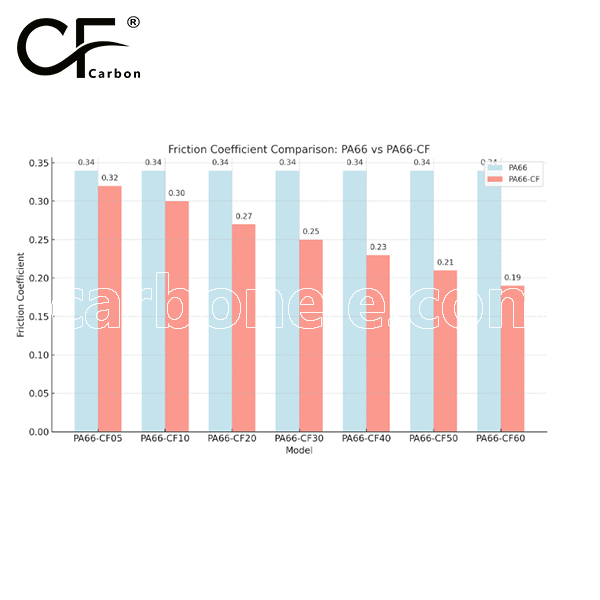

The friction coefficient of PA66-CF is significantly lower than that of unreinforced PA66, thanks to the presence of carbon fiber, which acts as a solid lubricant. While PA66 already offers decent wear resistance, the addition of carbon fiber greatly enhances its tribological performance by reducing surface friction and improving wear resistance under load and repeated motion. This makes PA66-CF especially suitable for applications involving sliding contact or dynamic mechanical stress.

Superior Heat-Resistant PA66-LCF20 | Ideal for Auto Engine Covers

Superior PA66-LCF20 long carbon fiber nylon composite. Ideal heat-resistant material for durable auto engine covers. Withstands vibration, chemicals & high temperatures. Engineered for automotive excellence.

- Model number: PA66-LCF-BCA1

- Matrix Resin: Polyamide66

- Reinforcing Filler: Carbon fiber(10%)

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Superior Heat-Resistant PA66-LCF20: The Definitive Choice for High-Performance Auto Engine Covers

In the demanding world of automotive engineering, every component under the hood faces a relentless assault of heat, vibration, and chemical exposure. Ordinary materials falter, leading to compromised performance, warping, and premature failure.

For engineers and designers seeking a material that embodies resilience and reliability for critical applications like auto engine covers, the search ends with a superior advanced composite: PA66-LCF20.

This is not merely a plastic; it is a meticulously engineered solution where the foundational benefits of Polyamide sixty-six are radically transformed through integration with long carbon fiber technology.

The result is a material that establishes a new benchmark for performance, durability, and stability in the most challenging environments.

This comprehensive exploration delves into the reasons why PA66-LCF20 stands as the ultimate material selection for automotive professionals who refuse to compromise on quality, efficiency, or longevity in their engine bay assemblies.

Understanding the PA66-LCF20 Advantage for Automotive Applications

To fully appreciate the transformative impact of PA66-LCF20, one must first understand its fundamental composition and the synergistic relationship between its constituents. This knowledge reveals the scientific foundation behind its unmatched performance in creating reliable and high-performing auto engine covers.

The Robust Foundation of PA66-LCF20

At the heart of the PA66-LCF20 composite lies a high-grade Polyamide sixty-six matrix. This specific polymer is renowned throughout the automotive industry for its exceptional balance of properties.

It possesses an innate toughness and a notable resistance to a wide spectrum of chemicals, including oils, greases, and various fluids ubiquitous in engine compartments. Furthermore, this nylon base offers a good baseline of thermal resistance, allowing it to maintain integrity in the warm environments typical of automotive operation.

This robust polymeric foundation ensures that components fashioned from PA66-LCF20 will not degrade or succumb quickly when exposed to the harsh under-hood conditions, providing a dependable canvas for enhancement.

