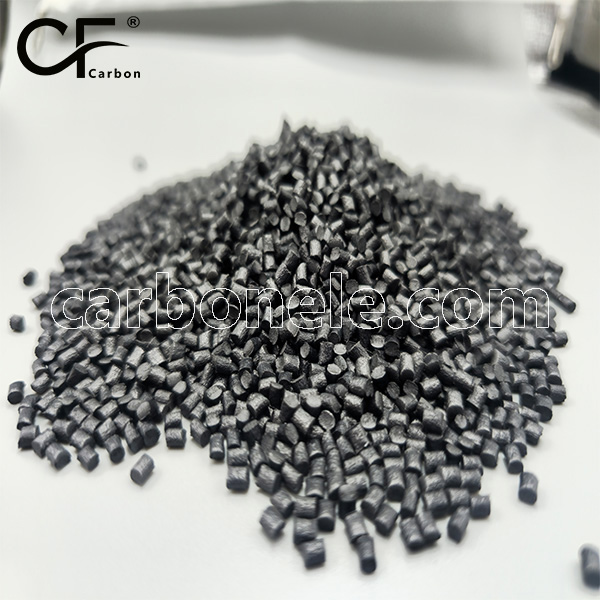

PEEK CF: Transforming Industries with Excellence

The features of PEEK CF Reinforced Composites include: 1. Exceptional mechanical strength and stiffness, allowing it to handle heavy loads and mechanical stress. 2. Outstanding heat resistance, capable of maintaining its properties at high temperatures. 3. Excellent chemical resistance, enabling it to withstand various corrosive substances. 4. Low coefficient of friction, reducing wear and tear in moving parts. 5. Good dimensional stability, ensuring precise and consistent performance.

The main applications of PEEK CF Reinforced Composites are as follows: 1. In the aerospace industry for manufacturing lightweight and high-strength components such as aircraft engine parts and structural elements. 2. In the automotive sector for making parts that require high performance and heat resistance, like engine components and transmission parts. 3. In the medical field for producing implants and prosthetics due to its biocompatibility and mechanical properties. 4. For industrial machinery parts that endure harsh conditions and heavy usage. 5. In the electronics industry for components that need excellent thermal management and mechanical stability.

Product By Features

Tough PEEK-CF20 | Ideal Semiconductor Fixtures

PEEK-CF20 carbon fiber reinforced thermoplastic offers exceptional strength and thermal stability for semiconductor fixtures, aerospace components, and medical applications. Request a quote today.

Learn More

Durable PEEK-CF10 Polymer for Medical Implants

PEEK-CF10 carbon-reinforced medical polymer delivers strength & biocompatibility for spinal/orthopedic implants. MRI-compatible, lightweight, and chemically inert for enhanced patient outcomes

Learn More

PEEK CF10 Composite for High-Pressure Tubing Ap...

PEEK CF10 is a high-performance polyether ether ketone composite reinforced with 10% carbon fiber, delivering superior mechanical strength, thermal stability and chemical resistance – perfect for precision components requiring exceptional durability in extreme operating conditions.

Learn More

Fiber Pull‑out Risk: How Bonding in PEEK-CF10 P...

PEEK‑CF10 eliminates fiber pull‑out to keep composite parts intact. Discover its superior bonding, heat and chemical resistance, and light weight for high‑reliability designs.

Learn More

PEEK CF30 High-Performance Plastic for Aerospace

1.Conductive PEEK CF30: High-Performance Engineering Plastic for Demanding Ap...

Learn More

Self-lubricating PEEK CF10 PTFE Composite Raw M...

**Self-lubricating PEEK CF10 PTFE composite** combines carbon fiber’s strength with PTFE’s low friction (0.1–0.3), enabling dry operation. It resists wear, chemicals, and temperatures up to 300°C (572°F), with excellent dimensional stability (<0.1% moisture absorption). Ideal for high-load bearings, seals, and gears in aerospace, automotive, and harsh industrial applications, outperforming metals…

Learn More

Resistance Value 10E6-10E10 PEEK CF Blends for ...

PEEK CF blends (Polyetheretherketone-Carbon Fiber) in antistatic tweezers indicates controlled electrostatic discharge (ESD) protection, making them suitable for precision handling in static-sensitive environments (e.g., electronics, semiconductor packaging).

