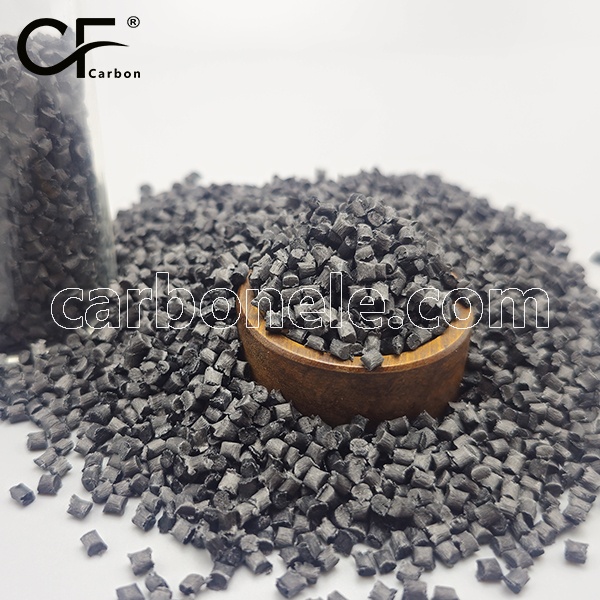

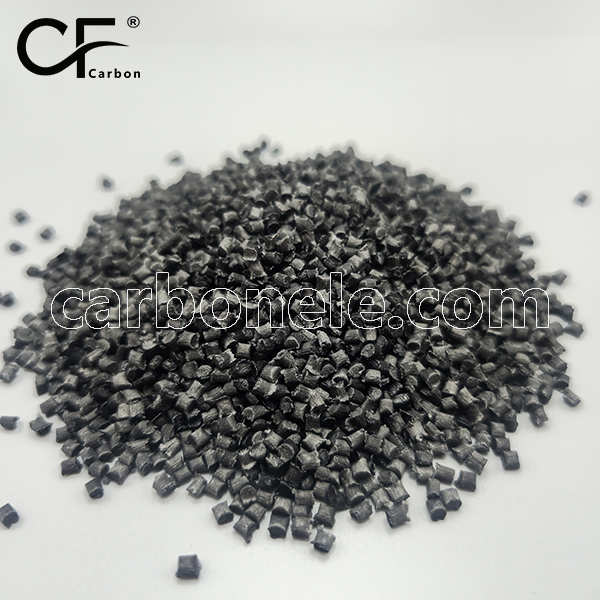

The Role and Uses of PC CF Composites

The PC CF Reinforced Composites have several notable functions. They offer enhanced mechanical strength and rigidity, allowing them to withstand heavy loads and impacts. Their excellent heat resistance enables them to perform well in high-temperature environments.

In terms of applications, they are commonly used in the automotive industry for manufacturing lightweight yet strong components like body panels and structural parts. They are also utilized in the production of electronic devices' casings due to their good electrical insulation and mechanical properties. Additionally, they find use in aerospace for critical parts that require high performance and reliability.

Product By Features

High-performance PC-CF20 Composite for Auto Hea...

PC-CF20 carbon fiber reinforced polycarbonate composite material for auto headlight mounts. High-performance engineering thermoplastic with superior strength, impact resistance and dimensional stability. Ideal for automotive lighting components.

Learn More

Robust PC-CF10 Panel – Industrial Strength

Robust PC-CF10 carbon fiber panels deliver industrial-grade strength, impact resistance & dimensional stability for machine guards, control panels & enclosures. Durable, lightweight & chemical-resistant—engineered for harsh environments

Learn More

PC CF15 Raw Materials for 3D Printing Filaments

1.15% carbon fiber – Enhanced strength & printability 2.85MPa tensile strength -120% stronger than pure PC 3.82% light transmittance – Maintains optical clarity 4.0.5% shrinkage – Minimal warpage 5.100mm/s print speed – High-efficiency production

Learn More

CF40 PC Plastics for Large Format 3D Printing P...

