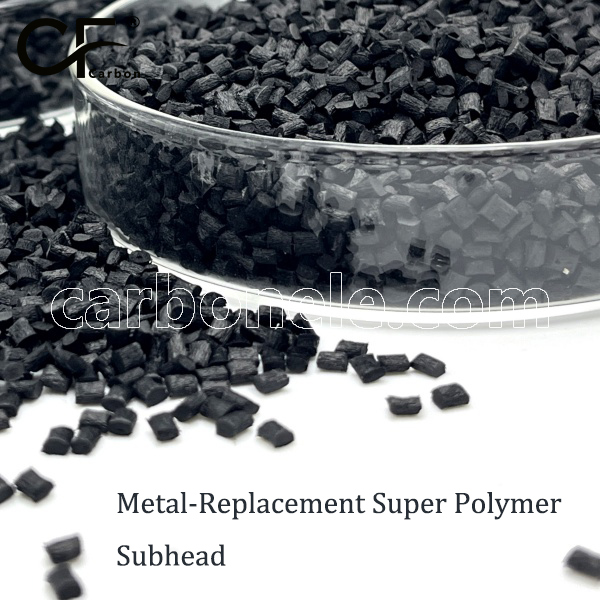

Introduction to PEEK-CF20 Material

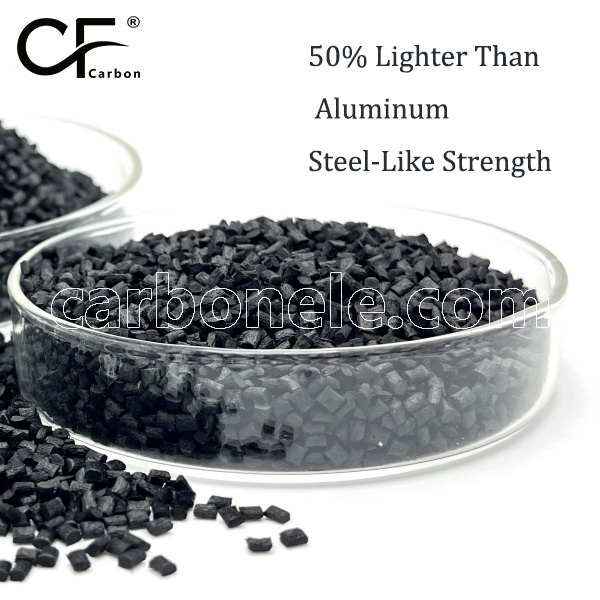

PEEK-CF20 represents a remarkable advancement in high-performance thermoplastics, specifically engineered for demanding industrial applications.

This exceptional material combines the outstanding properties of polyetheretherketone with carbon fiber reinforcement, creating a composite that offers unparalleled performance in challenging environments.

The unique characteristics of PEEK-CF20 make it particularly valuable for semiconductor manufacturing applications where reliability, durability, and precision are paramount.

The semiconductor industry requires materials that can withstand extremely demanding conditions while maintaining strict dimensional stability and purity standards.

It meets these challenges exceptionally well, providing an optimal solution for various semiconductor processing components.

Its exceptional combination of properties makes it the material of choice for manufacturers seeking to improve their production efficiency and product quality.