Learn More

Granular Conductive PEEK CF30 Engineering Plast...

Non-stick Easy Demoulding CF20 PEEK offers high strength, rigidity, and anti-fatigue property. It has high heat resistance, low thermal expansion, and chemical stability, along with non-stick and easy demoulding features for optimal separation claw performance.

Learn More

Non-stick Easy Demoulding CF20 PEEK for Separat...

Non-stick Easy Demoulding CF20 PEEK offers high strength, rigidity, and anti-fatigue property. It has high heat resistance, low thermal expansion, and chemical stability, along with non-stick and easy demoulding features for optimal separation claw performance.

Learn More

PEEK-PTFE-CF Compounds for Printer Separation C...

PEEK-PTFE-CF Compounds offer high wear resistance, low friction, excellent chemical and thermal stability, superior strength, dimensional stability, low moisture absorption, enhanced load-bearing capacity, non-stick properties, and suitability for high-performance engineering applications.

Learn More

Heat-stable Anti-static PEEK CF10 Plastic Raw M...

Heat-stable and anti-static PEEK CF10 pellets, with 10% CF reinforcement, offer good strength, wear resistance, chemical resistance, and are easy to process, lightweight and dimensionally stable.

Learn MoreProduct Feature Box

ANTI STATIC

SCRATCH RESISTANCE

ABRASION RESISTANCE

ECO FRIENDLY

LIGHT WEIGHT

HIGH STRENGTH

CONDUCTIVE MATERIALS

WEAR RESISTANCE

Company Advantage

Efficient Supply Chain Management

Carbon (Xiamen) New Material has a mature supply chain that ensures raw material supply and on-time product delivery. Close ties with global suppliers guarantee quality. Cooperation with logistics experts ensures fast transportation. Real-time tracking predicts and resolves issues. The company also maintains a buffer stock of critical raw materials to mitigate supply chain disruptions and has contingency plans in place to handle unforeseen circumstances promptly.

Export Qualifications and Certifications

Carbon (Xiamen) New Material has export qualifications and international certifications like ISO 9001 and AS9100. These boost product recognition and competitiveness, opening doors to high-end markets and various industries. It is constantly working towards obtaining additional certifications and adhering to the latest industry standards to expand its market presence and meet the evolving demands of global customers.

Advanced Production Technology

Carbon (Xiamen) New Material is equipped with state-of-the-art carbon fiber composite production processes and advanced equipment. It has highly automated layup devices for precise fiber control, ensuring mechanical property consistency. Advanced curing methods like vacuum-assisted or autoclave curing improve efficiency and product quality. The company also regularly invests in research and development to introduce innovative production techniques, enhancing its ability to meet diverse customer needs and stay ahead in the competitive market.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

What Are PEEK CF Reinforced Composites?

PEEK CF Reinforced Composites are advanced materials combining PEEK and carbon fibers for enhanced properties.

-

What is the main advantage of PEEK CF Reinforced Composites?

It offers a combination of high strength, excellent heat resistance, and chemical resistance.

-

How does the addition of carbon fibers enhance PEEK?

Carbon fibers increase the mechanical properties and improve the dimensional stability.

-

In which industries are PEEK CF Reinforced Composites commonly used?

Aerospace, automotive, medical, electronics, and industrial machinery.

-

Are PEEK CF Reinforced Composites suitable for high-temperature environments?

Yes, they have excellent heat resistance and can perform well at elevated temperatures.

-

What is the cost of PEEK CF Reinforced Composites compared to other materials?

It is relatively expensive, but its superior properties justify the cost in specific applications.

-

How difficult is it to process PEEK CF Reinforced Composites?

Processing can be challenging and requires specialized equipment and techniques.

-

Can PEEK CF Reinforced Composites be recycled?

To some extent, but the process is complex and not as straightforward as some other materials.

-

What are the typical failure modes of PEEK CF Reinforced Composites?

Fatigue, impact damage, and delamination can occur under certain conditions.

-

How do environmental factors affect the performance of PEEK CF Reinforced Composites?

Moisture and UV radiation can have minimal impact, but extreme conditions may cause some degradation.

-

Are there any limitations to the use of PEEK CF Reinforced Composites?

The high cost and complex processing can be limitations in some cases.