherent benefits of polybutylene terephthalate with the enhanced mechanical properties of carbon fiber, creating a material specifically engineered for demanding automotive applications.

PBT-CF10 offers a unique blend of dimensional stability, resistance to environmental factors, and lightweight durability, making it an ideal solution for auto mirror mounts and other critical automotive components.

Understanding PBT-CF10: A Material Engineered for Excellence

PBT-CF10 represents a significant advancement in thermoplastic technology. By integrating carbon fiber reinforcement into a PBT matrix, this material achieves a level of performance that surpasses conventional plastics and even some metals.

The result is a specialty plastic that excels in applications where stability, strength, and resistance to harsh conditions are paramount. It is not just another composite; it is a carefully formulated material designed to meet the exacting requirements of the automotive industry.

Its unique properties make it particularly well-suited for components like auto mirror mounts, where failure is not an option.

Key Properties of PBT-CF10 for Automotive Applications

The exceptional performance of PBT-CF10 in auto mirror mounts and similar components stems from its combination of critical properties. These properties work in harmony to ensure that parts manufactured from PBT-CF10 meet the highest standards of quality and reliability.

Superior Dimensional Stability

One of the most important attributes of PBT-CF10 is its outstanding dimensional stability. Auto mirror mounts must maintain their precise shape and alignment despite exposure to temperature variations, humidity, and constant vibration.

It exhibits minimal expansion or contraction under changing environmental conditions, ensuring that mirror mounts retain their exact specifications over time.

This stability is crucial for maintaining the proper alignment of mirrors, which directly impacts driver visibility and vehicle safety.

Enhanced Mechanical Strength

The incorporation of carbon fiber reinforcement significantly enhances the mechanical strength of PBT-CF10. Auto mirror mounts manufactured from this material demonstrate remarkable resistance to bending, torsion, and impact forces.

This strength ensures that mirrors remain securely positioned even when subjected to accidental impacts or rough road conditions. The robustness of PBT-CF10 provides automotive manufacturers with confidence in the longevity and reliability of their mirror mount systems.

Excellent Vibration Damping

Automotive environments are characterized by constant vibration from engines, road surfaces, and vehicle movement. It possesses inherent vibration damping properties that make it exceptionally suitable for auto mirror mounts.

The material absorbs and dissip vibrational energy, preventing the transmission of oscillations to the mirror assembly. This results in clearer, more stable mirror images for the driver, enhancing overall safety and comfort during operation.

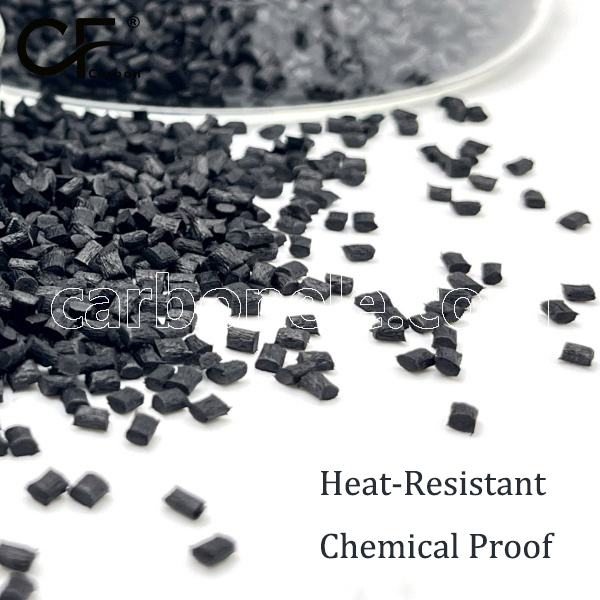

Resistance to Environmental Factors

Auto mirror mounts are exposed to various environmental challenges, including temperature extremes, UV radiation, moisture, and exposure to automotive fluids.

It demonstrates excellent resistance to these factors, maintaining its properties and appearance under demanding conditions. The material’s resistance to UV degradation prevents yellowing or embrittlement, while its low moisture absorption ensures consistent performance in humid or wet environments.

Application Focus: PBT-CF10 in Auto Mirror Mounts

The use of PBT-CF10 in auto mirror mounts represents a perfect marriage of material properties and application requirements.