Exceptional Properties of PEEK-CF20

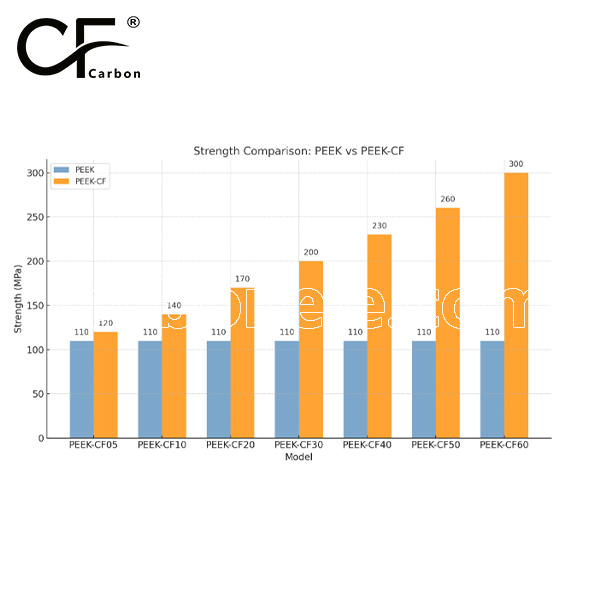

Outstanding Mechanical Strength

PEEK-CF20 demonstrates extraordinary mechanical properties that make it ideal for semiconductor applications. The material maintains excellent structural integrity under various stress conditions, ensuring long-term reliability in demanding semiconductor manufacturing environments.

This robustness allows semiconductor fixtures made from PEEK-CF20 to withstand continuous operation without compromising performance or precision.

The reinforced nature of PEEK-CF20 provides superior resistance to deformation, even when subjected to significant mechanical loads. This characteristic is particularly valuable in semiconductor manufacturing, where maintaining precise tolerances is essential for production success.

The material’s consistent performance ensures that semiconductor components maintain their exact specifications throughout extended periods of use.

Superior Thermal Performance

Thermal management represents a critical aspect of semiconductor manufacturing processes. It exhibits exceptional thermal stability, maintaining its structural integrity and dimensional accuracy across a wide temperature range.

This thermal resistance ensures that semiconductor fixtures perform consistently even when exposed to fluctuating temperature conditions common in semiconductor fabrication processes.

The material’s ability to withstand thermal cycling without degradation makes it particularly suitable for semiconductor applications involving repeated heating and cooling cycles.

It maintains its properties through numerous thermal transitions, ensuring long-term reliability and consistent performance in temperature-varying semiconductor manufacturing environments.

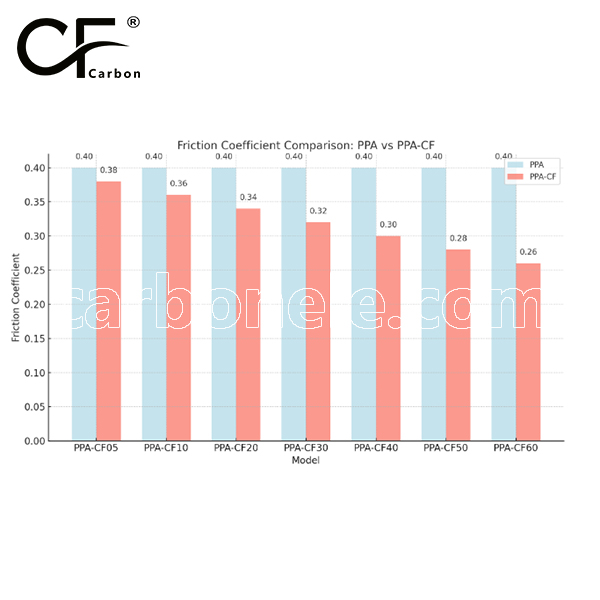

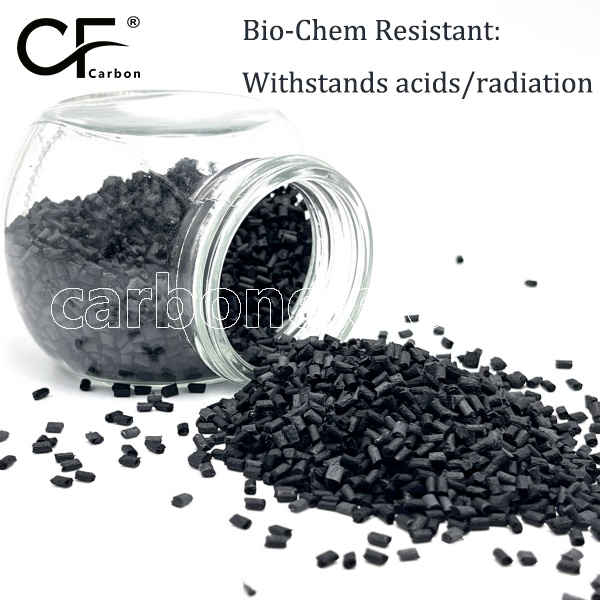

Excellent Chemical Resistance

Semiconductor manufacturing processes often involve exposure to various chemicals and aggressive substances.

