Chemical Resistant TPU-LCF60 for Fluid Handling Systems

TPU-LCF60 is an ultra-high-strength thermoplastic polyurethane reinforced with 60% long carbon fiber, delivering metal-like rigidity, superior heat resistance, and exceptional dimensional stability—while retaining TPU’s shock absorption and fatigue resilience. Ideal for extreme-load, semi-structural applications in automotive, robotics, aerospace, and ruggedized systems.

- Model number: TPU-LCF-BCA6

- Matrix Resin: Thermoplastic polyurethane (TPU)

- Reinforcing Filler: Carbon fiber

- Appearance: Granules

- Grade: Injection/extrusion grade

- Packaging: 25kgs/bag

Introduction to TPU-LCF60

TPU-LCF60 is a high-performance thermoplastic polyurethane reinforced with a substantial carbon fiber content, engineered for exceptional strength, impact resistance, and long-term durability. Known for its unique balance of flexibility and structural integrity, it is an ideal choice for industries where performance under stress is critical. The material excels in environments requiring both resilience to physical forces and resistance to wear, making it a preferred option for manufacturing advanced sports gear.

Its exceptional properties stem from the synergy between a robust TPU matrix and high levels of carbon fiber reinforcement. This combination results in a lightweight yet extremely tough material that can handle repeated impacts without compromising shape or performance. Whether for professional sports equipment, protective gear, or components in demanding recreational products, it delivers reliable results over extended use.

Why TPU-LCF60 is the Future of Sports Gear

Sports equipment must meet the demanding standards of athletes who expect their gear to withstand rigorous use while maintaining comfort and performance. It addresses these challenges with a material that absorbs impact forces while retaining its shape. Its mechanical stability and abrasion resistance make it an outstanding candidate for parts subject to constant motion, friction, and stress.

In addition, its lightweight nature contributes to enhanced agility and comfort for the wearer or user. This reduction in unnecessary weight allows athletes to focus entirely on performance rather than dealing with heavy or cumbersome gear. Combined with the material’s aesthetic flexibility, designers have the freedom to create functional products without sacrificing style.

Application Example: Protective Sports Helmet Shell

One of the most prominent uses of TPU-LCF60 in the sports sector is in the creation of high-performance helmet shells for activities such as cycling, skateboarding, snowboarding, and contact sports. These helmets require a perfect blend of toughness and shock absorption to safeguard athletes from potential injuries.

TPU-LCF60 excels in this application due to its superior energy-dissipating properties. Upon impact, the carbon fiber-reinforced TPU structure efficiently distributes force, minimizing localized stress and reducing the risk of cracks or failure. This allows helmets to offer reliable protection over repeated impacts, extending their service life and maintaining safety standards without frequent replacement.

Properties That Make TPU-LCF60 Stand Out

Exceptional Impact Resistance

The core benefit of TPU-LCF60 lies in its ability to absorb and dissipate high levels of kinetic energy. This makes it ideal for sports equipment subjected to sudden shocks, collisions, or drops.

Superior Abrasion Resistance

In fast-paced sports, friction and wear are constant threats to equipment longevity. Its resistance to abrasion ensures components retain their performance characteristics even under extreme use conditions.

Lightweight Strength

Despite its enhanced durability, it remains remarkably lightweight, improving user comfort and mobility. This balance between weight and strength is especially valuable in wearable sports gear.

Flexibility with Structural Stability

The material offers controlled flexibility, allowing it to bend under pressure without permanent deformation. This flexibility works in harmony with the stiffness provided by carbon fibers, resulting in a resilient yet form-stable structure.

Advantages of TPU-LCF60 in Sports Applications

Extended Product Life

Using TPU-LCF60 in sports gear significantly extends the lifespan of products. Athletes can rely on consistent performance without worrying about premature wear or breakage.

Enhanced Safety

The impact resistance of TPU-LCF60 directly contributes to better user protection. Whether used in helmets, padding, or guards, it helps mitigate injury risks.

Design Freedom

Manufacturers benefit from TPU-LCF60’s ease of processing and compatibility with intricate designs. This allows for innovative shapes and features without compromising durability.

Consistent Performance in Various Conditions

TPU-LCF60 maintains its mechanical properties across a wide range of environmental conditions, ensuring reliable performance in both hot and cold climates.

TPU-LCF60 in Specific Sports Equipment

Helmet Shells

TPU-LCF60 helmet shells are a benchmark in protection and durability, capable of withstanding repeated impacts while maintaining their structural integrity.

Shin Guards and Knee Pads

Sports gear such as shin guards and knee pads made from TPU-LCF60 offer superior protection from strikes and collisions without adding unnecessary weight.

Skateboard and Scooter Deck Overlays

The material’s abrasion resistance makes it perfect for overlays on skateboard and scooter decks, ensuring long-lasting grip and structural strength.

Snowboard Bindings

In cold-weather sports, TPU-LCF60 provides reliable performance without becoming brittle, making it ideal for components like snowboard bindings that must handle repeated stress and flexing.

Why TPU-LCF60 Surpasses Traditional Materials

Compared to metals, TPU-LCF60 offers reduced weight, better flexibility, and no risk of rust or corrosion. When compared to unreinforced polymers, it delivers vastly superior impact strength, stiffness, and wear resistance. This gives athletes and manufacturers a clear advantage when choosing materials for high-performance gear.