Mirror mounts must perform flawlessly in all driving conditions while contributing to vehicle safety and aesthetics. It addresses all these needs with its unique combination of characteristics.

The Critical Role of Auto Mirror Mounts

Auto mirror mounts serve as the structural interface between the vehicle body and the mirror assembly. They must support the weight of the mirror while maintaining precise positioning adjustments.

Additionally, mirror mounts must absorb road vibrations, withstand temperature variations from extreme cold to intense heat, and resist degradation from UV exposure and automotive chemicals.

Failure of a mirror mount can compromise driver visibility, potentially leading to dangerous situations. This is why material selection for auto mirror mounts is so crucial to vehicle safety and performance.

How PBT-CF10 Enhances Mirror Mount Performance

Auto mirror mounts manufactured from PBT-CF10 benefit from the material’s comprehensive property profile. The dimensional stability of PBT-CF10 ensures that mounts maintain their precise tolerances through seasonal temperature changes.

The mechanical strength of PBT-CF10 provides the necessary support for mirror assemblies, including those with integrated electronic components for positioning and heating.

The vibration damping characteristics of PBT-CF10 contribute to clearer mirror images by reducing shake and blur. Furthermore, the environmental resistance of PBT-CF10 ensures that mirror mounts continue to perform reliably throughout the vehicle’s lifespan, regardless of climate or operating conditions.

Manufacturing Advantages with PBT-CF10

Beyond its performance benefits, PBT-CF10 offers significant advantages in the manufacturing process of auto mirror mounts. The material exhibits excellent flow characteristics during injection molding, allowing for the production of complex geometries with tight tolerances.

This capability enables designers to create optimized mount designs that integrate multiple functions, such as attachment points, cable routing channels, and reinforcement features. The processability of PBT-CF10 also contributes to reduced cycle times and improved manufacturing efficiency, making it an economically viable choice for high-volume automotive production.

Beyond Mirror Mounts: Other Automotive Applications for PBT-CF10

While auto mirror mounts represent an ideal application for PBT-CF10, the material’s properties make it suitable for numerous other automotive components.

The same characteristics that benefit mirror mounts—dimensional stability, mechanical strength, vibration damping, and environmental resistance—also make PBT-CF10 valuable for other under-hood and exterior applications.

Engine Components

PBT-CF10’s temperature resistance and structural integrity make it suitable for various engine compartment components.

These may include sensor housings, connector bodies, and support brackets that must withstand elevated temperatures while maintaining precise dimensions and electrical insulation properties.

Electrical Systems

The material’s combination of mechanical properties and electrical characteristics makes PBT-CF10 appropriate for automotive electrical applications. These can include housing for electronic control units, connector systems, and various electrical components that require stability, strength, and reliability.

Exterior Trim Components

PBT-CF10’s resistance to environmental factors and its ability to maintain appearance make it suitable for exterior trim components. These may include badge emblems, grille elements, and other exterior parts that require durability, weatherability, and consistent appearance over time.

The Manufacturing Advantage of PBT-CF10

The production benefits of PBT-CF10 extend beyond its material properties to encompass manufacturing efficiency and design flexibility. These advantages make PBT-CF10 not just a high-performance material but also a practical choice for automotive manufacturers.

Design Flexibility

PBT-CF10 enables designers to create complex, integrated components that might require multiple parts if made from traditional materials.

The material’s strength and stability allow for thinner wall sections and more ambitious designs while maintaining structural integrity. This flexibility can lead to component consolidation, reduced assembly requirements, and ultimately, lighter and more cost-effective solutions.

Production Efficiency

The processing characteristics of PBT-CF10 contribute to manufacturing efficiency through reduced cycle times, lower rejection rates, and improved mold replication.

These factors combine to make PBT-CF10 an economically attractive option for automotive components, particularly those produced in high volumes like auto mirror mounts.

Quality Consistency

Batch-to-batch consistency is crucial in automotive manufacturing. It delivers reliable, predictable performance in production environments, ensuring that every auto mirror mount or other component meets the same high standards.

This consistency reduces quality control issues and contributes to overall manufacturing reliability.