The Transformative Power of Long Carbon Fiber in PA66-LCF20

The true revolutionary character of PA66-LCF20 is unleashed by its reinforcement: a significant integration of long carbon fibers.

Unlike shorter fibers that offer modest, isotropic improvement, long carbon fibers are intricately woven throughout the nylon matrix, creating a continuous, networked internal structure.

This architecture is analogous to the steel reinforcement within a concrete pillar; it provides immense structural integrity and tensile strength. These long fibers dramatically elevate the stiffness of the PA66-LCF20 composite, effectively resisting deformation under sustained mechanical load and intense vibration.

They also profoundly enhance the dimensional stability and creep resistance, meaning a component manufactured from PA66-LCF20 will maintain its precise shape and fit over extended periods, even when subjected to constant elevated temperatures and stress.

This powerful union of the resilient nylon base and the robust carbon fiber network creates a synergistic effect, yielding a material with capabilities far surpassing those of conventional polymers.

The Hostile Environment of the Modern Engine Bay

The engine compartment of a modern vehicle is arguably one of the most punishing environments for any material.

It is a chamber of extremes, where components must perform flawlessly for thousands of hours. Auto engine covers, while sometimes perceived as primarily aesthetic, play a functional role in protecting underlying components, managing heat, and reducing noise.

They require a material with a very specific and robust profile to survive and thrive.

Relentless Thermal Cycling and Elevated Temperatures

A primary adversary for any under-hood component is heat. Auto engine covers are positioned in close proximity to the engine block, where they are continuously exposed to radiant and convective heat.

Temperatures fluctuate dramatically from cold starts to extended operation and back again, creating significant thermal cycling stress. This constant expansion and contraction can cause lesser materials to warp, crack, or lose their mechanical properties over time.

The exceptional heat-resistant nature of the PA66-LCF20 composite allows it to withstand these thermal cycles without compromising its form or function, ensuring a consistent fit and protective capability.

Constant Vibration and Mechanical Load

The internal combustion engine is a source of constant vibration and harmonic resonance. An auto engine cover must be rigid enough to not amplify noise or resonate excessively, yet possess enough inherent strength to withstand these vibrations without developing stress fractures.

Additionally, these covers often serve as mounting points for other components, adding mechanical load to the list of stresses. The high stiffness and superb strength inherent in PA66-LCF20 make it an ideal material for mitigating vibration and supporting ancillary loads without flexing or failing.

Exposure to Chemicals and Fluids

The engine bay is awash with potential chemical aggressors. Engine oil, transmission fluid, brake fluid, coolant, and various cleaning solvents can splash or drip onto components. Many polymers suffer from chemical attack, leading to embrittlement, swelling, or a catastrophic loss of structural integrity.

The outstanding chemical resistance offered by the PA66-LCF20 material ensures that accidental exposure to these fluids will not compromise the part, guaranteeing long-term reliability and appearance.

PA66-LCF20 in Action: A Scenario for Auto Engine Covers

Consider the development process for a new high-performance vehicle. The engineering team is tasked with designing an auto engine cover that is lightweight to improve efficiency, incredibly durable to last the life of the vehicle, and capable of withstanding the extreme conditions under the hood while maintaining a high-quality appearance.

Achieving Unmatched Performance and Reliability

By specifying PA66-LCF20 for the auto engine cover, the team immediately addresses their core challenges. The remarkable strength and stiffness imparted by the long carbon fibers ensure the cover will not warp or deflect under heat, maintaining precise clearance from moving parts.

Its exceptional vibration damping characteristics reduce overall engine bay noise, contributing to a quieter cabin experience.

The superior heat-resistant property of the PA66-LCF20 composite guarantees that the cover will not soften, sag, or discolor over time, preserving both function and aesthetics. Furthermore, the chemical resistance of PA66-LCF20 means that oil spills during routine maintenance will not cause staining or degradation, ensuring the engine bay retains its showroom look.

