Unlocking the Mysterious Power of PPS LCF Composites

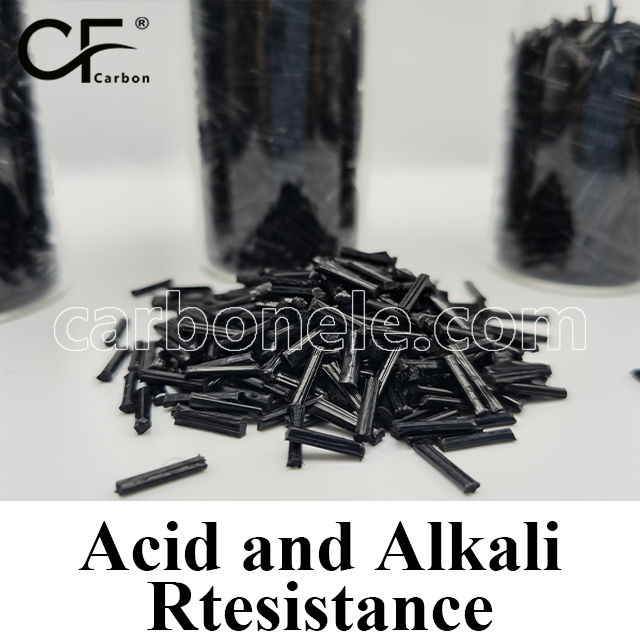

PPS LCF Reinforced Composites is a type of high-performance composite material. PPS, or polyphenylene sulfide, is a special engineering plastic with excellent performance. It inherently has outstanding heat resistance, chemical corrosion resistance, flame retardancy, and good electrical properties. "LCF" represents long carbon fibers. When long carbon fibers are combined with PPS to form PPS LCF Reinforced Composites, a synergistic effect occurs, greatly enhancing the material's performance. In terms of mechanical properties, this composite material has extremely high strength and stiffness. Compared to unreinforced PPS, its tensile strength, bending strength, and impact strength are significantly improved. This enables it to withstand greater loads and stresses, making it suitable for manufacturing components that operate under harsh conditions. At the same time, the addition of long carbon fibers also improves the thermal conductivity of PPS, making it perform well in applications with high heat dissipation requirements, such as the housings and heat sinks of electronic devices.

PPS LCF Reinforced Composites also has a low coefficient of thermal expansion and good dimensional stability, and can still maintain good performance in environments with large temperature variations. Due to these excellent performance characteristics, PPS LCF Reinforced Composites has broad application prospects in many fields such as aerospace, automobiles, and electronics. For example, in the aerospace field, it can be used to manufacture structural components of aircraft; in the automotive industry, it can be used for components around the engine; in the electronics field, it is suitable for packaging and heat dissipation components of high-power electronic components.

Product By Features

PPS-LCF10 Superior 10% CF for Chemical Equipment

PPS-LCF10 is a high-performance thermoplastic composite with 10% carbon fiber, delivering superior strength, chemical resistance, and thermal stability for demanding chemical equipment applications. Ideal for pumps, valves, and structural parts, PPS-LCF10 ensures long-term reliability and precise performance even in harsh environments. With its lightweight structure, high stiffness, and compatibility with…

Learn More

PPS-LCF60 for High Performance 3D Printing

PPS-LCF60 is a top tier thermoplastic reinforced with 60% long carbon fiber, offering extreme stiffness (~26 GPa), high tensile strength (≥ 240 MPa), and exceptional thermal stability (up to 260 °C). Designed for metal replacement in the harshest environments, it excels in aerospace, automotive, industrial, and electronic structural applications.

Learn More

PPS-LCF50 Precision Components

PPS-LCF50 is a high performance thermoplastic reinforced with 50% long carbon fiber, delivering exceptional strength (≥ 220 MPa), stiffness (~22 GPa), and thermal stability up to 250 °C. Ideal for metal replacement, it excels in structural, high load, and chemically harsh environments across automotive, aerospace, and industrial applications.