Why Choose PBT-CF10 for Your Automotive Components

Selecting PBT-CF10 for auto mirror mounts and other automotive applications represents a commitment to quality, safety, and performance. The material’s unique combination of properties addresses the specific challenges faced by automotive components while offering manufacturing and design benefits.

For automotive manufacturers seeking to enhance their products’ reliability and performance, it provides a material solution that meets today’s demands while anticipating tomorrow’s challenges.

Experience the PBT-CF10 Advantage

Discover how PBT-CF10 can transform your automotive component designs, starting with auto mirror mounts. Our specialty plastic offers the perfect balance of stability, strength, and manufacturing versatility that modern automotive applications require.

Contact us today to learn more about PBT-CF10, request material samples, and discuss how this advanced material can enhance your automotive components. With PBT-CF10, you’re not just choosing a material—you’re choosing a partnership dedicated to your manufacturing success and product excellence.

If you want to get more information about PBT-CF60, you can visit our Youtube.

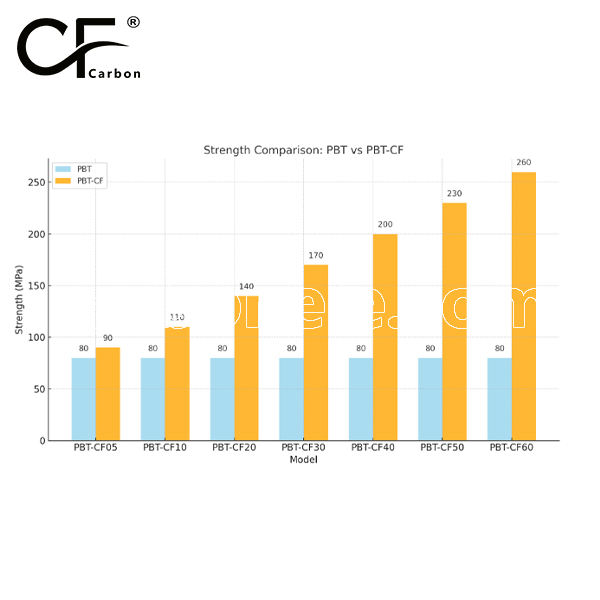

Strength between PBT and PBT-CF

PBT (Polybutylene Terephthalate) is known for its excellent mechanical properties, including good stiffness and strength, but when reinforced with carbon fiber, such as in PBT-CF, these properties are significantly enhanced. The addition of carbon fiber in PBT-CF improves its tensile strength, flexural strength, and impact resistance, making it more durable and resistant to deformation under high mechanical loads. While PBT performs well under moderate stress, PBT-CF is designed for applications requiring higher stiffness, greater structural integrity, and better wear resistance, making it ideal for more demanding environments where enhanced performance is required.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

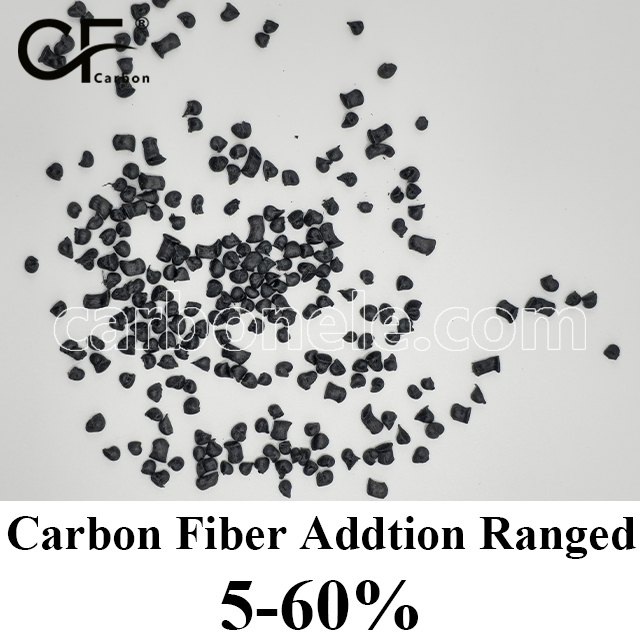

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.