Enhancing Value and Long-Term Durability

The selection of PA66-LCF20 translates directly into enhanced value for both the manufacturer and the end consumer.

For the automaker, the processing characteristics of PA66-LCF20 allow for the production of complex, integrated designs that can reduce the number of parts and simplify assembly. For the vehicle owner, the unparalleled durability of an auto engine cover made from PA66-LCF20 means a component that is virtually maintenance-free and built to last, eliminating concerns about failure or replacement throughout the ownership experience.

This longevity and resilience underscore the smart investment represented by choosing PA66-LCF20 for demanding automotive applications.

Why Partner with Us for Your PA66-LCF20 Material Needs

Selecting the right material is a critical first step, but ensuring a supply of consistent, high-quality material is equally vital for your production success.

Unwavering Commitment to Quality and Consistency

We understand that your manufacturing process demands absolute predictability.

Our PA66-LCF20 is produced under meticulously controlled conditions to ensure perfect dispersion and alignment of the long carbon fibers within the polymer matrix.

This rigorous control guarantees uniform mechanical properties, exceptional surface quality, and reliable processing behavior in every single batch of PA66-LCF20 material you receive.

Technical Partnership and Expert Support

Our role extends beyond that of a mere supplier; we aspire to be your technical partner. Our team of material science experts is available to provide comprehensive support, from initial design consultation and advice on optimizing mold designs for PA66-LCF20 to troubleshooting processing parameters.

We are committed to helping you leverage the full potential of PA66-LCF20 to bring superior, reliable, and innovative automotive components to market.

Conclusion: Specify PA66-LCF20 for Uncompromising Automotive Excellence

In the relentless pursuit of automotive innovation and reliability, the choice of material is paramount.

The formidable challenges presented by the modern engine bay demand a solution that offers more than just basic functionality; they demand a material engineered for superiority.

PA66-LCF20 rises to meet this demand with an unparalleled combination of heat resistance, structural strength, vibrational damping, and chemical resilience. It empowers engineers to design auto engine covers and other under-hood components that are not only lightweight and strong but also built to endure for the long haul.

By specifying PA66-LCF20, you are not just choosing a polymer; you are investing in performance, durability, and peace of mind. Choose PA66-LCF20 for your next project and experience the definitive advantage in advanced automotive composites.

If you want to get more information about PA66-LCF10, you can visit our Youtube.

Click here to contact us.

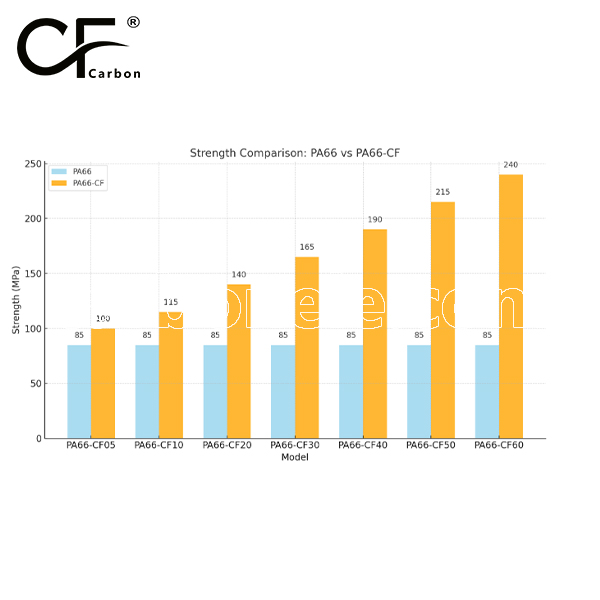

Strength between PA66 and PA66-CF

Compared to unreinforced PA66, PA66-CF (carbon fiber reinforced) offers significantly higher strength and stiffness. The addition of carbon fiber increases tensile and flexural strength, enhances dimensional stability, and reduces deformation under load. While standard PA66 provides good toughness and impact resistance, PA66-CF materials are better suited for structural and high-stress applications where superior mechanical performance is required.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.