Tired of Weak Plastics? Buy PP-LCF10 for Instant Strength

- Model number: PP-LCF-BAC1

- Matrix Resin: Polypropylene

- Reinforcing Filler: Carbon fiber(10%)

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Tired of Weak Plastics? Buy PP-LCF10 for Instant Strength

If you’ve ever faced cracking, warping, or structural failure in your plastic components, you’re not alone. Weak plastics compromise product integrity, lead to costly replacements, and cause avoidable frustration. That’s why engineers, designers, and manufacturers are making the switch to PP-LCF10, a high-performance polypropylene material reinforced with long carbon fibers.

Whether you’re designing automotive parts, industrial components, or durable consumer products, PP-LCF10 offers the kind of strength and stability that ordinary plastics simply cannot match. This product detail page will walk you through the essential reasons why PP-LCF10 is the solution you’ve been searching for.

Why Choose PP-LCF10 for Demanding Applications

PP-LCF10 is not your average polypropylene. It’s engineered specifically for situations where traditional plastics fail. Infused with long carbon fibers, this material transforms polypropylene into a structural-grade solution, combining light weight with mechanical reliability.

Where most plastics lose form under pressure or heat, PP-LCF10 holds firm. This enhanced stability makes it ideal for parts that must endure repeated mechanical load, thermal variation, or external impact.

Real-World Application: Automotive HVAC Mount Upgrade

Imagine this: a global automotive supplier was struggling with consistent failures in their HVAC mounting systems. The brackets, made from standard polypropylene, would deform under high temperatures and break after prolonged use.

After switching to PP-LCF10, the issue was resolved. The reinforced material handled the same stress environment without degradation. The end result was not only a stronger component, but also a longer-lasting and more cost-effective solution.

This specific scenario highlights why PP-LCF10 is more than a material—it’s a problem-solving tool that can be adapted across multiple industries.

What Makes PP-LCF10 Structurally Superior

Long Carbon Fiber Reinforcement

The inclusion of long carbon fibers significantly changes how PP-LCF10 performs. These fibers distribute mechanical stress evenly throughout the part, which reduces internal strain and improves dimensional retention over time.

Where traditional plastics might crack or buckle, PP-LCF10 maintains integrity under complex loading conditions. This is particularly valuable in mechanical assemblies where tolerances and stability are critical.

Stable Form Under Process Stress

Not only does PP-LCF10 perform well in use, but it also excels during processing. It offers excellent mold flow and part fill, making it compatible with various manufacturing techniques. The material also demonstrates strong resistance to warping and shrinkage, resulting in consistent, accurate part geometry.

This dimensional reliability translates to lower rejection rates, smoother assembly, and tighter product control for manufacturers.

Surface Quality Meets Structural Strength

Designed for Appearance-Sensitive Applications

Unlike other structural plastics that sacrifice aesthetics for strength, PP-LCF10 is designed to offer both. Its surface quality can be tailored to matte, semi-gloss, or textured finishes depending on product requirements.

That means PP-LCF10 is suitable for visible parts in automotive interiors, electronics housings, appliance components, and more. The material doesn’t just perform—it looks great doing it.

Functional Coatings and Custom Finishes

If your project demands additional functionality, PP-LCF10 can be customized with UV-resistant or scratch-resistant coatings. Whether you need a refined visual surface or added durability for external environments, this material delivers.

Industry Versatility and Use Cases

PP-LCF10 adapts to a wide range of industries due to its unique combination of mechanical strength, processing compatibility, and visual appeal.

Automotive Components

From HVAC brackets to interior panels and lightweight housings, PP-LCF10 is trusted in the automotive world where weight reduction and safety must coexist.

Industrial Fixtures and Tooling

In high-wear, high-load settings like industrial jigs or support brackets, PP-LCF10 holds up under repeated mechanical use, resisting deformation and surface damage.

Consumer Products and Appliances

Durability, especially in structural areas of consumer goods like washing machines or kitchen devices, is enhanced through PP-LCF10 without sacrificing the clean finish needed for visible surfaces.

Your Trusted Source for PP-LCF10

Choosing the right supplier for PP-LCF10 is as important as choosing the right material. Our facility combines advanced compounding capabilities with strict quality control to ensure every batch of PP-LCF10 meets high-performance standards.

Our clients include manufacturers in the automotive, home appliance, and industrial tooling sectors. With a strong focus on customer success, we offer tailored grades, technical support, and responsive after-sales service.