1. 40% carbon fiber reinforced -Near-metallic strength 2. 155℃ HDT -50℃ higher than standard PC 3. 150MPa tensile strength -50% of aluminum’s strength 4. 0.2% max shrinkage -Ultra-low warpage 5. 60MPa layer strength -Superior interlayer bonding

Learn More

PC CF30 Raw Materials for Fused Granulate Fabri...

1. 30% carbon fiber reinforced -Enhanced strength &stiffness 2. 148°C heat deflection – Automotive-grade thermal stability 3. 125MPa tensile strength -High mechanical performance 4. 1.8×10-5/°℃ CTE- Low-warpage printing 5. 52MPa interlayer strength -Superior FGF bonding

Learn More

Intermediate Temperature PC CF30 Pellets for Ad...

1.145°C HDT-40℃ higher than standard PC 2.120MPa tensile strength -250% stronger than unfilled PC 3.12-14GPa flex modulus – <8% anisotropy 4.0.25% max shrinkage – 70% less warpage 5.50MPa layer strength -near injection-molding performance

Learn More

High Impact PC-CF20 Granules for LFAM

High Impact PC-CF20 Granules Features: * 65kJ/m² impact strength * 8-10GPa flexural modulus * 1.35g/cm³ lightweight density * 0.3mm/m printing accuracy * 45MPa layer bonding strength

Learn More

PC-CF30 Is 3X Stiffer Than Standard PC—Here’s W...

Discover the advantages of PC-CF30, a carbon fiber reinforced polycarbonate with superior stiffness and heat resistance. Ideal for automotive housings, industrial enclosures, and structural plastic parts.

Learn More

Modified Polycarbonate PC CF20 for Fused Granul...

Modified Polycarbonate PC CF20 for FGF: 1️⃣ Tensile Strength: ~120 MPa (vs. ~65 MPa for neat PC) 2️⃣ Heat Resistance (HDT): ~145°C (vs. ~130°C for standard PC) 3️⃣ Shrinkage/Warpage: 0.3% (vs. 1.2% for unfilled PC) 4️⃣ Shear Viscosity: 30% lower than neat PC (improves FGF flow) *Ideal for large-format 3D printing with high strength & stability.*

Learn More

PC-CF60 engineering plastics

PC-CF60 is a high performance polycarbonate composite reinforced with 60% carbon fiber, offering maximum stiffness, strength, and wear resistance. With a tensile strength of ≥170 MPa and HDT of approx. 200°C, it ensures exceptional durability in high-stress and extreme performance applications. Its low moisture absorption and superior dimensional stability make…

Learn More

Thermoplastic polymer processing PC-CF50

PC-CF50 is a 50% carbon fiber reinforced polycarbonate composite, offering maximum strength, stiffness, and wear resistance. With a tensile strength of ≥155 MPa, flexural strength of ≥220 MPa, and heat deflection temperature of approx. 190°C, it is ideal for structural components, automotive parts, and high-performance applications. Its low moisture absorption…

Learn More

PC-CF40 thermoplastic polymer processing

PC-CF40 is a 40% carbon fiber-reinforced polycarbonate composite, offering exceptional strength, stiffness, and wear resistance. With a tensile strength of ≥140 MPa, flexural strength of ≥200 MPa, and heat deflection temperature of approx. 180°C, it is ideal for structural components, automotive parts, and high-performance applications. Its low moisture absorption and…

Learn MoreProduct Feature Box

WEAR RESISTANCE

CONDUCTIVE MATERIALS

HIGH STRENGTH

ANTI STATIC

SCRATCH RESISTANCE

ABRASION RESISTANCE

ECO FRIENDLY

LIGHT WEIGHT

Company Advantage

Excellent After-sales Service

Carbon (Xiamen) New Material offers all-round, prompt, and professional after-sales support. A dedicated team responds within 24 hours. They solve problems remotely or on-site and provide installation and maintenance training. Feedback is used to improve service. It also offers regular follow-ups to ensure customer satisfaction in the long term.