It offers remarkable chemical resistance, protecting semiconductor fixtures from degradation when exposed to processing chemicals, cleaning agents, and other potentially corrosive substances used in semiconductor fabrication.

This chemical inertness ensures that PEEK-CF20 semiconductor fixtures maintain their structural integrity and surface characteristics even after prolonged exposure to challenging chemical environments.

The material’s resistance to chemical attack contributes to extended service life and reduced maintenance requirements for semiconductor manufacturing equipment.

PEEK-CF20 in Semiconductor Fixture Applications

Wafer Processing Components

It finds extensive application in wafer handling and processing components within semiconductor manufacturing facilities.

The material’s exceptional properties make it ideal for various wafer processing fixtures that require precise movement, secure holding, and reliable performance throughout the semiconductor manufacturing process.

These components benefit from PEEK-CF20’s combination of strength, stability, and purity characteristics.

The use of PEEK-CF20 in wafer processing equipment ensures minimal particle generation and maximum cleanliness, both critical factors in semiconductor manufacturing environments.

The material’s inherent properties contribute to maintaining the stringent cleanliness standards required for successful semiconductor production, helping manufacturers achieve higher yields and better product quality.

Etching and Deposition Equipment

Semiconductor etching and deposition processes demand materials that can withstand aggressive chemical environments while maintaining precise dimensional stability.

It components in etching and deposition equipment provide excellent resistance to chemical attack while ensuring reliable performance throughout extended operational periods.

The material’s stability under these challenging conditions makes it invaluable for semiconductor fabrication processes.

Fixture components made from PEEK-CF20 maintain their structural integrity and dimensional accuracy even when exposed to the harsh conditions typical of semiconductor etching and deposition chambers.

This reliability translates to consistent process results and reduced downtime for semiconductor manufacturers, ultimately contributing to improved production efficiency.

Testing and Inspection Fixtures

Semiconductor testing and inspection procedures require fixtures that provide secure positioning, excellent dimensional stability, and reliable performance.

PEEK-CF20 offers ideal characteristics for these applications, ensuring that semiconductor components are held securely and precisely during testing and inspection processes. The material’s stability guarantees consistent positioning and accurate measurement results throughout extended usage periods.

The use of it in semiconductor testing fixtures contributes to improved measurement accuracy and repeatability, essential factors in quality control processes.

The material’s consistent performance helps semiconductor manufacturers maintain strict quality standards while reducing measurement variability and improving overall process control.

Advantages of PEEK-CF20 for Semiconductor Manufacturing

Enhanced Process Reliability

The implementation of PEEK-CF20 components in semiconductor manufacturing processes significantly enhances overall process reliability.

The material’s consistent performance characteristics ensure that semiconductor fixtures operate predictably and reliably, reducing variability in manufacturing processes. This reliability translates to more consistent semiconductor product quality and improved production yields.

Semiconductor manufacturers benefit from the reduced downtime and maintenance requirements associated with it fixtures.

The material’s durability and resistance to various operational stresses contribute to extended service life and reduced need for frequent replacements or repairs, ultimately supporting continuous semiconductor production operations.

Improved Product Quality

PEEK-CF20 contributes directly to improved semiconductor product quality through its exceptional performance characteristics.

The material’s dimensional stability and consistency ensure that semiconductor manufacturing processes maintain precise tolerances and repeatable results.

This consistency is crucial for achieving high yields and excellent product performance in semiconductor fabrication.