Learn More

PPS-LCF40 Composites for Automotive Parts

PPS-LCF40 is a high performance thermoplastic reinforced with 40% long carbon fiber, delivering exceptional stiffness, tensile strength (≥ 200 MPa), and thermal stability up to 240 °C. Ideal for metal replacement in high load, high temperature, and chemically aggressive environments, it excels in automotive, aerospace, and industrial structural applications.

Learn More

high performance PPS-LCF30 additive manufacturing

PPS-LCF30 is a high performance thermoplastic reinforced with 30% long carbon fiber, offering exceptional stiffness, tensile strength, and dimensional stability. It performs reliably in high load, high temperature (up to 230 °C), and chemically aggressive environments, making it ideal for metal replacement in automotive, aerospace, and industrial applications.

Learn More

Lightweight Structural Components PPS-LCF20

PPS-LCF20 is a high-performance thermoplastic reinforced with 20% long carbon fiber, offering superior stiffness, tensile strength, and fatigue resistance compared to lower fiber grades. It maintains excellent dimensional stability, thermal resistance (up to 220 °C), and chemical durability in demanding environments, making it ideal for structural components in automotive, aerospace, and…

Learn More

PPS-LCF10 for aerospace applications

PPS-LCF10 is a high performance thermoplastic reinforced with 10% long carbon fiber, offering enhanced strength, stiffness, and fatigue resistance compared to short fiber grades. It maintains excellent thermal stability (up to 200 °C) and chemical resistance in harsh environments, making it ideal for lightweight structural parts in automotive, aerospace, and industrial…

Learn More

High temperature resistance PPS-LCF60 composite...

PPS-LCF60 is a high-performance engineering plastic with 60% carbon fiber reinforcement, offering exceptional strength, rigidity, thermal stability, and chemical resistance. It is ideal for extreme load-bearing, high-temperature, and chemically harsh environments in industries such as aerospace, automotive, and manufacturing.

Learn More

PPS-LCF50 high strength composite material

PPS-LCF50 is a high-performance engineering plastic with 50% carbon fiber reinforcement, offering exceptional strength, rigidity, thermal stability, and chemical resistance. It is ideal for extreme load-bearing, high-temperature, and chemically harsh environments in industries such as aerospace, automotive, and manufacturing.

Learn More

High strength PPS-LCF40 composite material

PPS-LCF40 is a high-strength, thermally stable engineering plastic reinforced with 40% carbon fiber. It offers exceptional performance in extreme temperatures (up to 300°C) and harsh chemical environments, making it ideal for high-stress applications in automotive, aerospace, and industrial sectors.

Learn More

High strength composite material PPS-LCF30

PPS-LCF30 is a high-performance plastic reinforced with 30% carbon fiber, offering superior strength, thermal stability, and chemical resistance. Ideal for high-load, high-temperature, and chemical environments, it is commonly used in automotive, industrial, electronics, and aerospace applications.

Learn More

Composite Materials PPS-LCF20 High-Strength

PPS-LCF20 is a high-performance material with 20% carbon fiber, offering enhanced stiffness, strength, and thermal stability. It’s ideal for automotive, industrial, and aerospace applications requiring high mechanical stress, heat resistance, and chemical durability.

Learn MoreProduct Feature Box

ABRASION RESISTANCE

ECO FRIENDLY

LIGHT WEIGHT

WEAR RESISTANCE

SCRATCH RESISTANCE

ANTI STATIC

HIGH STRENGTH

CONDUCTIVE MATERIALS

Company Advantage

Professional R & D Team

Carbon (Xiamen) New Material has a team of experienced material scientists, engineers, and technical experts. They innovate and improve products. Material scientists enhance interfaces, engineers optimize designs, and experts use tech for monitoring and efficiency. The team actively participates in industry conferences and workshops, fostering a culture of learning and knowledge sharing, which leads to continuous improvement in product development and process optimization.