FAQs About PP-LCF10

What is PP-LCF10 used for?

PP-LCF10 is widely used in structural applications where traditional plastics fail, such as automotive brackets, electronic casings, and industrial fixtures.

Can I mold PP-LCF10 using regular equipment?

Yes. PP-LCF10 is designed for compatibility with standard injection molding processes, allowing for smooth integration into your current production lines.

Is PP-LCF10 suitable for outdoor or high-temperature use?

Absolutely. With proper formulation, PP-LCF10 can handle environmental stressors like temperature swings and UV exposure.

How is PP-LCF10 different from standard polypropylene?

PP-LCF10 contains long carbon fibers, giving it significantly enhanced strength, rigidity, and dimensional stability compared to unreinforced polypropylene.

Do you offer support for PP-LCF10 applications?

Yes. We provide full technical documentation, material selection assistance, and after-sales support to ensure successful product development and use.

Final Thoughts: Strength You Can Rely On

If you’re tired of components that break, warp, or fall short in demanding applications, it’s time to upgrade. PP-LCF10 offers the strength of engineered composites, the processability of plastics, and the finish quality that modern applications demand.

Don’t let weak materials compromise your product. Choose PP-LCF10 and build with confidence.

If you want to get more information about PP-LCF10, you can visit our Youtube.

Click here to contact us.

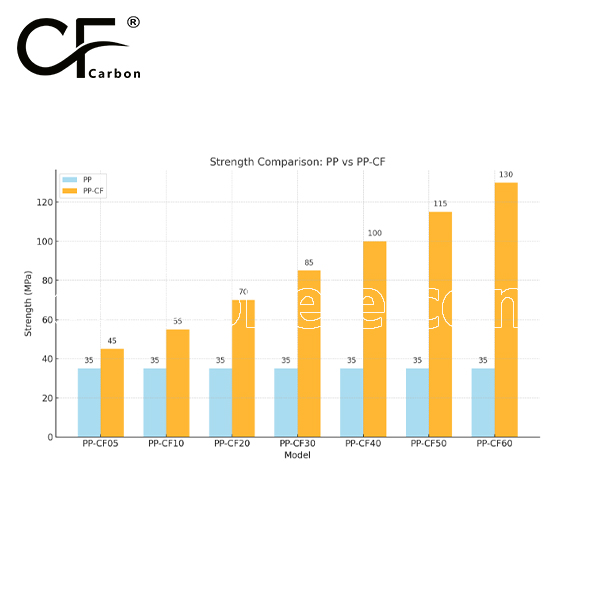

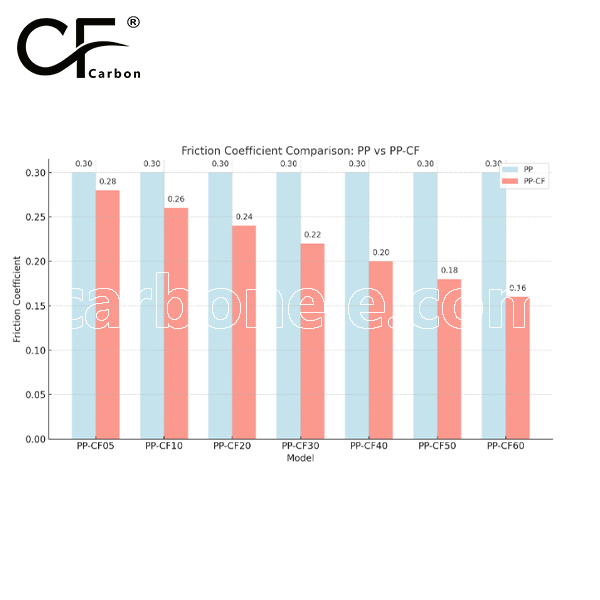

Strength between PP and PP-CF

PP-CF exhibits significantly higher strength and stiffness compared to unreinforced PP due to the addition of carbon fiber reinforcement. While standard polypropylene (PP) is known for its flexibility and impact resistance, it lacks the rigidity and load bearing capacity required for high-performance applications. In contrast, PP-CF enhances tensile strength, flexural modulus, and dimensional stability, making it more resistant to deformation under mechanical stress. This improved performance allows PP-CF to be used in applications where higher strength-to-weight ratio and structural integrity are critical.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.