The purity characteristics of PEEK-CF20 help maintain clean manufacturing environments, reducing the risk of contamination that could compromise semiconductor product quality.

The material’s low particulate generation and chemical inertness support the stringent cleanliness requirements essential for successful semiconductor production.

Long-Term Cost Efficiency

While representing a premium material solution, PEEK-CF20 offers significant long-term cost advantages for semiconductor manufacturers. The extended service life of PEEK-CF20 components reduces replacement frequency and associated downtime costs.

The material’s reliability and consistency contribute to improved production efficiency and higher yields, further enhancing cost-effectiveness.

The reduced maintenance requirements of PEEK-CF20 fixtures lower overall operational costs while minimizing production interruptions.

Semiconductor manufacturers benefit from the combined advantages of improved performance, extended component life, and reduced maintenance needs, making PEEK-CF20 a economically sound choice despite its premium nature.

Manufacturing with PEEK-CF20 Material

Precision Machining Capabilities

PEEK-CF20 responds exceptionally well to precision machining processes, allowing manufacturers to create complex semiconductor fixture components with tight tolerances and excellent surface finishes.

The material’s machining characteristics enable production of intricate features and precise geometries required for advanced semiconductor manufacturing applications.

The stability of PEEK-CF20 during machining processes ensures that manufactured components maintain their dimensional accuracy and structural integrity.

This machining precision is essential for semiconductor fixtures that must operate with extreme accuracy and reliability in demanding manufacturing environments

Customization Opportunities

The versatility of PEEK-CF20 allows for extensive customization to meet specific semiconductor manufacturing requirements.

Manufacturers can tailor PEEK-CF20 components to address unique application needs, environmental conditions, and performance specifications. This flexibility enables optimal solutions for various semiconductor manufacturing challenges.

Custom PEEK-CF20 semiconductor fixtures can be engineered to provide specific performance characteristics, interface requirements, and operational capabilities.

This customization potential allows semiconductor equipment manufacturers to develop optimized solutions that maximize process efficiency and product quality.

Quality Assurance and Performance Validation

Rigorous Testing Protocols

PEEK-CF20 semiconductor components undergo comprehensive testing to validate their performance characteristics and ensure reliability in actual operating conditions.

These testing protocols verify that the material maintains its properties under various environmental conditions and operational stresses typical of semiconductor manufacturing processes.

The validation process includes assessments of mechanical performance, thermal stability, chemical resistance, and long-term reliability.

These rigorous testing procedures ensure that PEEK-CF20 components consistently meet the demanding requirements of semiconductor manufacturing applications.

Continuous Performance Monitoring

Ongoing performance monitoring ensures that PEEK-CF20 semiconductor fixtures continue to meet operational requirements throughout their service life.

This continuous assessment helps identify potential issues before they impact semiconductor manufacturing processes, supporting uninterrupted production and consistent product quality.

Regular performance evaluation also provides valuable data for further optimization of PEEK-CF20 components and semiconductor manufacturing processes.

This continuous improvement approach helps maximize the benefits of using PEEK-CF20 in semiconductor applications.

Conclusion: The Future of Semiconductor Manufacturing with PEEK-CF20

PEEK-CF20 represents a significant advancement in materials technology for semiconductor manufacturing applications.

Its exceptional combination of properties makes it ideally suited for the demanding requirements of semiconductor fixture applications.

The material’s outstanding performance characteristics contribute to improved process reliability, enhanced product quality, and long-term operational efficiency.

As semiconductor manufacturing continues to advance toward more demanding processes and stricter requirements, materials like PEEK-CF20 will play increasingly important roles in supporting these technological advancements.

The continued development and optimization of PEEK-CF20 applications in semiconductor manufacturing will contribute to further improvements in production efficiency, product quality, and overall manufacturing capability.

The adoption of PEEK-CF20 semiconductor fixtures represents a strategic investment in manufacturing excellence, supporting the ongoing advancement of semiconductor technology and its applications across various industries.

If you want to get more information , you can visit our YouTube.