Beyond Sports: Other Potential Applications

While TPU-LCF60 is an outstanding choice for sports equipment, its properties make it equally suitable for other industries. From industrial machine couplings to automotive components and protective casings for electronics, TPU-LCF60’s versatility ensures it can meet performance requirements across diverse sectors.

Conclusion: TPU-LCF60 as a Sports Gear Game-Changer

TPU-LCF60 offers the perfect combination of strength, flexibility, and impact resistance for high-performance sports equipment. Its proven ability to enhance safety, extend product lifespan, and maintain performance under stress makes it a valuable asset for both athletes and manufacturers. By integrating TPU-LCF60 into sports gear design, brands can deliver products that perform exceptionally in the real world, inspiring confidence in users and standing out in a competitive market.

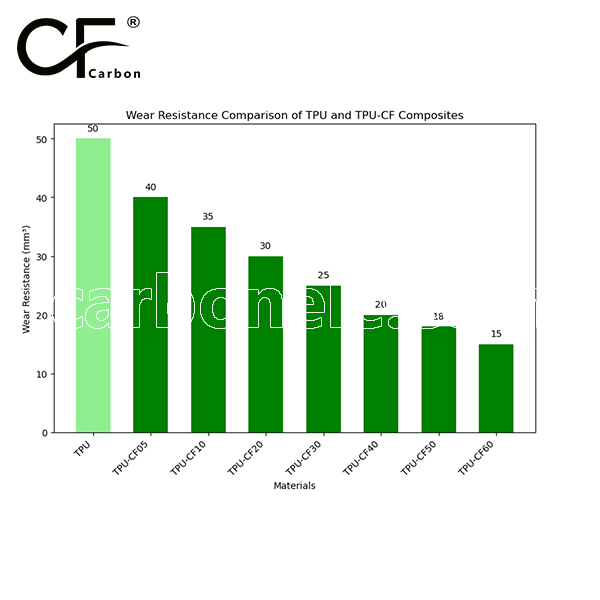

Friction coefficient of PA12-LCF

The friction coefficient of TPU is typically between 0.3 and 0.5, while TPU-CF, with added carbon fiber, lowers the friction coefficient to between 0.2 and 0.4. The smaller the value, the better the wear resistance. Therefore, TPU-CF generally offers better wear resistance than pure TPU, especially under high-load conditions.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

How can I contact the manufacturer of a product that interests me?

When you find a product you are interested in, you can contact the manufacturer directly by sending an email and we will get back to you as soon as possible.

-

How do I find the products that interest me?

All you need to do is enter the keyword, product name in the search window and press the Enter key on your keyboard. Your search results page will then be displayed. You can also search within the product category pages on the home page. Each category is divided into subcategories, allowing you to refine your search and find products that interest you.

-

Where will I find a buying guide?

Please contact our after-sales service directly and we will provide you with a comprehensive operating guide.

-

What are CF Reinforced Thermoplastic Composites?

CF Reinforced Thermoplastic Composites are materials where carbon fibers are incorporated into a thermoplastic matrix. They combine the strength and stiffness of carbon fibers with the processability and recyclability of thermoplastics. For instance, they are used in automotive parts like bumper beams.

-

What are the benefits of CF Reinforced Thermoplastic Composites over traditional composites?

The key benefits include faster production cycles, easier recyclability, and better impact resistance. They also offer design flexibility. An example is in the manufacturing of consumer electronics casings where complex shapes can be achieved more easily.

-

How are CF Reinforced Thermoplastic Composites processed?

Common processing methods include injection molding, extrusion, and compression molding. Injection molding is widely used for mass production. For example, in the production of small components for the medical industry.

-

What industries use CF Reinforced Thermoplastic Composites?

They are utilized in aerospace, automotive, medical, and sports equipment industries. In aerospace, they can be found in interior components. In the medical field, they might be used in prosthetics.

-

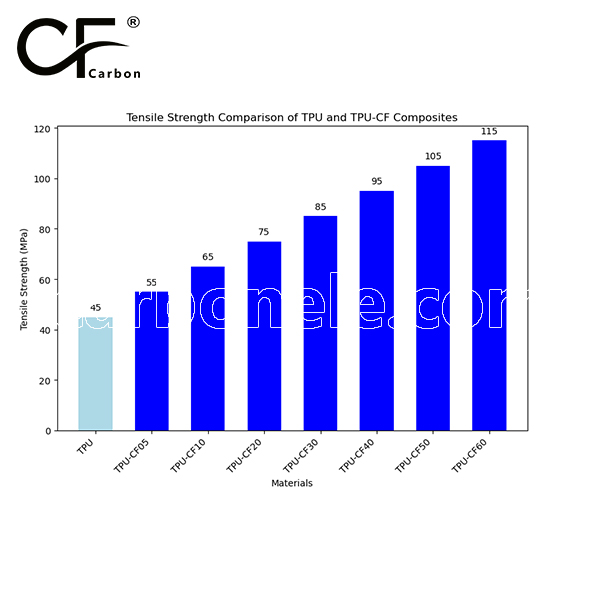

How does the carbon fiber content affect the properties of the composites?

Higher carbon fiber content generally leads to increased strength and stiffness but may reduce ductility. A moderate content is often balanced for specific applications. For example, a higher content might be preferred in structural parts of a race car.

-

What are the challenges in using CF Reinforced Thermoplastic Composites?

Challenges include higher material costs, complex processing equipment requirements, and ensuring uniform fiber dispersion. Issues with adhesion between the fibers and the matrix can also arise. An example is in achieving consistent quality in large-scale production.