Rich Industry Experience

Years of involvement give Carbon (Xiamen) New Material production and trade knowledge. It supplies to major projects, enhancing skills and reputation. Active in global events, it keeps up with trends and gains information for growth. It also leverages this experience to anticipate market changes and adapt accordingly.

Export Qualifications and Certifications:

Carbon (Xiamen) New Material has export qualifications and international certifications like ISO 9001 and AS9100. These boost product recognition and competitiveness, opening doors to high-end markets and various industries. It constantly works towards obtaining more certifications to expand its market reach.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

What is the main advantage of PC CF Reinforced Composites over traditional materials?

It offers superior mechanical strength and lightweight properties, making it more suitable for demanding applications.

-

How does PC CF Reinforced Composites perform in extreme temperatures?

It has good heat resistance and can maintain its properties in a wide temperature range.

-

Can Polycarbonate Carbon Fiber Reinforced Composites be recycled?

Yes, but the process may be more complex compared to some other materials.

-

What industries commonly use PC CF Reinforced Composites?

Automotive, aerospace, electronics, and medical industries are among the common users.

-

Are there any limitations to using PC CF Reinforced Composites?

The cost can be relatively high, and the manufacturing process requires advanced techniques.

-

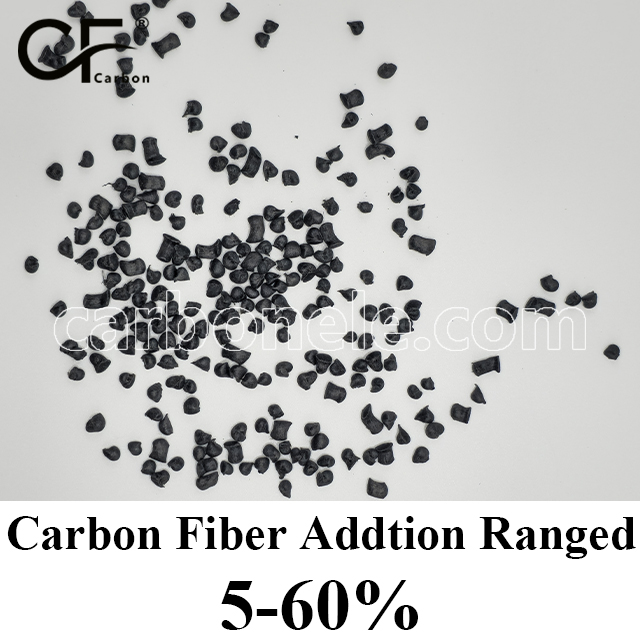

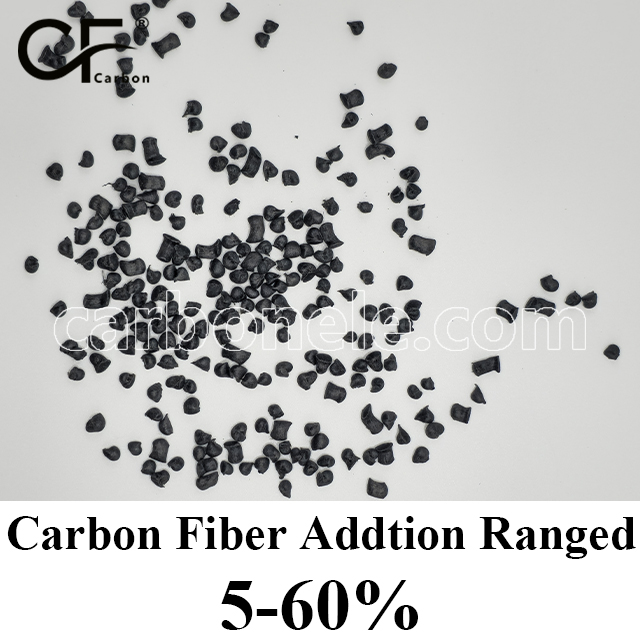

How does the addition of carbon fibers affect the properties of PC?

It significantly increases strength, stiffness, and thermal stability.

-

What are the typical processing methods for PC CF Reinforced Composites?

Injection molding, extrusion, and compression molding are often employed.