Cost Advantage

Through process optimization, strategic raw material purchasing, and large-scale production, Carbon (Xiamen) New Material reduces costs. Lean production reduces waste. Long-term supplier partnerships get better prices. Automation lowers labor costs, enhancing price competitiveness. Additionally, it implements effective cost management strategies and continuously evaluates its cost structure to identify further savings opportunities without sacrificing product quality or customer service.

Export Qualifications and Certifications

Carbon (Xiamen) New Material has export qualifications and international certifications like ISO 9001 and AS9100. These boost product recognition and competitiveness, opening doors to high-end markets and various industries. It is constantly working towards obtaining additional certifications and adhering to the latest industry standards to expand its market presence and meet the evolving demands of global customers.

Efficient Supply Chain Management

Carbon (Xiamen) New Material has a mature supply chain that ensures raw material supply and on-time product delivery. Close ties with global suppliers guarantee quality. Cooperation with logistics experts ensures fast transportation. Real-time tracking predicts and resolves issues. The company also maintains a buffer stock of critical raw materials to mitigate supply chain disruptions and has contingency plans in place to handle unforeseen circumstances promptly.

Frequently Asked Questions

Carbon (Xiamen) New Material Co., Ltd. aims to provide buyers with "one-stop" worry-free high-quality services. Here you can find all information about carbon fiber engineering plastics. If you still have questions, please send us an email for consultation!

-

Question 1: What are the main advantages of PPS LCF Composites?

Answer: PPS LCF Composites offer superior mechanical strength, excellent heat resistance, low thermal expansion, and good chemical resistance.

-

Question 2: In which industries are PPS LCF Composites commonly used?

Answer: They are commonly used in aerospace, automotive, electronics, and industrial machinery industries.

-

Question 3: How does the addition of LCF affect the properties of PPS?

Answer: The LCF significantly enhances the mechanical strength and stiffness of PPS, making the composite more durable and suitable for demanding applications.

-

Question 4: Are PPS LCF Composites difficult to process?

Answer: Processing can be challenging due to their high performance characteristics, but with the right techniques and equipment, it is manageable.

-

Question 5: What are the cost implications of using PPS LCF Composites compared to traditional materials?

Answer: PPS LCF Composites tend to be more expensive than some traditional materials. However, their superior performance and longer lifespan can often outweigh the initial cost in certain applications.

-

Question 6: What are PPS LCF Composites?

Answer: PPS LCF Composites are a type of polyphenylene sulfide long fiber reinforced composites. It combines the excellent properties of PPS resin, such as high temperature resistance, chemical corrosion resistance, and good mechanical properties, as well as the higher strength and stiffness brought by long fiber reinforcement. For example, in the aerospace field, it can be used to manufacture lightweight components; in the automotive industry, it can be used for high-performance components around the engine.

-

Question 7: What are the main advantages of PPS LCF Composites?

Answer: Its main advantages include excellent heat resistance, which can maintain stable performance in high-temperature environments; good mechanical strength and stiffness, which can withstand large loads; and excellent chemical corrosion resistance, which can resist the erosion of various chemicals. For instance, in the equipment manufacturing of chemical plants, it is widely used because it can tolerate various chemical solvents; in the field of electronics and electrical appliances, it can be used to manufacture components that work in high-temperature environments due to its good heat resistance.

-

Question 8: How to process PPS LCF Composites?

Answer: Processing PPS LCF Composites usually requires the use of specialized processes and equipment. Common processing methods include injection molding, extrusion molding, and compression molding. When injection molding, it is necessary to pay attention to controlling parameters such as temperature, pressure, and injection speed to ensure the quality of the products. For example, for components with complex shapes, injection molding is an efficient processing method; while for large plates or pipes, extrusion molding may be more applicable.